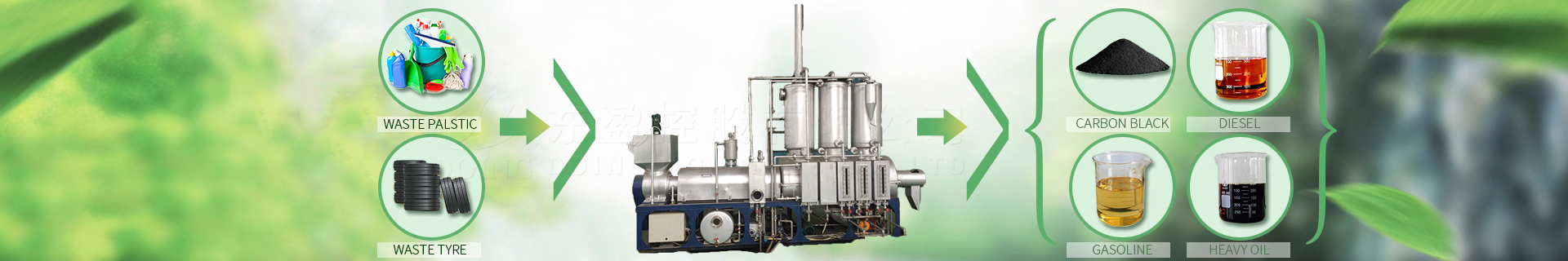

Waste Tyre & Plastic to Diesel Plant

Waste tyre & plastic to diesel plant is a new design we DOING Company just developed. The main advantage is it could directly extract diesel and gasoline separately from waste tyres or plastics. This waste tyre & plastic to diesel plant adopts fully automatic PLC control system, easy for operation. And the whole line is a one piece design, which has small land occupy size.

Processing Capacity: 5T/10T/15T, custom

End Products: Diesel, gasoline, heavy oil, carbon black

Core Components: Pyrolysis and distillation reactor, condenser, PLC

Certificates: CE, ISO, SGS

- Email:

- Phone/WhatsApp/WeChat:

+86-135-2669-2320

DOING Waste Tyre & Plastic to Diesel Plant for Difffernet Raw Materials

Main Working Process of Waste Tyre & Plastic to Diesel Plant

-

1. Feeding

Shredded or crushed the raw material into small pieces less than 3-5cm, then put them into transmission device. Through the transmission device, they are automatically and continuously fed into the waste tyre & plastic to diesel plant.

-

2. Preheating to remove Dioxin

As we all know that Dioxin is very easy to be produced from many kinds of waste burning process, especially chlorine substance, like PVC plastics, paper-mill waste, household garbage, etc. And the emission of Dioxin will cause serious problems to the environment and human body, thus it need to be seriously disposed and removed before released to the air.

-

3. Heating and pyrolysis

After remove the Dioxin, the raw materials in the pyrolysis reactor will be for further heating and pyrolzed to oil gas.

-

4. Catalysis

The catalysis process is mainly adopted to purify oil gas and get the maximum light oil.

-

5. Fractionation

Fractionation process is mainly for getting different end product in different temperature.

-

6. Cooling

The resulting different oil gas, through the action of the cooling system, will be cooled into liquid oil and collected in the oil tank.

-

7. Extra gas recycling and collection

The main component of tail gas is methane, which is a non-condensable gas and also a good fuel. In order to ensure the safe operation of the waste tyre & plastic to diesel plant, we will not discharge the exhaust gas to the atmosphere, but will recycle the exhaust gas to the hearth of the heated reactor to assist the heating as fuel. This not only ensures that the exhaust gas does not pollute the air, but also helps the customer to save the heating fuel.

-

8. Carbon black slagging

Carbon black will be collected in carbon black tanks through an automatic slag removal system without causing dust in the workshop.

Equipment Specification of Waste Tyre & Plastic to Diesel Plant

| Item | Content | ||

| Inputs | Waste tire, plastic, medical waste, multiple solid waste | ||

| Outputs | Diesel, gasoline, heavy oil, carbon black, uncondensable gas | ||

| Model | Capacity | Power | Weight |

| 1.5T/D | 15KW | 6T | |

| 2.5T/D | 20KW | 8T | |

| 5T/D | 35KW | 10T | |

| 10T/D | 50KW | 12T | |

| 15T/D | 65KW | 15T | |

| 20T/D | 80KW | 20T | |

| Machine type | Continuous machine | ||

| Operation system | Fully automatic PLC control system | ||

| Reactor material | Q345R/Q245R/310S+boiler plate/stainless plate | ||

| Thickness | 12mm/14mm/16mm | ||

| Heating type | Indirect heating | ||

| Heating fuel | Fuel oil, LPG, Natural gas | ||

| Cooling type | Circulating water cooling | ||

| Land occupy size | Take 10T/D machine as an example, it’s about 150 - 200m2( Width:5-10m, Length:15-20m, Height: 8m) | ||

| Required workers | 1-2 workers per shift | ||

| Remarks | The bigger plant like 30T/D, 50T/D,100T/D could be made according to order. | ||

Main Advantages of Waste Tyre & Plastic to Diesel Plant

-

1. High efficiency

It can efficiently convert waste to diesel, gasoline and heavy oil in the same time and separately.

-

2. Easy control

This waste tyre & plastic to diesel plant is equipment with smart PLC control system. It is easy to operate and control.

-

3. Continuous working line

Fully automatic continuous feeding and slagging system, which can keep feeding, heating, discharging and getting oil output every second without stop.

-

4. No pollutant emissions

Waste tyre & plastic to diesel plant is fitted with advanced dedusting and odor removal system which can remove Dioxin advance, so that emissions is pollution free.

-

5. Better meet clients’ different request

DOING waste tyre & plastic to diesel plant has the catalysis system which could adjust the quantity of diesel and gasoline according to customer’s demand.

-

6. Energy saying

Waste tyre & plastic to diesel plant has the extra gas collection system which can save heating fuel.

Output Products & Applications of Waste Tyre & Plastic to Diesel Plant

There are two main products of waste oil recycling to diesel plant, one is non-standard diesel oil, and the other is asphalt. Moreover, these two products both have a wide range of applications.

-

1. Diesel

Can be used as heating purpose or as fuel in heavy engines.

-

2. Gasoline

Can be used as heating purpose or as fuel in heavy engines.

-

3. Heavy oil

It is used as heating material in industry, like cement factories, boilers, etc.

-

4. Carbon black

It can be briquetted into pellet as heating material to replace charcoal, wood, etc. Besides, it can be refined to small meshes for making shoe soles, paint, new rubber, etc.

contact us

CONTACT USPhone:

+86-135-2669-2320WhatsApp:

8613526692320E-mail:

market@doingmachinery.comWechat: