Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

News

-

DOING News

-

Industry News

Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

Which tyre pyrolysis technology is best?

2023-03-07 / Industry News / Leave Message / Chat Online

In recent years, with the development of solid waste recycling and treatment industry, tyre pyrolysis projects are hot. Many customers have a very strong interest in this project. So in view of the needs of different customers, DOING not only insists on innovating and improving on the basis of batch type pyrolysis plant, but also develops large fully continuous design pyrolysis plant. So what's the difference? Which tyre pyrolysis technology is better?

The tyre pyrolysis technology between the two is somewhat different, each has its advantages and disadvantages, customers can choose according to their current needs.

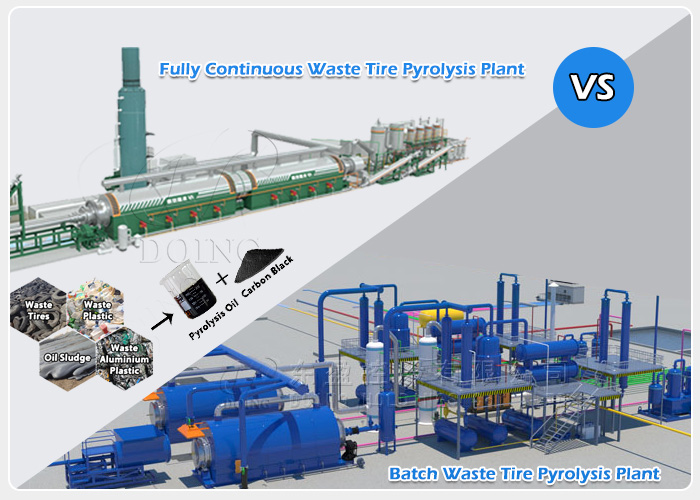

Continuous type pyrolysis plant vs batch type pyrolysis plant

Continuous type pyrolysis plant vs batch type pyrolysis plant

1) Batch pyrolysis plant. Waste tyres can be fed into pyrolysis reactor directly, without any pretreatment, so as to decrease the investment. But its daily capacity is relatively smaller, ranging from 100kg to 15tpd, and its production is based on one day one batch.

Therefore, if the customer wants to test or make a profit on the project with a small amount of capital and raw material handling, the intermittent design can be preferred.

Batch type pyrolysis plant

Batch type pyrolysis plant

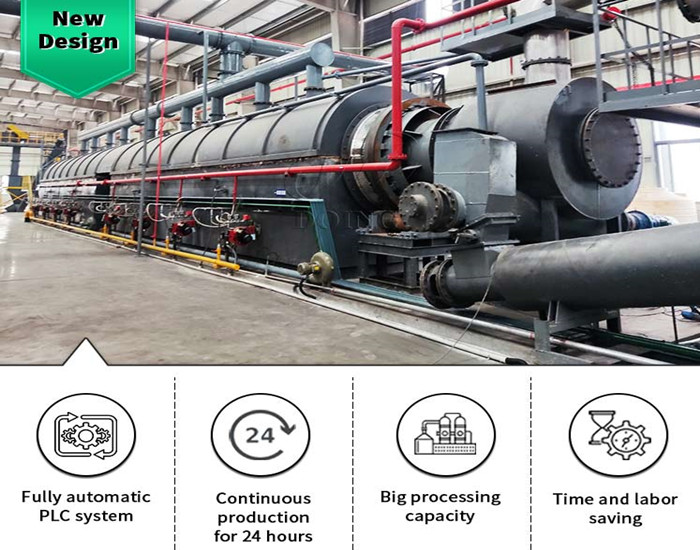

2) Continuous pyrolysis plant. Continuous tyre pyrolysis plant project scale is much larger than batch design, and its common capacity is 30 tons and 50 tons per day.

If the customer is very familiar with the tyre pyrolysis project, the raw materials are sufficient, and there is a certain economic basis, there is no doubt that this design is more suitable.

Fully continuous pyrolysis plant

Fully continuous pyrolysis plant

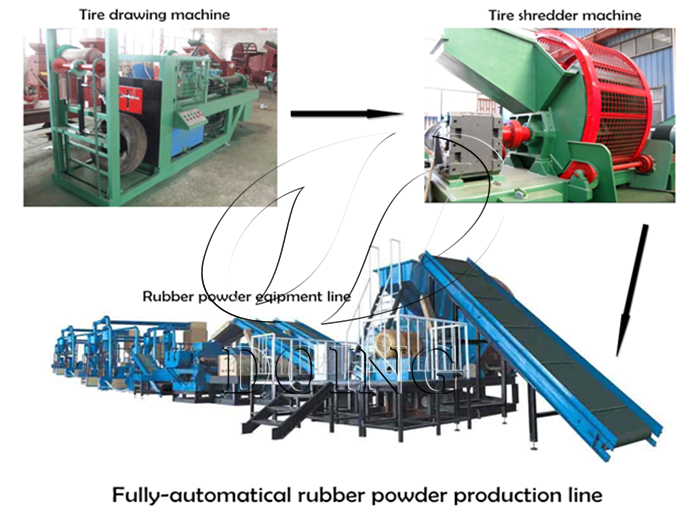

But it also has its disadvantages, that is, its raw materials need to be broken in advance, the tire needs to be broken into non-wire rubber particles, to ensure its continuous feeding and continuous slag discharge. This means that the customer needs to increase a certain budget to prepare for the crushing line.

Rubber powder production line

Rubber powder production line

Through the above description, you may have a certain understanding of the tyre pyrolysis plant project, but whether it is batch or continuous waste tyre pyrolysis plant, the equipment quality provided by DOING is the best, the after-sales service is the most guaranteed, and the process is the most mature in the industry.

Seeing this, I guess there are still many customers who have questions, so how should I choose, batch or continuous waste tyre pyrolysis plant? If you have any doubts or needs related, please do not hesitate to contact DOING, then the professional business manager will give you the best solutions.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.