Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

FAQ

-

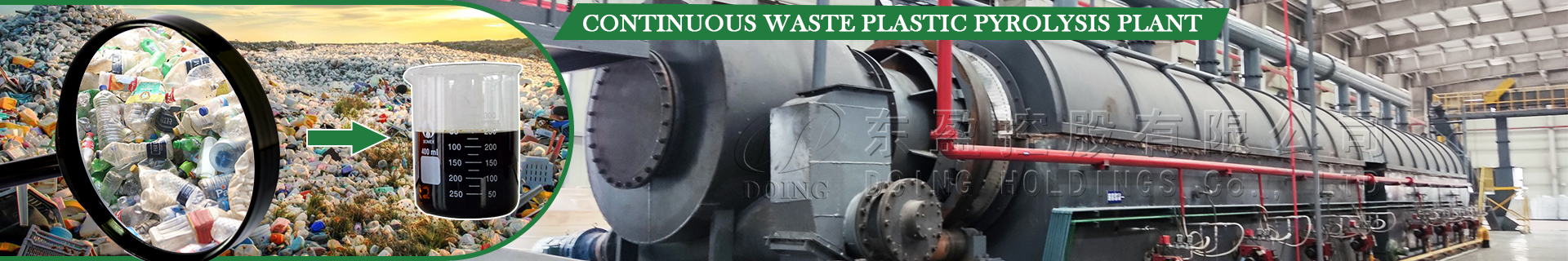

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Continuous plastic pyrolysis plant

Our continuous plastic pyrolysis plant can continuously processes plastic into crude oil and carbon black without stoppi...

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

- Features:

- Technical Data:

- Application:

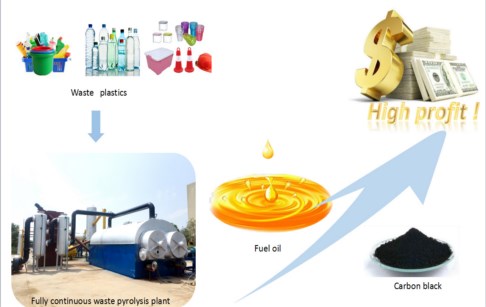

Waste plastic

The global recycled plastic & plastic waste to oil market has been broadly segmented on the basis of plastic type into polyethylene (PE), polyethylene terephthalate (PET), polystyrene (PS), polyvinyl chloride (PVC), polypropylene (PP), and other plastics (acrylic, polycarbonate, polylactic fibers, nylon, and fiberglass). On the basis of technology, the global recycled plastic & plastic waste to oil market has been segmented into pyrolysis, gasification and synthesis, and catalytic depolymerization processes. The global recycled plastic & plastic waste to oil market has also been segmented on the basis on end-fuel into diesel, gasoline, kerosene, synthetic gases, and others.

We, Henan Doing Mechanical Equipment Co., Ltd is a leading manufacturer specialized in waste tire /plastic/rubber pyrolysis plant has developed highly efficient continuous plastic pyrolysis plant.

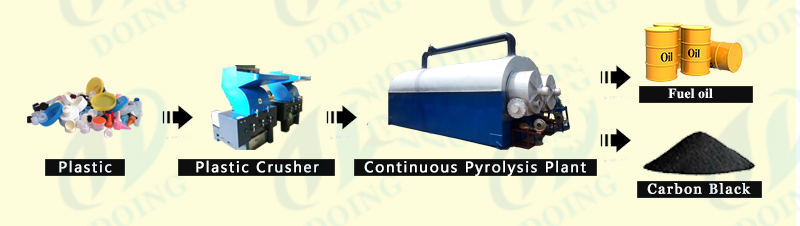

Here is a process picture for you to understand:

All available plastic can be shredded by plastic crusher, and then plastic granules can be fed directly into continuous plastic pyrolysis plant through the feeding door. Our feeding door has screw inside, so it can help you easily convey the plastic granules into our reactor No 1, then all the waste plastic can be fully decomposed under the high temperature through reactor No 1 to reactor No 2,then to reactor No 3...Until all the plastic fully pyrolysed, then all the carbon black powder will be discharged automatically to the carbon black tank.

All the available oil gas will be cooled by circulation water and the extra pyrolysis gas will be recycled through pipes into the burners for heating again. In our continuous plastic pyrolysis plant, the water circulation system and extra pyrolysis gas recycling system will help you save much fuel and water resource. In this way, our continuous plastic pyrolysis plant can minimize your cost and maximize your profits.

Through our continuous plastic pyrolysis plant, you will convert waste plastic into fuel oil and carbon black easily and automatically. If you need more information and help, welcome to contact us at any time.

Continuous plastic pyrolysis plant picture show

Picture show of continuous plastic pyrolysis plant

- Features:

- Technical Data:

- Application:

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

- Features:

- Technical Data:

- Application:

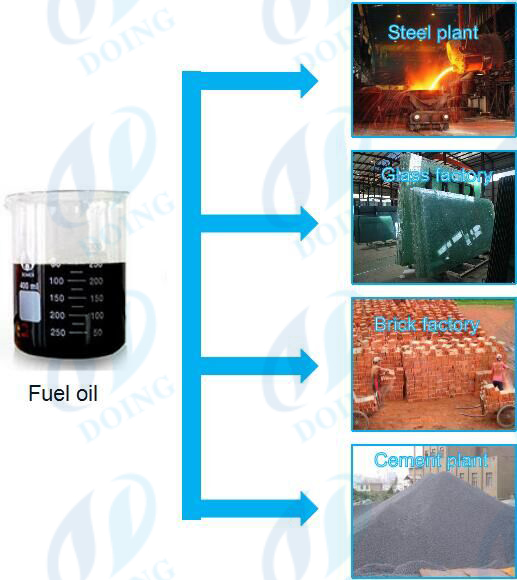

1. Fuel oil (45%-52%): Oil from continuou plastic pyrolysis plant can be used as industrial fuel for burning.The fuel oil application :Such as power plant factory,glass factory,cement factory,boiler factory.

Fuel oil application

Carbon black application

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.