Waste Oil Recycling to Diesel Plant

Waste oil recycling to diesel plant can convert tire oil, plastic oil, and waste engine oil to diesel. In some country, waste oil recycling to diesel plant also named waste oil distillation machine, distillation equipment, it just name different, but have same functions.

Processing Capacity: 5T/10T/15T/20T, custom

End Products: Diesel, asphalt

Core Components: Distillation reactor, condenser

Certificates: CE, ISO, SGS

- Email:

- Phone/WhatsApp/WeChat:

+86-135-2669-2320

Raw Material

For our waste oil recycling to diesel plant, the applicable raw material can be any kinds of waste oil, such as tire oil, plastic oil, waste engine oil, black oil, heavy oil, motor oil, etc.

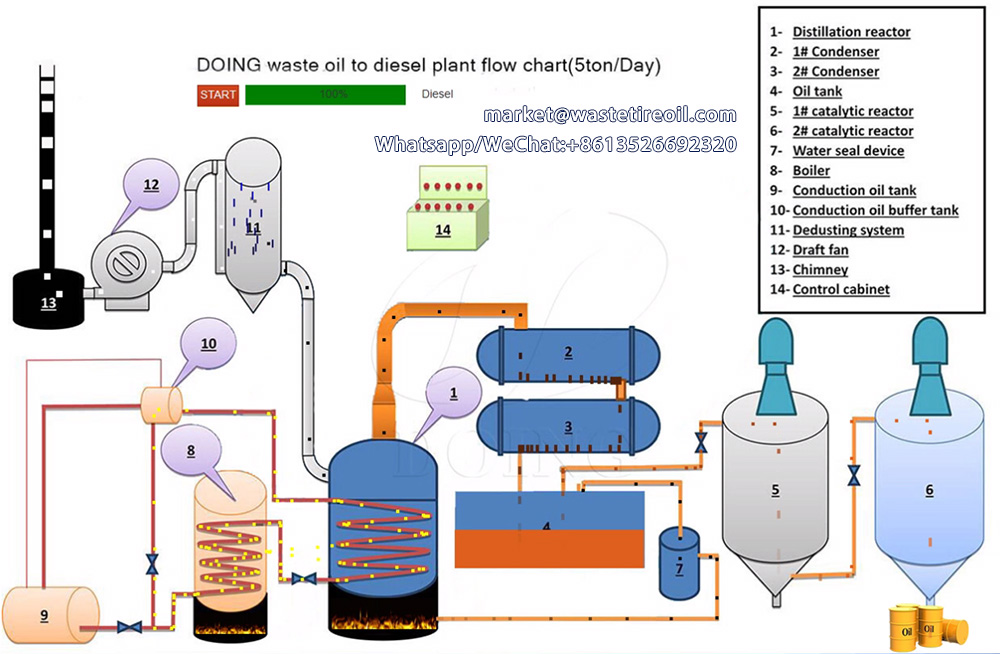

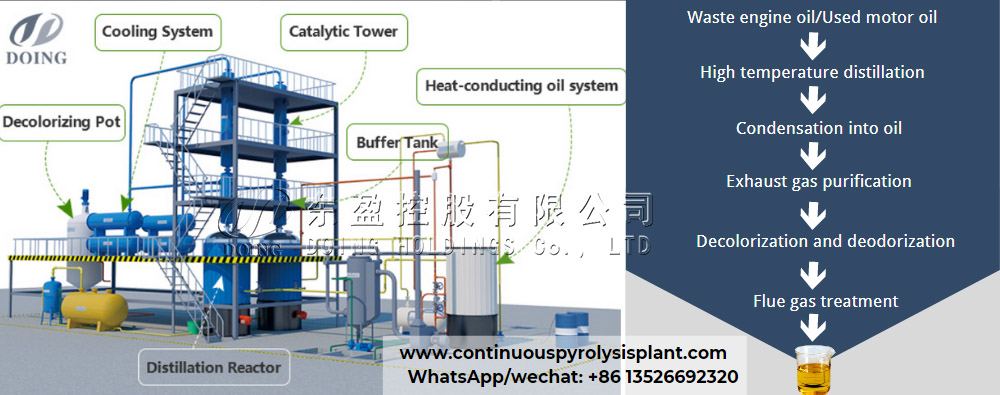

Working Process of Waste Oil Recycling to Diesel Plant

- 1. Pump waste oil into the vertical reactor of the waste oil recycling to diesel plant;

- 2. Heat the vertical reactor with heat conduction oil heating together with the bottom fuel heating. When reaching a certain temperature, the oil gas will be vaporized out and separated from the impurities.

- 3. The oil gas will be cooled into liquid oil by the condensers, and the liquid oil will be collected into the distillate storage tank.

- 4. The non-condensing oil gas after passing the distillate tank and water seal device will be recycled to heat the reactor of waste oil recycling to diesel plant.

- 5. Adding clay into the liquid oil can make the color of oil more bright and transparent. After filtering, the qualified diesel oil will be collected into the oil tank.

- 6. Collect the asphalt from the vertical reactor.

Technical Parameters of Waste Oil Recycling to Diesel Plant

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire oil, plastic oil,engine oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180m² |

Main Advantages of Waste Oil Recycling to Diesel Plant

- 1. The heat transfer heating system can make the distillation process more efficient, shorter in time and less in fuel.

- 2. The design of vertical reactor can realize asphalt automatic discharging, which is convenient and more quick.

- 3. The circulating water cooling system consumes almost no water.

- 4. The diesel oil cleaning system will enable you to get high-quality diesel oil.

- 5. The efficiency of waste oil recycling to diesel plant is high, and the diesel oil yield is as high as 90%.

- 6. Figured with exhaust gas treatment equipment, the whole process of waste oil recycling to diesel plant is environmentally friendly, and there is no waste pollution.

Final Products Applications

There are two main products of waste oil recycling to diesel plant, one is non-standard diesel oil, and the other is asphalt. Moreover, these two products both have a wide range of applications.

| Name | Usage |

| Diesel | It can be directly used in tractors, trucks, ships, boilers, diesel generators, etc. |

| Asphalt |

1. It can be used for paving; 2. It can also be further refined by asphalt plant to get fuel oil. |

Project Case

contact us

CONTACT USPhone:

+86-135-2669-2320WhatsApp:

8613526692320E-mail:

market@doingmachinery.comWechat: