Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

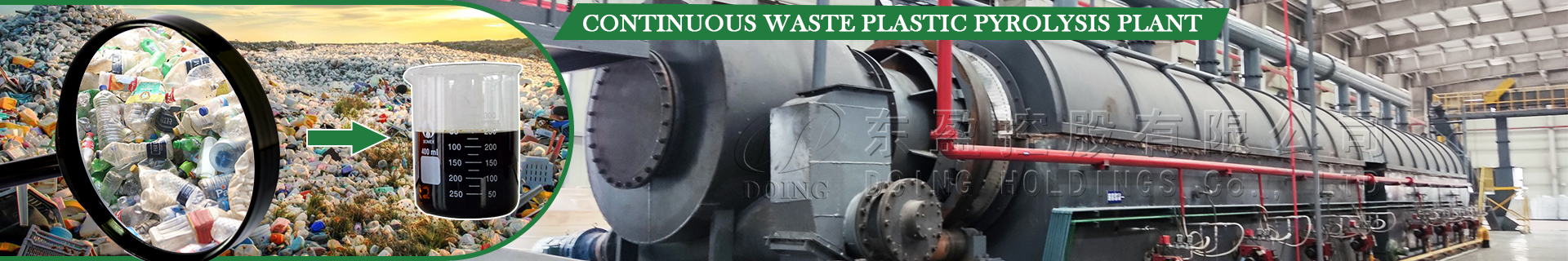

Continuous waste plastic pyrolysis plant

The appearance of continuous waste plastic pyrolysis plant produced by Doing Group can not only solve the plastic pollu...

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

- Features:

- Technical Data:

- Application:

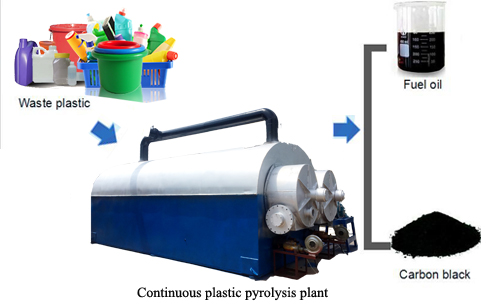

Waste plastics

Continuous waste plastic pyrolysis plant

Till now, our continuous waste plastic pyrolysis plant has be exported to more than 30 countires, such as Egypt, Malaysia, Mexico, Italy, Romania, Ecuador, Haiti, Thailand etc.

Pyrolysis plant install in different countries

Continuous waste plastic pyrolysis plant

We have some safe devices such as the pressure gauge, alarming ring, safety valve. at the same time we have the anti-back fire device which can avoid the fire back into the reactor.

2. Environment protecting.

If you come to visit our company to see the running plant, you cannot even see the vapor. as we have the dust removal device and dust removal pool.

3. Energy saving.

Our anti-back fire device can collect the exhaust gases which can be fuels after the oil is out so is very convenient and you can save the energy .at the same time, we have the catalyst

chamber which can reduce the temperature of the catalytic prolysis of the tires and plastics. so you can save lot's of energy. except this ,we have vacuum device which let the reactor be negative pressure. So you can image.

4. High degree of automatic.

We have many automatically devices such as: auto-feeder, carbon black elevator, oil pumping automatic, reducing pressure automatic.

- Features:

- Technical Data:

- Application:

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

- Features:

- Technical Data:

- Application:

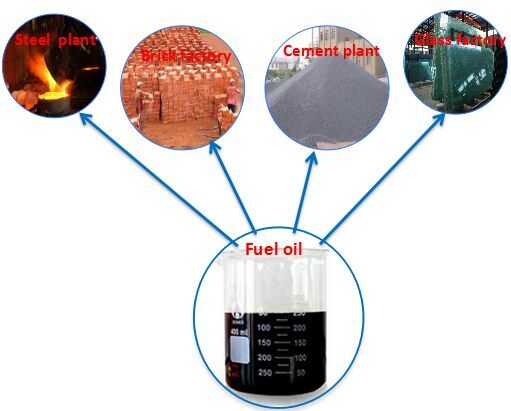

C.cement factory

D.ceramic fatory

E.aluminum factory

F.boiler factory

G.central heating factory

H.painting factory

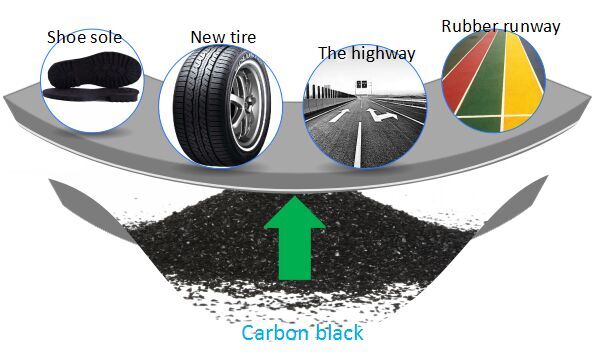

B.conveyor ban

C.hose and doormat

D.black nylon bag

E.rubber additive

F.automatic spare partsG.heat isolation

H.black colorant in rubber materials

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.