Philippines customer bought 10T

Contact Us

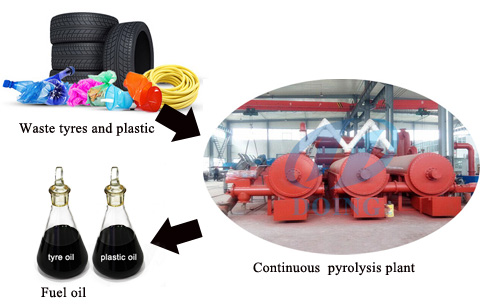

How to work the continuous waste tyre pyrolysis plant?

2017-01-04 13:51

Continuous waste tyre pyrolysis plant

The continuous waste tyre pyrolysis plant is equipped with automatic feeding and discharging system, which can realize feeding materials on one side and discharging the slag continuously from the other side. It not only can dispose 30-50 tons waste tyres per day but also can work continuously for 24 hours without a stop.

Continuous waste tyre pyrolysis plant working process

2. Remove steel wire: Use a steel wire pulling machine to pull out the steel wire from waste tyres. The steel wire pulling machine is operated automatically, which only need one work for operation.

3. Shred tyres: Use a specialized tyre shredder to process big whole tyres into 3-5cm small pieces for easy feeding. The tyre shredder is a single and fully automatic shredding system, which can be directly connected to the feeding system of the continuous pyrolysis plant, which no need any transfer process.

4. Continuous pyrolysis process: Shredded tyres go into the continuous waste tyre pyrolysis plant, will firstly go through a mutiple pyrolysis reactor system to be pyrolyzed into oil gas. And oil gas will be cooling down to liquid oil through the cooling system. The residues (carbon black) will be pushed by continuous feeding tyres to the carbon black dischrge system for discharge.

Leave a Message