Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

Bulk waste plastics

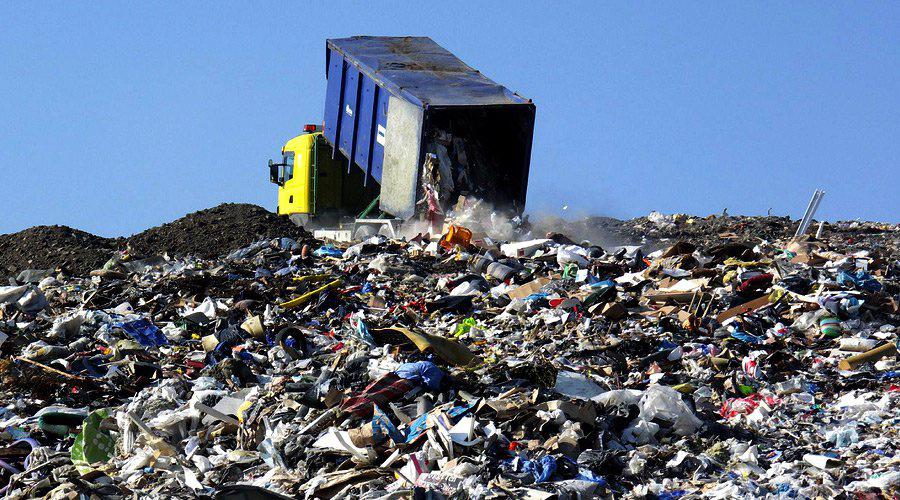

With the increasing consumption of plastic products, waste plastics are also increasing. At present, China's waste plastics are mainly plastic films, plastic wires and woven products, foam plastics, plastic packaging box and vessel plastic products for daily use, plastic bags and agricultural plastic mulching film. Moreover, the annual consumption of automotive plastics in China has reached 400,000 tons, and the annual consumption of plastics for electronic appliances and home appliances has reached more than 1 million tons. These products have become one of the important sources of waste plastic after being scrapped. It is understood that in 2011, China's waste plastics production was about 28 million tons, in 2012 it was 34.13 million tons. The storage, transportation, and processing of these waste plastics are not suitable for the application and post-processing of discarded plastic raw materials that will be processed, and will certainly damage the environment and endanger the health of the people.

Traditional waste plastic solutions and disadvantages

At present, landfill, incineration and direct reclamation and granulation are mainly adopted in the recycling of waste plastics.

1. Landfill.

The plastic landfill solution is a negative and simple method of disposal. which is to bury waste packaging plastic into the waste land or concave field of suburb and make it die out. However, ordinary plastics will disintegrate and disappear within a few hundred years. Therefore, this kind of waste plastic solution is economically simple, but it is the most unsatisfactory for reducing the environmental load.

2. Incineration.

Waste plastic incineration

The incineration process uses a mixture of mixed plastics and other waste materials that cannot be recycled as the fuel, which is burned in an incinerator and then fully use the heat generated by the combustion. The most important feature of this waste plastic solution is to convert what is actually waste into energy, and at the same time, it has an obvious effect on volume reduction. The residue after combustion has a small volume and a high density. It occupies a very small area when it is landfilled. It is also very convenient. At the same time, it is stable and easily dissolved in the soil.

However, the waste plastic incineration solution has the following deficiencies: The investment in incineration equipment construction is large and the cost is high; If indiscriminately incinerated, some plastics inevitably produce secondary pollutants in the incineration process, such as SO2, HC1, HCN, etc, and the residual heavy metals and harmful substances remain in the remaining ash, which will cause damage to the ecological environment and human health.

3. Direct regeneration recycling.

Waste plastic direct regeneration recycling

Direct regeneration recycling mainly refers to direct plasticization of waste plastics after pretreatment, followed by molding or granulation. In some cases, it is necessary to add a certain amount of new resins or suitable compounding agents (such as antioxidants, lubricants, stabilizers, and colorant, etc.) and made into the recycled plastic products. It can adopt the modern technology and equipment, which is economic and efficient.

The general process of this waste plastic solution is: Pretreatment (sorting, cleaning, defoaming, etc.)→ crushing → washing and stirring → mixing and homogenizing → plasticization → granulation or remanufacturing.

However, due to the labor-intensive, high costs of recycling, and secondary pollution during the granulation process, and the lack of recycling channels, the world recycling granulation and reuse only account for about 15% of the total plastic consumption. But because of the limited oil resource of the world. It is of great significance that the recycling of plastic from the perspective of saving the earth's resources. Therefore, all countries in the world have invested a lot of manpower and material resources to develop various key technologies for the recycling of waste plastics, and have devoted themselves to the development of suitable applications for reducing the cost of recycling plastics.

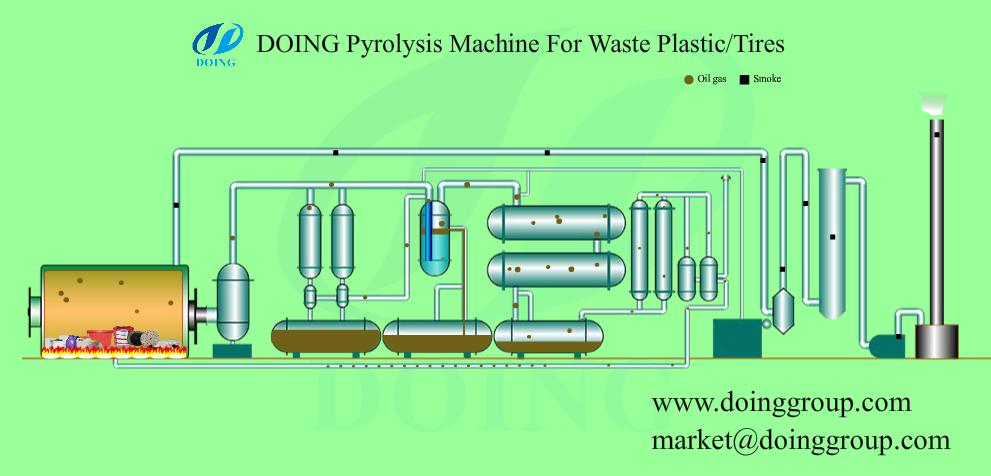

New Type Waste Plastic Solution--Pyrolysis Technology

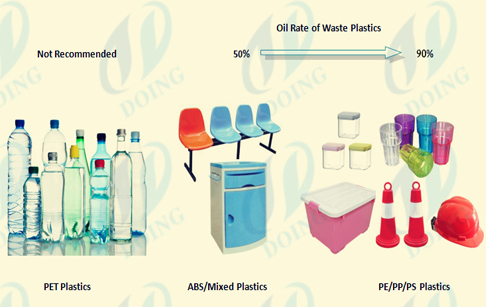

At present, many developed countries regard the production of high-value chemical products from the plastic pyrolysis plant as the main point of technological development. It doesn’t have to sort waste plastic strictly at the time of pyrolysis processing and simplify the pretreatment process, especially suitable for the processing of mixed plastic. This waste plastic solution can not only purify the environment, but also develop new energy, make waste plastics a valuable industrial raw material, realize material recycling, and increase economic efficiency. It is a promising development project.

“Pyrolysis” refers to the process of molecular breakdown the low molecules industrial gases, fuel oils, and cokes in a reducing gas and at high temperatures. The whole pyrolysis process occurs in a closed device, which is safe, odorless and pollution-free. And plastics pyrolysis results in greatest production of fuel oil and syngas at high calorific values, which is a key element of efficient waste to energy process aimed at the production of electricity, steam or heat.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.