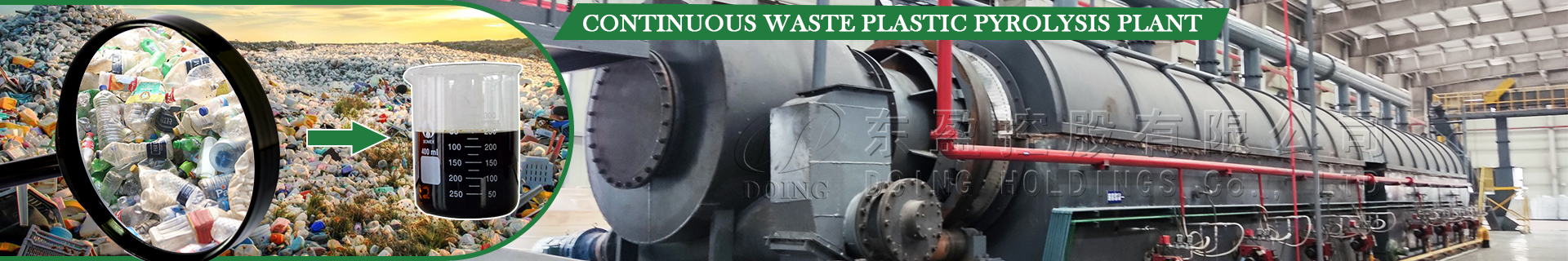

Continuous Waste Plastic Pyrolysis Plant

As a leading manufacturer specialized in waste tire/plastic/rubber pyrolysis plant more than 10 years, Henan Doing has developed the continuous waste plastic pyrolysis plant. This continuous waste plastic pyrolysis plant can continuously process plastic into plastic pyrolysis oil and carbon black without stop. All the continuous waste plastic pyrolysis plant is controlled by PLC(programmable logic controller), so it is very easy to operate it and our customers can save much cost of time and labor.

Processing Capacity: 20T/30T/50T, custom

End Products: Plastic oil, carbon black

Core Components: Pyrolysis reactor, condenser, PLC

Certificates: CE, ISO, SGS

- Email:

- Phone/WhatsApp/WeChat:

+86-135-2669-2320

Raw Material

The suitable raw materials of DOING continuous waste plastic pyrolysis plant can be polythene, polypropylene(PP), polystyrene(PS), ABS...

For Pure PP, PE, PS, ABS, the oil yield can be over 90%, but for mixed common plastic, the oil yield is usually from 30% to 50%,for paper mile, the oil yield is 30% for wet paper mile, 60% for dry paper mile.

