Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

News

-

DOING News

-

Industry News

Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

China 50-Ton Continuous Pyrolysis Machine Order for Waste Tire Recycling

2025-01-24 / DOING News / Leave Message / Chat Online

In January 2025, Doing Group successfully signed a contract with a Chinese client for a 50-ton continuous pyrolysis machine, marking another green cooperation in our commitment to offer sustainable waste tire management and recycling solutions.

The client, a well-established tire recycling trader with two overseas tire shredding plants, aimed to enhance their recycling efficiency and profits by converting shredded rubber powder into fuel oil.

Waste tire to rubber powder shredding production line

Waste tire to rubber powder shredding production line

Choosing Doing Group as their partner was a strategic decision. As a renowned supplier in China, Doing Group has a proven track record of delivering high-quality pyrolysis machine with over a decade of experience in the industry. Our continuous pyrolysis machines are designed for large-scale operations, ensuring high efficiency, low energy consumption, and easy maintenance.

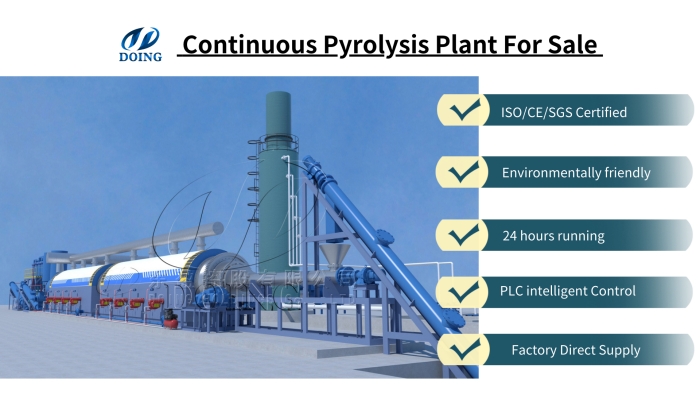

Our continuous pyrolysis machine is equipped with state-of-the-art features, including automated feeding and discharge systems, high-efficiency condensation, and advanced dust removal technology. These innovations not only enhance operational efficiency but also guarantee high-quality fuel oil production.

Continuous rubber powder recycling pyrolysis plant

Continuous rubber powder recycling pyrolysis plant

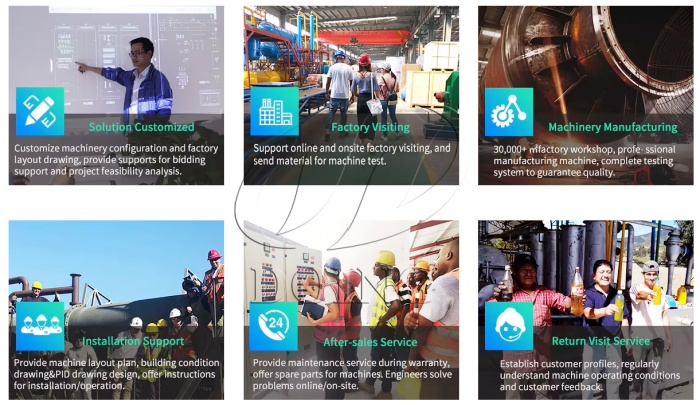

The waste rubber powder pyrolysis project's cooperation was not only due to our advanced continuous tire pyrolysis technology but also to our comprehensive service approach. From initial communication to project implementation, which took nearly a year to complete, our team of engineers and project managers provided dedicated support. We assisted the client in developing a tailored technical solution and navigated the complex process of environmental approval. Our commitment to environmental sustainability is evident in our equipment's ability to meet strict emission standards, ensuring minimal environmental impact.

China DOING continuous pyrolysis machine manufacturer services

China DOING continuous pyrolysis machine manufacturer services

This Chinese client's satisfaction with our continuous rubber powder pyrolysis machine and services reflects our dedication and excellence to delivering reliable and sustainable solutions. For those seeking to enhance their waste tire recycling operations, please contact Doing Group for getting a complete package of solutions, from equipment supply to project building and environmental compliance.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.