Home > Product > Waste Oil Recycling to Diesel Plant > Waste plastic to diesel and gasoline process plant

Philippines customer bought 10T

Contact Us

Waste plastic to diesel and gasoline process plant

Through 2 year research and study, we developed a new technology to combine the pyrolysis and distillation in the same pr...

Skype:bonniezhao2

+86-135-2669-2320

+86-371-56771821

WhatsApp:0086 135 2669 2320

- Features:

- Technical Data:

- Application:

Waste Plastic Pollution

Waste plastic pollution

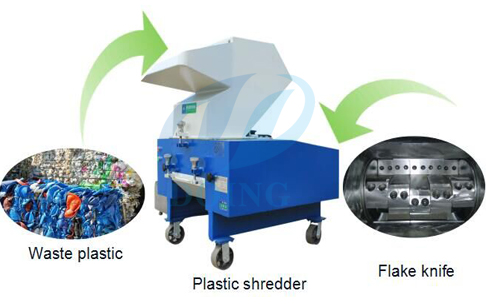

As the speed development of plastic industries, the application of plastic products has been becoming wider and wider. The wide application of the plastic products bring many convenience to people’s life, but in the same time, it causes problems. As we all know that plastics are very difficult to decompose in the natural environment, thus more and more plastic waste generate serious environment pollution.

Treatment – Pyrolysis and Distillation

Plastic pyrolysis plant

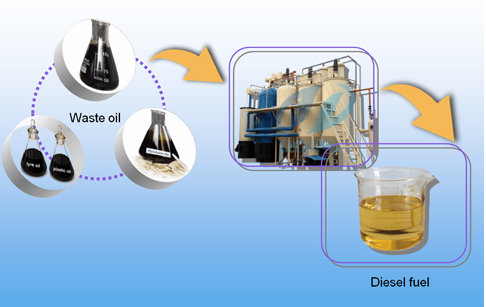

Waste oil to diesel plant

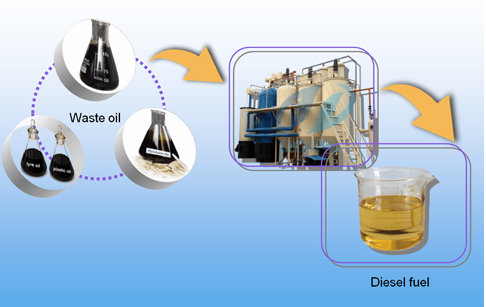

At present, the main way to dispose the waste plastics is burn or landfill. But we all know that no matter burn or landfill, it causes secondary pollution to the environment. Thus a green and environmental protection way to dispose the waste plastics is very necessary. That’s why the plastic to oil technology was developed and is becoming more and more popular. Plastic to oil technology is a way to get renewable energy from plastics without generating secondary pollution to the environment. Through this technology, you could get fuel oil and carbon black (biochar) from waste plastics by pyrolysis process. By selling the fuel oil and carbon black products recycled from waste plastics, it brings high benefit to the user, also reduces the landfill and environment pressure. In addition, if someone want to get diesel product, the plastic pyrolysis oil product also could be further processed to diesel by a distillation process. For most beginners, pyrolysis and distillation are already very enough for them to dispose the waste plastics. But for some high-demanding specialized or government projects, this normal pyrolysis and distillation process is not enough for them.

New Technology

Waste plastic to diesel and gasoline process plant

Through 2 year research and study, we developed a new technology to combine the pyrolysis and distillation in the same process, also with fractionation. The machine name is waste plastic to diesel and gasoline process plant,Through this waste plastic to diesel and gasoline process plant, you could get diesel, gasoline and heavy oil separately in the same time.

Waste plastic pollution

Treatment – Pyrolysis and Distillation

Plastic pyrolysis plant

Waste oil to diesel plant

At present, the main way to dispose the waste plastics is burn or landfill. But we all know that no matter burn or landfill, it causes secondary pollution to the environment. Thus a green and environmental protection way to dispose the waste plastics is very necessary. That’s why the plastic to oil technology was developed and is becoming more and more popular. Plastic to oil technology is a way to get renewable energy from plastics without generating secondary pollution to the environment. Through this technology, you could get fuel oil and carbon black (biochar) from waste plastics by pyrolysis process. By selling the fuel oil and carbon black products recycled from waste plastics, it brings high benefit to the user, also reduces the landfill and environment pressure. In addition, if someone want to get diesel product, the plastic pyrolysis oil product also could be further processed to diesel by a distillation process. For most beginners, pyrolysis and distillation are already very enough for them to dispose the waste plastics. But for some high-demanding specialized or government projects, this normal pyrolysis and distillation process is not enough for them.

New Technology

Waste plastic to diesel and gasoline process plant