| Raw material | Picture | Oil Yield |

| Pure PE |

|

50%-95% |

| Pure PP |

|

50%-90% |

| Pure PS |

|

75%-90% |

| Pure ABS |

|

40% |

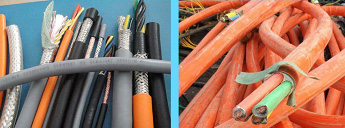

| Pure Plastic cable |

|

80% |

| Plastic bag |

|

50% |

| PVC |

|

Not available |

| PET |

|

Not available |

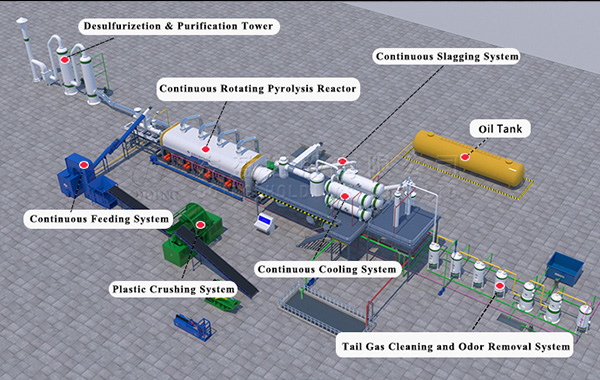

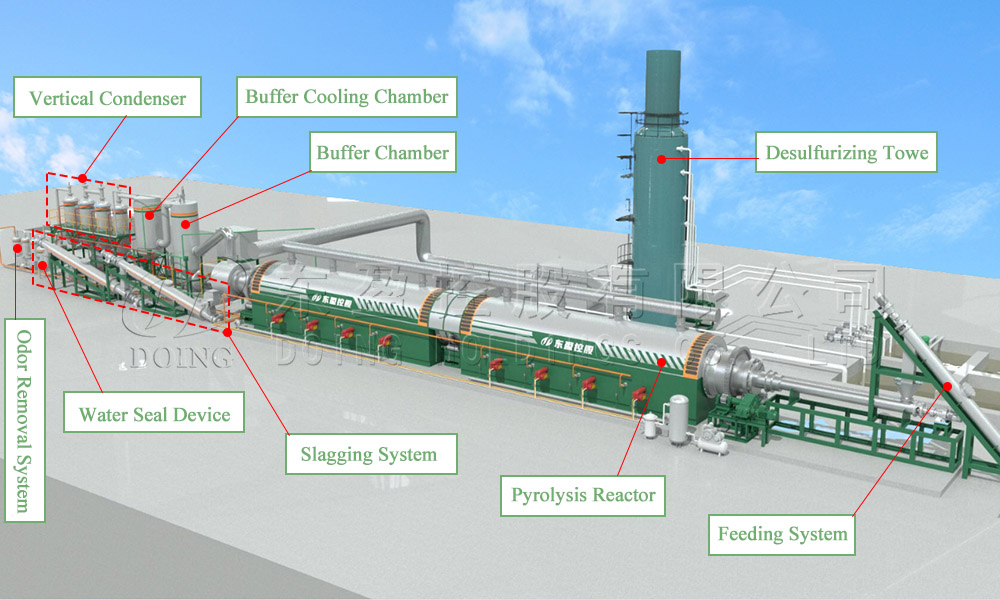

Main Working Process

To keep continuous feeding and discharge system, it requires the waste tyres should be in small size. So before continuous pyrolysis process, the waste tyres should be shredded into small pieces. As for detailed process, please check as below.

- 1. All available plastic can be shredded by plastics crusher, and then feed plastic granules directly into continuous plastic pyrolysis plant through the feeding door.

- 2. Our feeding door is with screw inside, so it can help you easily convey the plastic granules into our reactor No 1, then all the plastic can be decomposed under the high temperature through reactor No 1 to reactor No 2,then to reactor No 3...Until all the plastic fully pyrolysed, then all the carbon black powder will be discharged automatically to the carbon black tank.

- 3. The obtained oil gas will be cooled by circulation water and the extra pyrolysis gas will be recycled through pipes into the burners for heating again. In our continuous waste plastic pyrolysis plant, the water circulation system and extra pyrolysis gas recycling system will help you save much fuel and water resource. In this way, our continuous plastic pyrolysis plant can minimize your cost and maximize your profits.

Technical Data of Continuous Waste Plastic Pyrolysis Plant

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

Unique Advantages of DOING Continuous Waste Plastic Pyrolysis Plant

- 1. The use of PLC control system, a high degree of automation, saving manpower.

- 4. Accurate calculation system ensures full cracking and high oil yield.

- 2. Really realized 24 hours of continuous work, continuous feeding from one end, continuous discharging/dumping at the other end.

- 5. The pyrolysis reactor adopts an internal rotation device and does not need to be stopped at regular intervals to replace the sealing material.

- 3. Single machine processing capacity, small footprint. Cutting costs.

- 6. The heating method is indirect heating, long service life.

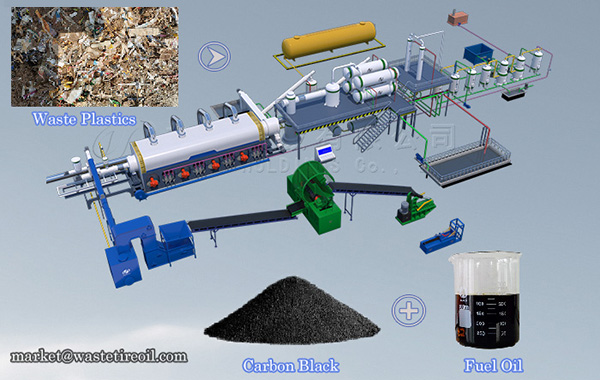

End Products And Uses of Continuous Waste Plastic Pyrolysis Plant

The end products of DOING continuous waste plastic pyrolysis plant mainly include fuel oil, carbon black and little combustible gas. Their specific uses are as follows.

| Pyrolysis Oil |

|

1. can be sold directly. 2. Reprocessed into diesel and gasoline by waste oil distillation machine. 3. can be used as industrial fuel materials for burning. |

| Carbon Black |

|

1. can be sold directly. 2. Reprocessed into high quality carbon by the carbon black processing plant. 3. make carbon brick by briquetting machine. |

| Combustible Gas |

|

can be recycled as fuel to heat the reactor |

Project Case

contact us

CONTACT USPhone:

+86-135-2669-2320WhatsApp:

8613526692320E-mail:

market@doingmachinery.comWechat: