Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

What treatment steps are involved in refining crude waste oil into energy use?

2021-09-27 / Oil Refining Machine / Leave Message / Chat Online

Crude waste oil which can be refined into energy use includes tire/plastic pyrolysis oil, waste engine oil and oil sludge. Using crude waste oil refining machine to refine crude waste oil mainly need two treatment steps: distillation and decolorization.

Waste oil refining machine

Waste oil refining machine

The introduction of distillation:

Distillation is to purify the crude oil by heating and condensing. The specific treatment steps in distillation process is divided into three steps.

1. Heat the reactor to make the oil gas out. Heating is divided into two stages: first heating stage uses conduction oil and second heating stage uses natural gas or other fuel.

2. Catalyzing can make the distillation time be shortened and the effect of distillation be also better.

3. Condensing is to use condensation system to make the oil gas be condensed into oil tank. The oil in this part still belongs to semi-finished oil.

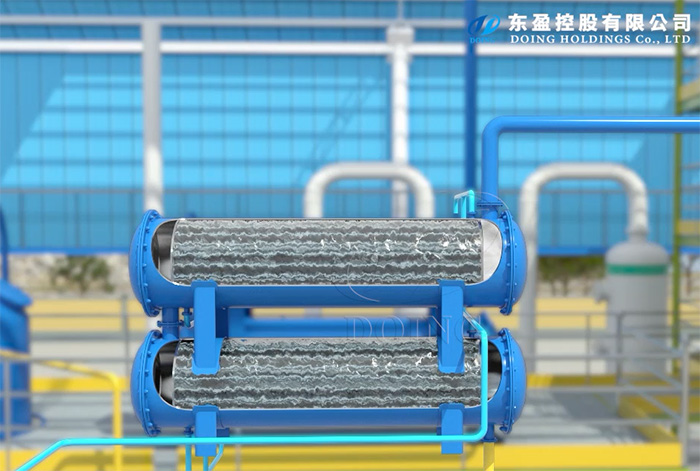

Condensation system

Condensation system

The introduction of decolorization:

Decolorization is to light the oil color by the adsorption ability of white clay. The specific treatment steps are as following introduction.

1. Vacuumize the decolorization system

2. Pump the oil into decolorization system and heat the oil into certain temperatrue.

3. Add white clay to the oil and react for some time.

4. Use leaf filter to filter the waste white clay out.

After treatment steps above, you can get good clear and light yellow color diesel and asphalt. The diesel refined by crude waste oil machine can be directly used for agricultural machinery, ships, diesel generators, large diesel engine, mining machinery, forklift truck excavator and other large heavy machinery, can also be applied to power plants, boilers, kiln factory, cement and so on as fuel. Therefore, you can sold diesel to these plants for making money. As for asphalt, you can directly sold to the enterprise which specialize in constructing roads for paving.

The application of diesel

The application of diesel

Over the years, the crude waste refining machine we provided to customers has always been high efficiency, stable performance and long service life. The distillation machine of Doing can help you get good quality diesel and improves your economy benefits. If you want to know more information about crude waste refining machine, we look forward to cooperating with you.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.