Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

Advantages of continuous automatic waste tyre oil plant

2016-09-02 / Continuous Pyrolysis plant / Leave Message / Chat Online

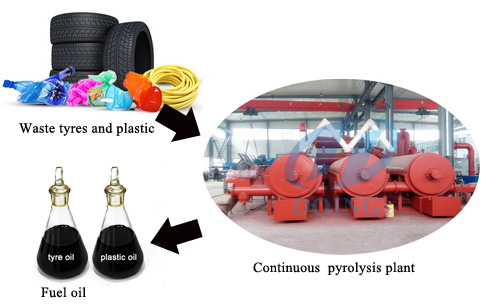

Continuous automatic waste tyre oil plant

Continuous automatic waste tyre oil plant advantage

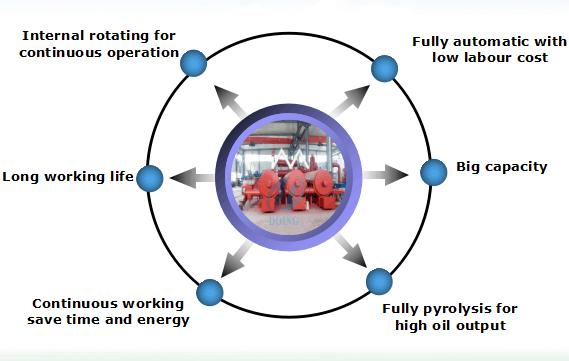

1.Fully automatic with low labour cost

Our continuous automatic waste tyre oil plant is controled by PLC system with automatic feeding and discharge system, which only need 1-2 worker for operating the PLC or computer is ok.

2.Fully pyrolysis for high oil output

Our Continuous automatic waste tyre oil plant adopts mutiple reactor design which can make fully pyrolysis of waste tires, thus to get high oil output.

3.Big capacity

Also due to continuous feeding and discharge system, and unique mutiple reactor design, our Continuous automatic waste tyre oil plant can process at least 10 tons waste tires per day, up to 100T/D.

4.Internal rotating for conitnuous operation

For external rotating system, you have to change the sealing material every three days, thus cannot achieve the real sense of continuous process. But our continuous waste tyre pyrolysis reactor adopts internal rotating method, which no need to worry about the sealing of the external rotating system.

5.Continuous working save time and energy

6.Long working life

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.