Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

Product

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

2024-03-03 / In America / Leave Message / Chat Online

In February 2024, DOING's waste plastic pyrolysis unit and acid-alkali catalytic distillation unit were successfully installed and commenced stable operation in Mexico. These installations are dedicated to the environmental processing and recycling of plastic waste generated by paper mills, at the same time achieving diesel extraction.

Waste plastic pyrolysis distillation units in Mexico

Waste plastic pyrolysis distillation units in Mexico

Feedback videos from our Mexican clients showcased the stable operation and smooth oil output of the waste-to-diesel pyrolysis and distillation units. This not only underscored the maturity of DOING's technology but also highlighted our capability to dynamically adjust operations when dealing with high moisture and impurity content typical of paper mill plastics during actual usage.

The Mexican client operates several paper mills that generate substantial amounts of mixed plastics daily. Seeking to leverage resource recovery, they opted to invest in a plastic-to-diesel recycling initiative. Based on their requirements, Henan DOING Company offered a 15-ton-per-day (TPD) waste plastic pyrolysis unit solution.

The oil yield of the 15 TPD paper mill plastic pyrolysis unit can be affected by the moisture content of the feedstock. While wet material yields oil at a rate of 15-30%, dry materials can achieve yields up to around 50-60%. DOING recommended pre-treatment for drying or dehydrating the plastics prior to pyrolysis. Thus, up to 9 tons of plastic oil could be distilled from 15 tons of water-washed paper mill waste. The plastic pyrolysis oil is widely used as heating fuel in boilers, furnaces, steel mills, cement plants, and brick factories. To enhance the quality and utilization of the plastic oil, Henan DOING further proposed a complementary solution—a 10 TPD acid-alkali catalytic distillation unit paired with the 15 TPD waste plastic pyrolysis unit, transforming plastic oil into diesel. The resulting diesel serves as fuelfor diesel generators, truck fleets, tractors, and heavy machinery, amplifying economic value.

Waste plastic to diesel machine to Mexico delivery picture

Waste plastic to diesel machine to Mexico delivery picture

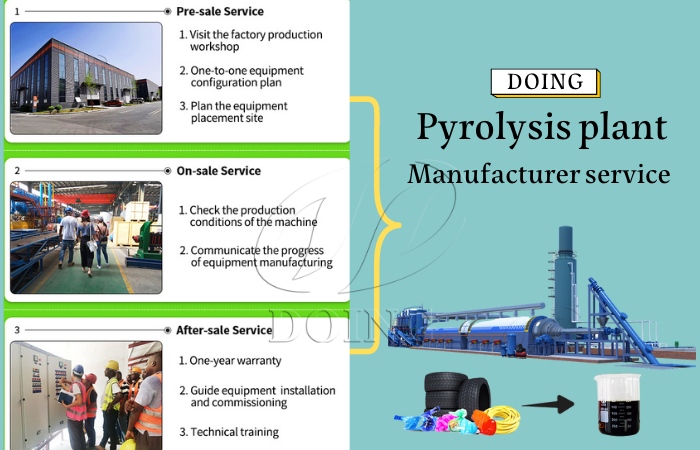

Our Mexican client paid attention to the installation services and operational realities of the plastic-to-diesel facility. Our sales manager shared an inspection report from another successful Mexican pyrolysis unit project. And we offer all-around technical services to meet our customers' requirements, including machine installation and worker training. At that time, we just had an installation engineer from DOING in South America, providing on-site guidance for a pyrolysis project setup. This alleviated the Mexican client's concerns regarding after-sales service!

Waste plastic pyrolysis distillation unit manufacturer

Waste plastic pyrolysis distillation unit manufacturer

Henan DOING Company won the recognition and good feedback in waste pyrolysis and distillation plants from customers across Mexico and has extended its reach to over 90 countries and regions worldwide. For more eco-friendly waste-to-fuel recycling solutions, please send us your requirements, and our professional sales and engineer team will customize appropriate pyrolysis distillation units for you.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.