Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

News

-

DOING News

-

Industry News

Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

Continuous waste tyre pyrolysis plant price

2018-11-29 / Industry News / Leave Message / Chat Online

The continuous waste tyre pyrolysis plant price is the most important factor that influences the cost of continuous waste tyre pyrolysis plant recycling waste tyre and plastic to oil. If you want to gain more profit with less cost, the continuous waste tyre pyrolysis plant price is what should be paid special attention to. Next, you should know what the other factors affecting the continuous waste tyre pyrolysis plant price.

Continuous waste tyre pyrolysis plant

Continuous waste tyre pyrolysis plant

The first you should decide what is the daily capacity of the continuous pyrolysis plant you want to get. Certainly, different capacity has different price. The most common used capacity is 10T/D and 12T/D, which is enough for most individual customers. For enterprise or government and other customers who have more waste materials to dispose, we DOING also supply continuous pyrolysis plant, with a capacity of 30T/D and automatic control system. Therefore, you should confirm how many tons of waste tires or plastics you can collect per day or how many tons you want process per day.

Waste tyres collected

Waste tyres collected

What’s more, what configuration of the pyrolysis plant you want also decide the price of the pyrolysis plant. Take our DOING’s continuous pyrolysis plant as example, it’s fully equipped with various safety devices, environmental protection system, as well as different types of cooling system with different reactor design, which you could choose the configuration you like and confirm the price.

Tconfiguration of the continuous pyrolysis plant

Tconfiguration of the continuous pyrolysis plant

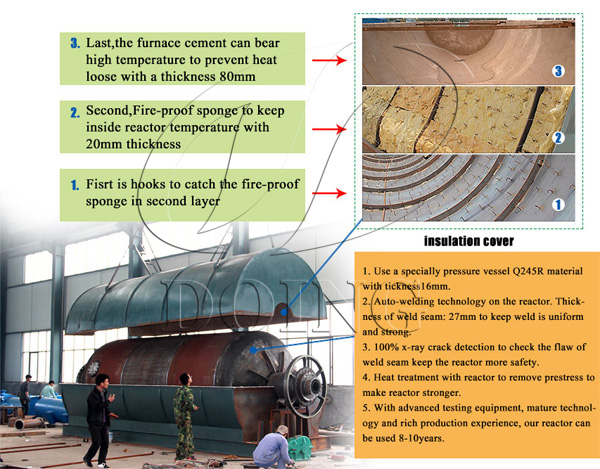

Moreover, the quality of the pyrolysis plant must be considered. Maybe high quality means high price, but it is worth since the quality of the pyrolysis plant directly affects the service life and production safety. Take pyrolysis reactor as an example here. DOING pyrolysis reactor material is made from Q245R boiler plate, which has high pressure and high temperature resistance. And DOING’s pyrolysis reactor design is strictly made accordingly to pressure vessel standard with 3-step welding process, thus longer service life than ordinary pyrolysis plant. In all, no matter what product you buy, quality is the basic factor to consider.

DOING pyrolysis reactor design

DOING pyrolysis reactor design

Finally, equipment certificates and company qualifications will also affect continuous waste tyre pyrolysis plant prices, because these certifications themselves mean high quality equipment and good after-sales service. DOING Company has been committed to waste tyre and plastic pyrolysis plant for 8 years since 2010. Our pyrolysis plants has been certified by CE, ISO and other standard and have been installed in more than 40 countries and regions. DOING Group has won the praise and trust from customers around the world.

Continuous waste tyre pyrolysis plant installed in Spain

Continuous waste tyre pyrolysis plant installed in Spain

Above all, there are many factors influencing the continuous waste tyre pyrolysis plant price. For more factors to consider when comparing the continuous waste tyre pyrolysis plant price, please feel free to contact us and we will provide you with professional advice and solutions.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.