Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

News

-

DOING News

-

Industry News

Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

Russian customers ordered a 50TPD full continuous waste tire pyrolysis plant from Doing Company

2022-04-16 / DOING News / Leave Message / Chat Online

On April 15, 2022, Henan Doing Company received the equipment deposits from Russian customers, who successfully ordered a set of 50TPD full continuous waste tire pyrolysis plant from DOING.

It only took nearly two months from when Doing Company received the inquiry from the Russian customers to when the customer decided to sign a contract with us to purchase equipment. Why do our Russian customers trust the purchase of 50TPD full continuous waste tire pyrolysis plant from DOING? Undoubtedly, this is actually inseparable from the strong strength of Doing Company, the mature technology of full continuous waste tire pyrolysis plant, and the professional services provided by sales managers and engineers.

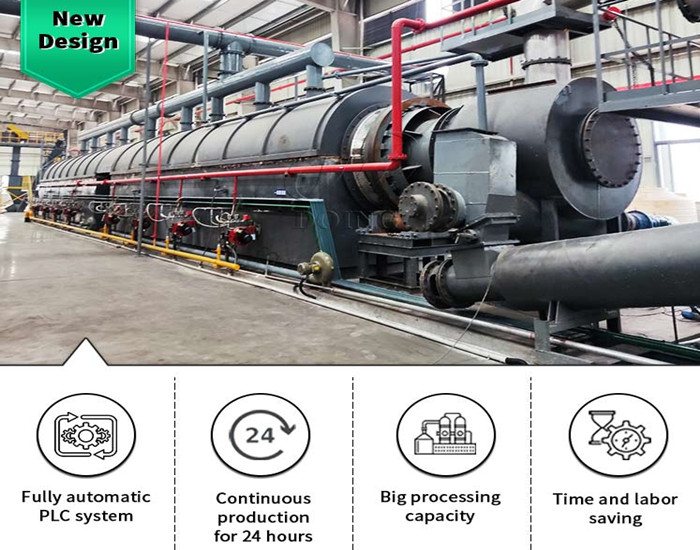

DOING new design fully continuous pyrolysis plant

DOING new design fully continuous pyrolysis plant

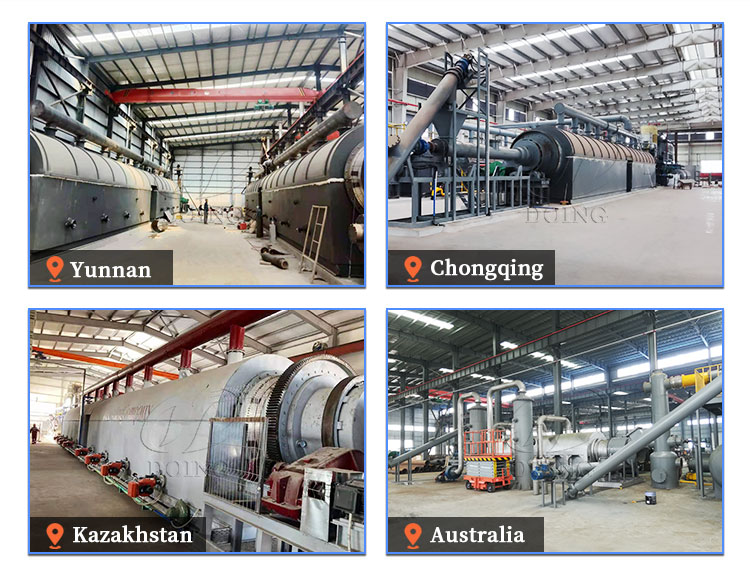

When communicating with us, the Russian customers mentioned that they decided to contact us after they carefully checked the official website of Doing Company and learned that our company has installed equipment projects in more than 90 countries and regions as the direct manufacturer and supplier. Since they were engaged in the petroleum processing industry, the Russian customers were very concerned about the yield and quality of pyrolysis fuel oil, the automation degree and environmental protection of waste tire pyrolysis plant.

Some fully contiuous waste tyre pyrolysis plant project cases of DOING company

Some fully contiuous waste tyre pyrolysis plant project cases of DOING company

Combined with the customer's specific processing capacity requirements, our project manager delicately formulated a 50TPD full continuous waste tire equipment purchase plan, and introduced the designs and pyrolysis technology of our pyrolysis plant for the customer. And we have the independent manufacturing factory and technical team, so all machines can be customized at the most favorable factory price. Besides that, our engineer team also customized the waste tire pyrolysis plant area planning and drawing for Russian customers. Therefore, the full range of technical support and production solutions provided by Doing Company made Russian customers feel very trusted. They readily reached a cooperation with us and ordered 50TPD full continuous waste tire pyrolysis plant.

Advantages of DOING company

Advantages of DOING company

Offering the best machines and services to our customers is what Doing Company is always doing! If you are interested in developing the waste tire/plastic to diesel recycling business, welcome to contact Doing Company for professional solutions and customize the best waste tire/plastic pyrolysis plant and the pyrolysis oil to diesel refining plant at a favorable price.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.