Waste aluminum plastic composite panel separation machine

Waste aluminum plastic composite panel separation machine

Waste aluminum plastic composite panel separation machine is combined with the domestic and international advanced technology was developed.

The aluminum plastic composite panel separation machine adopts the advanced physics law recovery processes; The developed crusher and high pressure electrostatic separation equipment innovation is strong, the recycling of the process route is advanced and reasonable. The aluminum plastic composite panel separation machine can be used for all kinds of circuit boards, computer board, TV board, aluminum-plastic plate, with copper, printed circuit board and the processing waste, such as waste electrical appliance for mechanical crushing recycling, the metal recovery rate is high, the recovery of 98% purity metal.

Waste aluminum plastic composite panel separation machine technical data

|

Item |

Model |

Capacity(kg/h) |

Power(Kw) |

Size (m)(L*W*H) |

Weight(T) |

Remark |

|

1 |

DY-400 |

150-200 |

35 |

3.8×1.5×3.0 |

1.8 |

|

|

2 |

DY-500 |

300-500 |

65 |

4.2×1.7×3.0 |

3.0 |

|

|

3 |

DY-800 |

500-800 |

90 |

4.5×1.5×4.2 |

7.7 |

|

|

4 |

DY-1000 |

800-1000 |

120 |

4.8×1.8×4.2 |

9.4 |

|

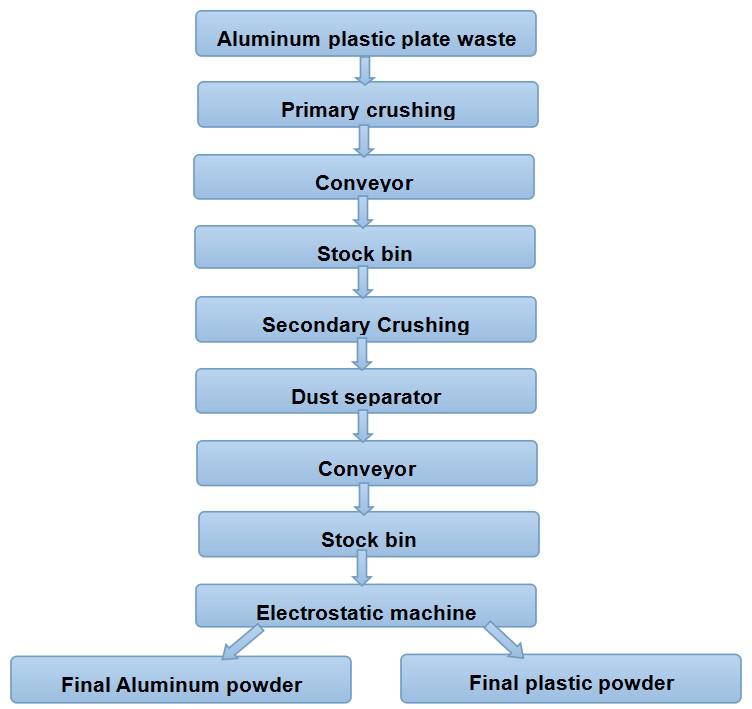

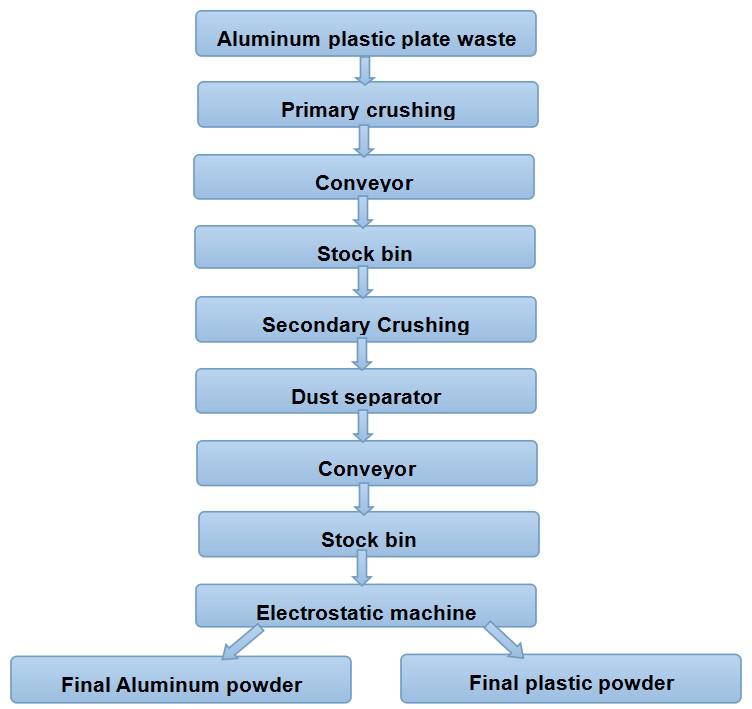

Waste aluminum plastic composite panel separation machine work steps

Waste aluminum plastic composite panel separation machine work steps

When the waste aluminum plastic composite panel separation machine was sent into the aluminum plastic composite panel separation machine, they will use the aluminum separator to directly produce, aluminum and plastic can be completely separated. The recovery aluminum can be used to smelting the aluminum ingots and also are the upper materials.