Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

What machines are used to recycle plastic into oil?

2023-05-25 / Continuous Pyrolysis plant / Leave Message / Chat Online

Pyrolysis technology can break down large molecules of plastics into smaller molecules of fuel oil, combustible gas and carbon black in an oxygen free environment, which not only causes no pollution to the environment but also recycles the energy effectively.

DOING has developed three types of waste plastic pyrolysis machine to recycle plastic into oil, which adopts the newest technology to improve the final oil yield and quality,

1. Batch-type waste plastic pyrolysis machine

The batch-type waste plastic pyrolysis machine is from 100kg, 500kg to 18T/D and 20T/D, which is suitable for trial running because it needs relatively little money and easier installation.

2. Semi-continuous waste plastic pyrolysis machine

The semi-continuous waste plastic pyrolysis machine is from 1T/D to 20T/D, which has high efficiency because there is no need to cool down before removing the carbon black.

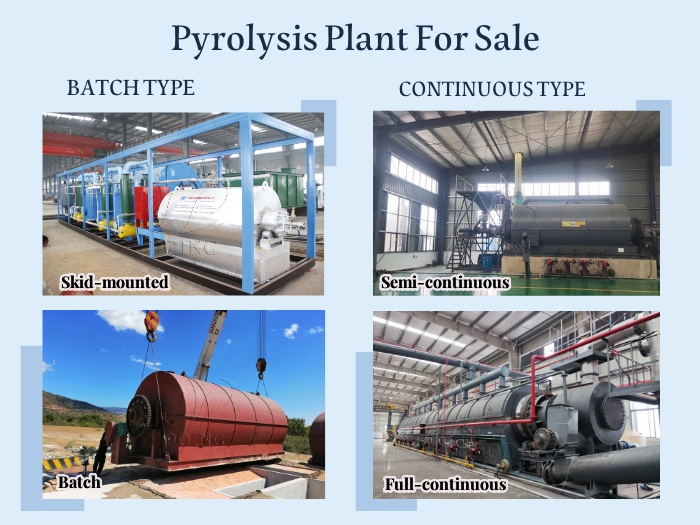

DOING various types of pyrolysis plant for sale

DOING various types of pyrolysis plant for sale

3. Fully continuous waste plastic pyrolysis machine

The fully continuous waste plastic pyrolysis machine is from 15 T/D to 50T/D, which can help you recycle more plastics. It can work continuously to recycle plastic into oil for up to 100 days and costs less labor for its fully automatic PLC control system.

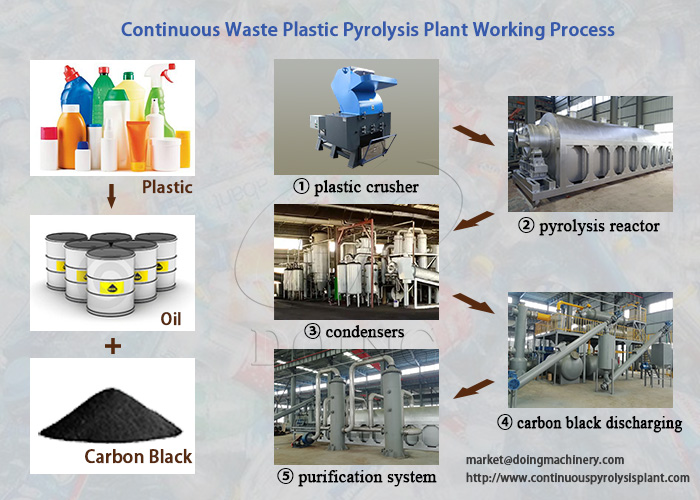

Above three waste plastic pyrolysis machines can obtain the same quality fuel oil with the same configurations and their pyrolysis processes are roughly the same:

Put the plastics into the reactor of the waste plastic pyrolysis machine and heat the pyrolysis machine, then the plastics will be pyrolyzed to oil gas; after passing through the cooling system, the oil gas will be cooled into liquid oil, which is stored in the oil tank.

DOING waste plastic pyrolysis plant working process

DOING waste plastic pyrolysis plant working process

Since the molecular composition of each plastic is different, their oil content is also different. The purer the plastic, the higher the oil content. However, one thing to note is that PVC and PET are not suitable for pyrolyzing.

Apart from oil, we can also obtain carbon black and some combustible gas, which all have multiple uses.

1) Fuel oil

The fuel oil has a high calorific value of about 44 MJ/kg, which can be used as liquid fuels for industrial furnaces, power plants and boilers. And the oil has a relatively low ash content and residual carbon. If you want to improve the quality and broaden the uses of the fuel oil, DOING also has another machine- waste oil distillation machine to help you refine fuel oil to diesel, which can be used in heavy machines, boilers, generators, etc.

Fuel oil and diesel applications

Fuel oil and diesel applications

2) Carbon black

Carbon black has a calorific value comparable to high-grade coal; therefore, it can be used as fuel either in pulverized or briquetted form.

3) Combustible gas

Apart from heating the pyrolysis machine reactor directly, the combustible can also be used as other heating uses or generating electricity.

DOING has cooperated with thousands of customers about waste plastic pyrolysis machines to recycle plastic into oil and has abundant manufacturing and installation experience, if you are interested in plastic recycling or want to carry out similar pyrolysis projects, welcome for consultation!

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.