The latest waste tyre and plastic recycling plant

Features of waste tyre and plastic recycling plant as follows:

1. raw material is cheap and easy to provide

2. 100% wastage tyre recycling is achieved

3. no soil, water or air pollution is observed during and after the process

4. creates economically valuable products out of wastage tyres

5. cost-effective wastage tyre recycling technology in the world

6. it is a 100 % pollution free process, thus making eco-friendly environment

7. the process can be applied to all rubber based materials

8. the system creates an alternate source of energy to replace petroleum products and natural gas

9. system gives the opportunity to governments and local administrations to deal with the wastage tyre problem

10. The process of pyrolysis has duration of 15 to 18 hours, depending on the quantity and size of tyre. During the process different vacuum values are applied in pre-determined temperatures in different phases. Different gases are obtained and the condensed gas is stored as a fuel oil in tank.

As a result of pyrolysis of waste tyres, we obtain:

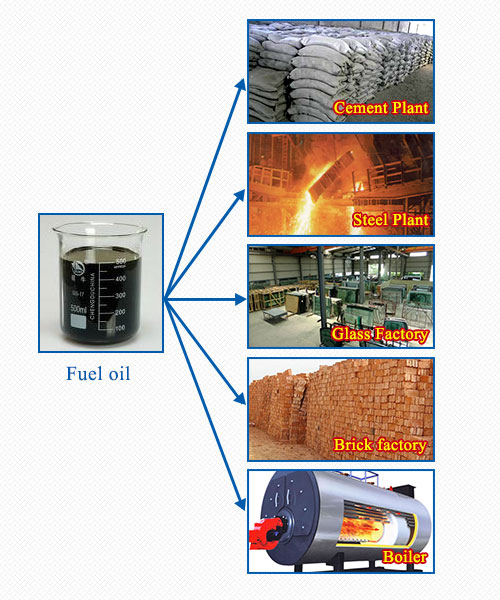

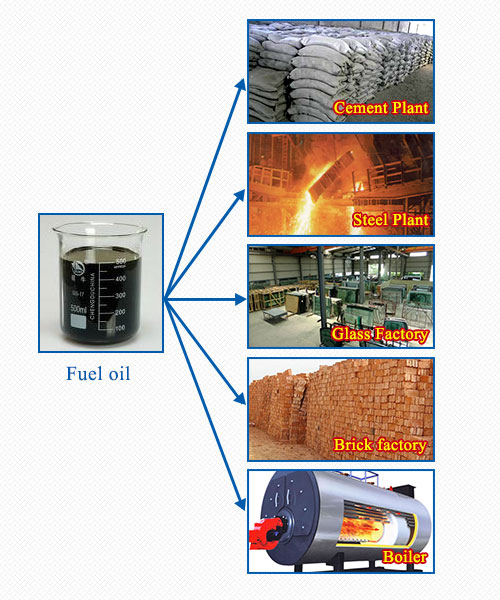

1. Fuel oil (40% to 45%)

Through our recycling machine, we obtain fuel oil, which is extensively used for industrial and commercial purposes. The oil has 45% to 55% of the amount of recycled scrap tyres, which are carried with licensed tanker trucks.

2. Carbon black (30% t0 35%)

Carbon black is the main product recycled by pyrolysis process. The amount of recycled carbon black is 30% to 35% (depending on the type of tyres) of the total amount of scrap tyres recycled in the system. Carbon black is used as raw material or as the main ingredient in many industries. The chemical structure of carbon black strengthens, lengthens and improves the coloring features of the materials.

Carbon black produced by pyrolysis process (cbp) is more economical as compared to carbon black produced primarily from petroleum. It is more reasonable to be used as an ingredient in the industries listed mentioned below:

• electric cable jacketing

• conveyor band

• carrier bands

• hose and doormat

• black nylon bag

• rubber additive

• automotive spare parts

• heat isolation

• black colorant in rubber materials

• plastic pipes

• industrial rubber products

• fire fighting

|

Technical parameter of the latest waste tyre and plastic recycling plant |

|

No. |

Items |

Contents |

|

1 |

Equipment type |

DY-1-6 |

DY-1-8 |

DY-1-10 |

|

2 |

Raw material |

Waste tyre/plastic |

Waste tyre/plastic |

Waste tyre/plastic |

|

3 |

Structural form |

Horizontal rotation |

Horizontal rotation |

Horizontal rotation |

|

4 |

24-hour Capacity |

6 ton |

8 ton |

10 ton |

|

5 |

Oil yield |

2.7-3.3ton |

3.6 -4.4ton |

4.5 -5.5ton |

|

6 |

Operating pressure |

Normal |

Normal |

Normal |

|

7 |

Material of pyrolysis Reactor |

Q245R |

Q245R |

Q245R |

|

8 |

Thickness of pyrolysis Reactor |

16mm |

16mm |

16mm |

|

9 |

Rotate speed of pyrolysis Reactor |

0.4turn/minute |

0.4turn/minute |

0.4turn/minute |

|

10 |

Total power |

19KW |

19KW |

19KW |

|

11 |

Mode of cooling |

Water cooling |

Water cooling |

Water cooling |

|

12 |

Cooling area of condenser |

100sqm |

100sqm |

100sqm |

|

13 |

Kind of transmission |

Internal gear drive |

Internal gear drive |

Internal gear drive |

|

14 |

Noise dB(A) |

≤85 |

≤85 |

≤85 |

|

15 |

Size of Reactor(D×L) |

2200×6000 |

2200×6600 |

2600×6600 |

|

16 |

Working form |

Intermittent operation |

Intermittent operation |

Intermittent operation |

|

17 |

Delivery time |

20days |

20days |

20days |

|

18 |

Weight |

27T |

30T |

35T |

|

Prepared by customer about the latest waste tyre and plastic recycling plant |

|

No. |

Item |

Consumption |

|

1 |

Coal(for choice) |

500kg/day |

|

2 |

Wood(for choice) |

800kg/day |

|

3 |

Natural gas(for choice) |

100-150kg/day |

|

4 |

Oil(for choice) |

300-350kg/day |

|

5 |

Electricity |

244kwh/day |

|

6 |

Water(recycled) |

60㎥ /month |

|

7 |

Total power |

19kw |

|

8 |

Land area |

35m*15m |

Fuel oil application from waste tyre and plastic recycling plant

Our clients can avail from us premium quality waste tyre and plastic recycling plant that is manufactured employing latest equipment at vendors' end. It scores high on functional life and also exhibits durability and reliability. In addition to this, it is packed using tamper-proof and strong material to facilitate its safe transit.

On offer from us is world class range of Waste tyre and plastic recycling plant that is procured from the vendors of high repute after doing extensive market research. It is known for its high quality, excellent performance and low power consumption. Apart from this, we make sure that these products are delivered within postulated time frame at clients' premises.