Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Product

Project Case

-

DOING® Group|100 TPD Continuous Tire Pyrolysis Plants Installed for Repeat Client in China

-

Customized 1 Ton/Day Continuous Plastic Pyrolysis System Delivered for Korean Client

-

DOING DY-15 Waste Tire Pyrolysis Machine Project Successfully Installed in Kenya

-

DOING 45,000 Tons/Year Waste Plastic Pyrolysis Project in Vietnam Successfully Commissioned

-

DOING Tire & Plastic Pyrolysis Distillation Plant Successfully Installed in Fiji

-

DOING 50TPD Continuous Oil Sludge Pyrolysis Production Line Successfully Installed in China

-

DOING Installed 15-Ton Tank Bottom Sludge Pyrolysis Equipment for Colombian Repeat Client

-

DOING 30TPD Mazut Oil Distillation Plant Successfully Installed in Kazakhstan

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

What’s the waste tyre continuous pyrolysis process ? How does pyrolysis work?

2018-11-13 / Continuous Pyrolysis plant / Leave Message / Chat Online

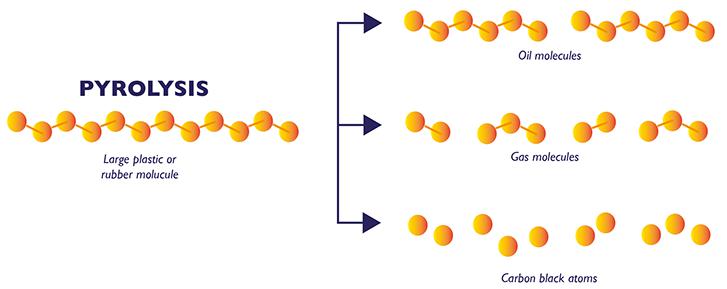

How does pyrolysis work?

The formula of the pyrolysis process is as below:

(-CH2-CH2-)n → n[C+H2+CH4+C2H6+C3H8+C4H10+…+C11H24+…C20H42+…]

(Remark: C5H12~C11H24 is gasoline fraction, C12H26~C20H42 is diesel fraction, C20 above is heavy oil fraction).

Pyrolysis technology

Pyrolysis technology

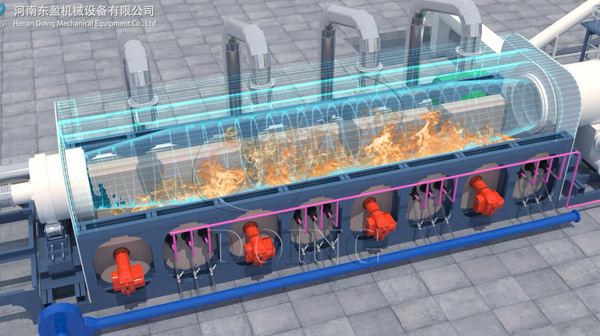

Normally, the operation temperature of the waste tyre pyrolysis process is about 200-450℃. DOING’s pyrolysis reactor adopts heating from outside with sealed design, thus to keep no gas leak out, not only increase the pyrolysis efficiency, but also eliminate the potential risk of safety problem and pollution.

What’s tyre pyrolysis process?

tyre is mainly composed of rubber (include natural rubber and synthetic rubber), carbon black and many other organic and inorganic addition agents (include plasticizer, antiager, sulphur , zinc oxide, etc). Waste tyre pyrolysis means the process that under a sealed furnace with proper heating, the main chain of the rubber in tyres cracked into monomer, biopolymer and fragments, which then be polymerized to many kinds of olefins, thus get rid of the volatile substances to solid carbon. The main end products are fuel oil, pyrolysis gas, carbon black and steel wire. The composition of every product is different as different pyrolysis methods, temperature, etc.

Tyre pyrolysis reactor

Tyre pyrolysis reactor

Through tyre pyrolysis process, it could recycle waste tyres to renewable energy, also without generating secondary pollution to the environment. And DONG Company’s new type continuous waste tyre pyrolysis plants are all equipped with smoke cleaning system, tail gas cleaning system, bad smell removal system and water circulation system, thus to keep no pollution to both the air and water.

Continuous waste tyre pyrolysis plant

Continuous waste tyre pyrolysis plant

As the waste tyre amount is generated higher and higher, the waste tyre pollution is also becoming heavier and heavier. So, it’s very urgent and important for the world to find a way how to dispose the waste tyres , thus to prevent or reduce the pollution caused by waste tyres.

Waste tyres

Waste tyres

So far, to dispose waste tyres, there are mainly the following methods:

1) Pile up to landfill;

2) Recycle heat by burning and incineration;

3) tyre retreading;

4) Waste tyre recycling to reclaimed rubber.

If you made some research about the waste tyre recycling, you should know that the processing ways cause big waste of the raw material, also generate heavy pollution to the environment. In view of this current situation, we recommend you the pyrolysis process as a new and clean solution to recycle the waste tyres.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.