Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

News

-

DOING News

-

Industry News

Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

Doing Group Introduces Innovative New Pyrolysis Technologies and Fully Automatic Continuous pyrolysis plant

2016-05-19 / DOING News / Leave Message / Chat Online

Continuous pyrolysis plant

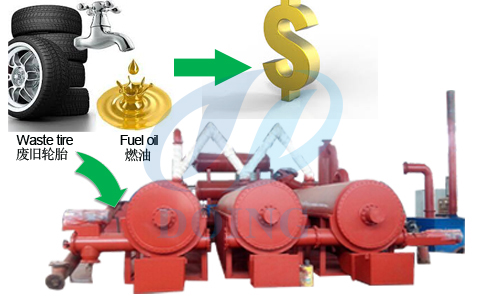

With waste plastic and tire accumulating worldwide, the Doing Group new pyrolysis technologies and equipment offer up effective solutions to some growing problems. Pyrolysis occurs when organic materials, like those based on hydrocarbons, are subject to controlled heat in environments free of oxygen or other catalysts. Making effective use of this well-understood process, a new Reactor System can turn waste like old tires into useful fuel, raw materials like black carbon, and steel.

"Managing plastic and rubber waste has become a challenge all over the world, with limited recycling efforts of conventional kinds barely making a dent in these problems," Doing Group representative engineer said, "We're proud to announce a range of new technologies and systems that are going to make a big difference. No longer will it be necessary to simply bury old tires in landfills, bury or landfills is harmful to land,for example, as our fully automatic continuous pyrolysis plant make it possible to cost-effectively turn them into oil, carbon black, and useful steel."

Familiar to just about everyone in the form of the process that produces charcoal from wood, the transformation known as pyrolysis has been recognized since ancient times. Compared to the outright combustion of organic materials, where the presence of catalyzing agents like oxygen allows for the almost complete breakdown of a substance, pyrolysis is much more controlled. Without oxygen or another halogen to intensify the reaction, substances like plastic and rubber can, through the focused use of pyrolysis, be reduced to constituent materials like oil and carbon.

With nearly 300 million tires being discarded every year in the United States alone, the time is right for the widespread adoption of this approach. The average passenger vehicle tire comprises up to 60% hydrocarbons, locking up for the duration of its lifetime valuable fossil fuels that go to waste when such products are simply buried in landfills.

Doing Group fully atomatic continuous pyrolysis plant not only can solve solid pollution in your country but also can bring much profit to you.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.