Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Product

Project Case

-

DOING® Group|100 TPD Continuous Tire Pyrolysis Plants Installed for Repeat Client in China

-

Customized 1 Ton/Day Continuous Plastic Pyrolysis System Delivered for Korean Client

-

DOING DY-15 Waste Tire Pyrolysis Machine Project Successfully Installed in Kenya

-

DOING 45,000 Tons/Year Waste Plastic Pyrolysis Project in Vietnam Successfully Commissioned

-

DOING Tire & Plastic Pyrolysis Distillation Plant Successfully Installed in Fiji

-

DOING 50TPD Continuous Oil Sludge Pyrolysis Production Line Successfully Installed in China

-

DOING Installed 15-Ton Tank Bottom Sludge Pyrolysis Equipment for Colombian Repeat Client

-

DOING 30TPD Mazut Oil Distillation Plant Successfully Installed in Kazakhstan

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

How does the fully continuous waste tire pyrolysis plant produce fuel oil?

2022-08-23 / Continuous Pyrolysis plant / Leave Message / Chat Online

With the increase in processing capacity, many people want to use fully continuous pyrolysis plants to recycle waste tires and produce fuel oil, which can greatly improve production efficiency and reduce labor costs. So how does the fully continuous waste tire pyrolysis plant produce fuel oil? Next, I will introduce it to you.

DOING factory fully continuous waste tyres pyrolysis plant

DOING factory fully continuous waste tyres pyrolysis plant

1. Tire pretreatment

Since the fully continuous waste tire pyrolysis plant needs to realize continuous feeding, the raw material requirements are also relatively high. Before feeding, we need to pull out the steel wire inside the tire and crush the tire into fine rubber powder.

2. Feeding&heating

The fully continuous waste tire pyrolysis plant uses a screw-sealed feed auger to feed the rubber powder into the reactor. The feeding speed of the feeder can be set to control the whole process in an orderly manner. Continuously heat the pyrolysis reactor, and the rubber powder can completely be pyrolyzed and the oil gas comes out.

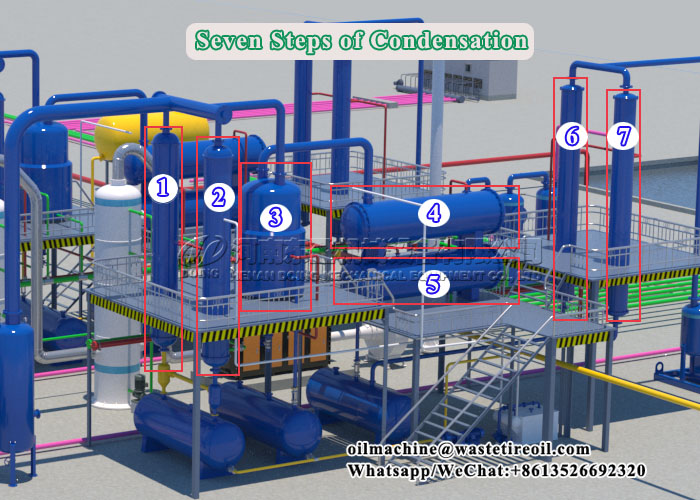

3. Cooling system

DOING's fully continuous waste tire pyrolysis plant uses the latest condensation technology and sets up four condensers to completely cool the oil gas into liquid oil, which can guarantee the high oil yield of the waste tire pyrolysis. The obtained liquid oil is temporarily stored in the fuel tank that comes with the fully continuous waste tire pyrolysis plant. Finally, when the oil tank is full, all the obtained oil is automatically pumped into the large tank.

Cooling system

Cooling system

4. Slag discharge

We designed the carbon black discharge system to connect the slag discharge at the end of the reactor. And the whole discharge system is totally sealed and no dust, which can continuously discharge carbon black, making the tire pyrolysis plant more effective.

Carbon black discharge system

Carbon black discharge system

Above is the main working process of fully continuous waste tire pyrolysis plant to produce fuel oil. DOING fully continuous waste tire pyrolysis plant is almost completely automated and intelligent, saving labor cost and reducing human errors.

Henan DOING Company has been engaged in the fully continuous pyrolysis plant R&D for 11+ years. We have mature technology and rich practical experience in many countries, such as Kazakhstan, Spain, Brazil, Russia, etc. If you are facing the problem of large amounts of tire disposal and wanna make great profits, please contact us without hesitation. Doing Company will provide you with the best solution of fully continuous waste tire pyrolysis plant.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.