Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

Product

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

15TPD waste tyre pyrolysis plant project in Brazil

2024-04-25 / In America / Leave Message / Chat Online

In April, 2024, our Brazilian customer had good news for us that the waste tyre pyrolysis plant he previously ordered from DOING has been successfully put into operation and received satisfactory oil content.

Project introduction

This project has the processing capacity of 15TPD, which means it can process about 15 tons of waste tyres per day. As the machine supplier and cooperation partner of the Brazilian customer, DOING provides comprehensive services for the customer from suitable machine selection to installation&operation guidance to ensure the successful carrying of the project.

| Waste tyre pyrolysis plant project | |

| Project location | Brazil |

| Processing capacity | 15TPD |

| Raw material | Waste tyres |

| Final products | Fuel oil, carbon black |

| Applications | Fuel oil: 1) Be used in cement factories, steel factories, ships, trucks, boiler heating, etc. 2) Be refined to diesel, which can be used in heavy oil machinery, boiler heating, generator, etc.Carbon black: 1) Be used as heating fuel in cement&steel&aluminum factory; 2) Be refined to be used in rubber industry or used as paints and inks; |

| Equipped devices | Feeding system, pyrolysis reactor, cooling system, buffer tank, tail gas cleaning system, desulfurization tower, oil tank, slagging system, exhaust gas collect&storage system, etc. |

| Project advantages | High work efficiency to provide alternative fuel energy for customer; useful final products to generate huge profits; environmentally friendly green technology to avoid pollution; |

Customer introduction

The Brazilian customer has an aluminum factory, which needs to consume lots of fuel energy. To seek for suitable and cost-effective alternative fuel energy, the Brazilian customer made a brief survey on some alternative fuels in the market, and finally he decided to invest in the waste tyre pyrolysis plant project. After receiving the inquiry from the Brazilian customer, our sales manager made a comprehensive learning about the core demand of the Brazilian customer-obtain abundant alternative fuel energy. So our sales manager introduced the high work efficiency, high oil yield and other unique designs and advantages of our pyrolysis plant to our customer, and finally, we reached friendly cooperation.

DOING waste tyre pyrolysis plant for sale

DOING waste tyre pyrolysis plant for sale

Delivery site

After about four months, this set of waste tyre pyrolysis plant finished the manufacturing. After the sincere inspection and package, this set of waste tyre pyrolysis plant was delivered to Brazil. The following are some delivery pictures of this machine:

Delivery pictures of waste tyre pyrolysis plant to Brazil

Delivery pictures of waste tyre pyrolysis plant to Brazil

Installation site

After arriving in Brazil, DOING engineer gave detailed and patient guidance and training the Brazilian customer based on the actual project progress and site arrangements. Finally, this set of waste tyre pyrolysis plant was successfully installed in about two months.

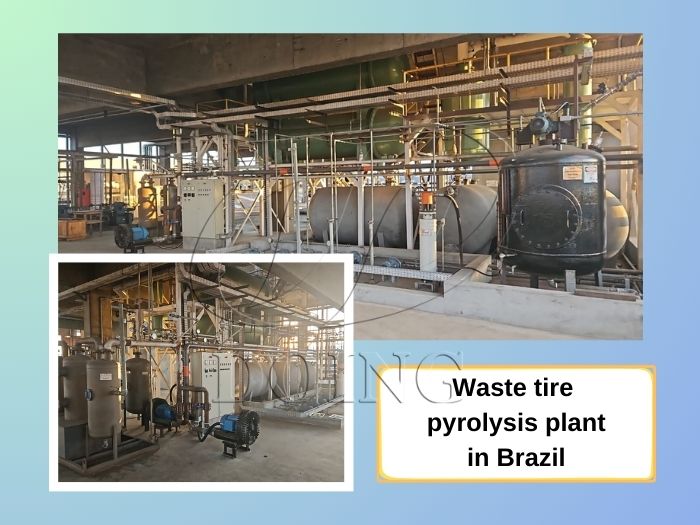

Installation pictures of waste tyre pyrolysis plant in Brazil

Installation pictures of waste tyre pyrolysis plant in Brazil

After the waste tyre pyrolysis plant was successfully installed, DOING engineer has been paying close attention to the subsequent operation of the waste tyre pyrolysis plant. And in April, 2024, our Brazilian customer sent some pictures and videos of the machine running site and displayed the good quality of the obtained fuel oil. According the real feedback of the Brazilian customer, he was greatly satisfied with the work performance of the machine. The following is the real feedback video of the obtained fuel oil taken by our Brazilian customer:

DOING has cooperated with thousands of customers in various countries and regions in the past 14 years, apart from the waste tyre pyrolysis plant, we also researched other machines, like waste plastic pyrolysis plant, oil sludge treatment machine, waste oil distillation machine, etc. If you are interested in our machines, welcome to send your inquiry to us!

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.