Q:What the advatage of recycle waste plastic?

A:

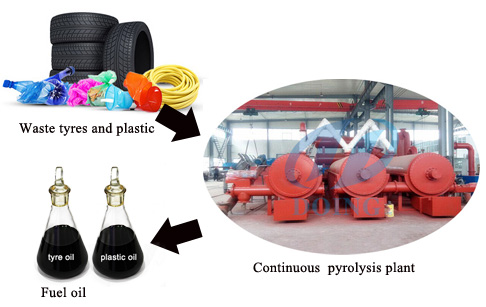

We have the chance to introduce you the green technology for waste recycling. Waste plastic recycling machine After being processed, all the plastic will be fully recycled, most percent are turned into fuel oil, the others are carbon black and fuel...

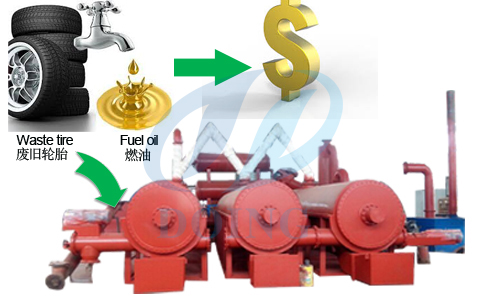

Q: How to make furnace oil from tyres?

A:

Shredded tyres go into the continuous waste tyre pyrolysis plant, will firstly go through a mutiple pyrolysis reactor system to be pyrolyzed into oil gas. And oil gas will be cooling down to liquid oil through the cooling system. The residues (carbon ...

Q:Why recycling waste plastic is important ?

A:

Waste plastic has become the most common material since the beginning of the 20th century and modern life is unthinkable without it. Unfortunately, what makes it so useful, such as its durability, light weight and low cost, also makes it problematic ...

Q:Advantages of continuous automatic waste tyre oil plant

A:

Continuous automatic waste tyre oil plant is a kind of pyrolysis technology that convert waste tyre to fuel oil ,carbon black and steel wire. Continuous automatic waste tyre oil plant is a significant improvement based on the existing intermittent...

Q:What is continuous automatic plastic into oil machine?

A:

Continuous automatic plastic into oil machine is a significant improvement based on the existing intermittent plastic into oil machine at home and abroad, continous automatic plastic into oil machine fully realize the automatic operation ,continous ...

Q:How to recycle waste tyre by continuous waste tyre pyrolysis plant ?

A:

Cotinuous waste tyre pyrolysis plant usually adopts advanced pyrolysis technology to recycle waste tyre. In the tyre pyrolysis process, waste tyres will be converted into tyre oil, carbon black, steel wire and so on. Namely, you can get one ton fuel o...

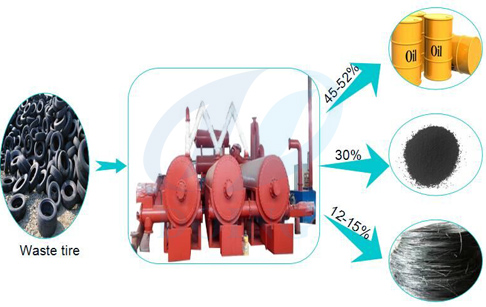

Q:What about continuous waste tyre pyrolysis output?

A:

Through continuous improvement and constant technology upgrading, we have designed continuous waste tyre pyrolysis plant which can convert tyre into useful resources more efficiently. This series daily processing capacities range from 30 to 100tons. ...

Q:Doing continuous tyre pyrolysis plant is environmental friendly?

A:

The pollution of waste tyre pyrolysis plant mainly comes from the four aspects: waste water, waste gas, waste slag and noise pollution. A. Waste water: The waste water consists of two parts: condensing water and dust removing water. The condensing wa...

Q:What can we get from 10T of waste tyres ?

A:

Oil is the main products of scrap tires pyrolysis plant, widely used in industrial area, for example used for heating boiler and other kinds of equipment. 10 ton if scrap tires through DOING waste tyres pyrolysis plant can produce about 4.5 ton oil, ...

Q:How to build a waste oil distillation plant factory?

A:

Prepare the raw material: Such as waste engine oil, waste plastic oil, and waste tyre oil, waste motor oil. Collect the raw material in a low price. The oil yield rate differs depends on different material: Name Oil yield Waste engine oil 85%-90% Wast...

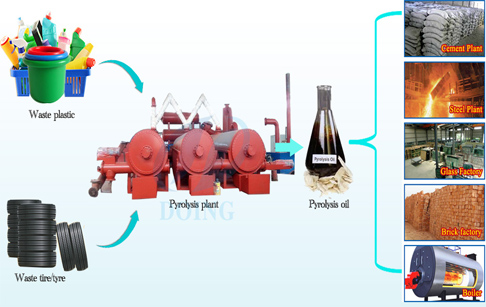

Q:What is pyrolysis oil application?

A:

Pyrolysis oil is a fuel mainly extracted from waste tyre, waste plastic. It is a fuel has heating value; it is a good alternative energy to traditional limited energy. The pyrolysis oil can be used in glass factory, cement factory, steel factory, and ...

Q:Is the pyrolysis plant environmental harmful?

A:

The pyrolysis plant is of no pollution to the environment. If we operate the pyrolysis plant well the pyrolysis plant is clean without any air commission....