Philippines customer bought 10T

Contact Us

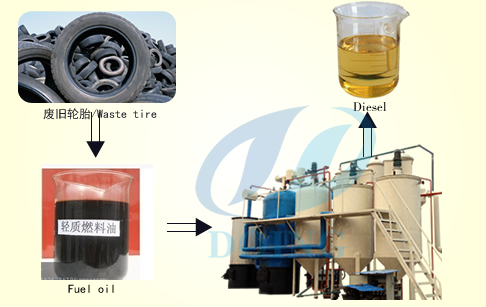

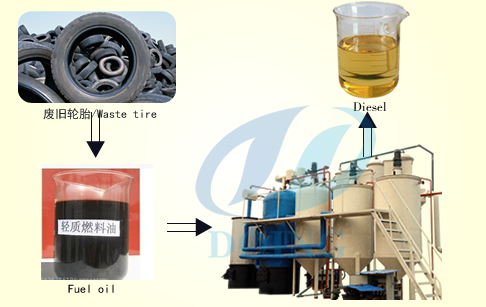

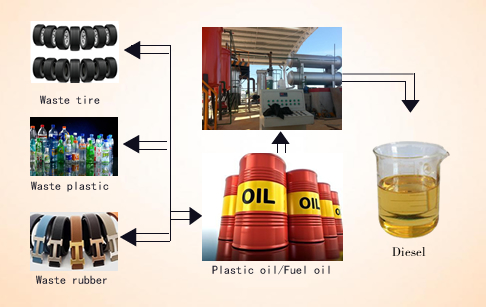

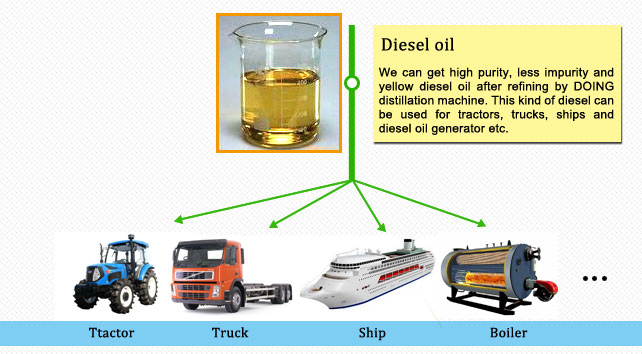

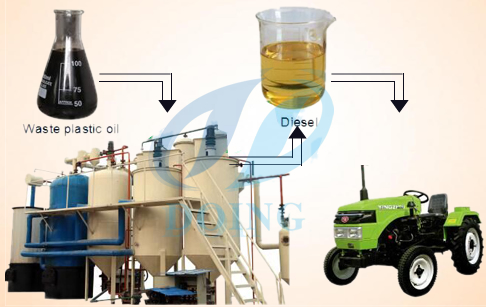

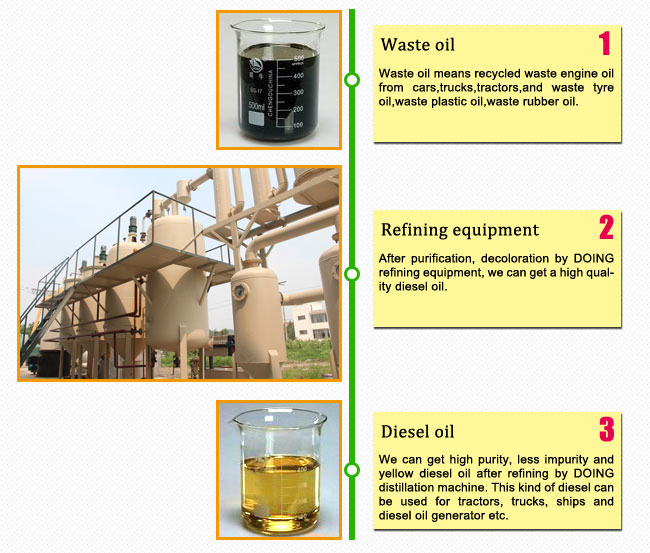

Convert waste oil to diesel refining plant

Waste oil is a problem that we all can take part in resolving. Convert waste oil to diesel refining plant is a great way ...

Skype:bonniezhao2

+86-135-2669-2320

+86-371-56771821

WhatsApp:0086 135 2669 2320

- Features:

- Technical Data:

- Application:

Waste oil

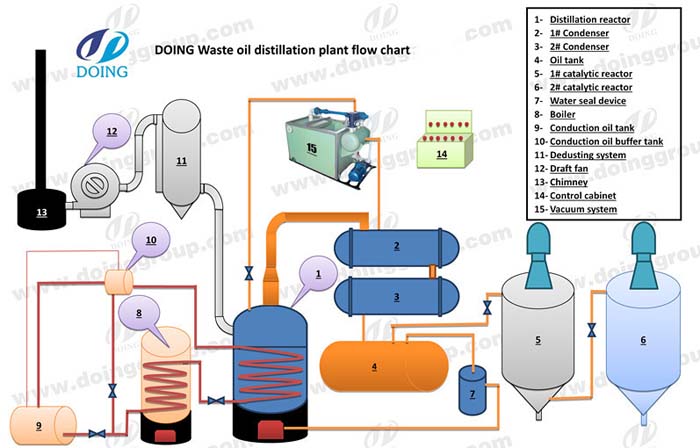

Working process of new way convert waste oil to diesel refining plant:

Convert waste oil to diesel refining plant processing

a. Pump the waste oil into reactor by oil pump.

b. Use coal/wood/natural gas/fuel oil/electricity heating the reactor.

c. After heating some time, the liquid oil will become oil gas, oil gas will be liquefied by the cooling pipe and condensers then will go into oil tank. Here we get mixed oil, or u can also call it fuel oil. If you wanna get a different quality diesel separately, through temperature control could separate it and collected into two different oil tanks.

d. Some gases (syngas) like Methane, Ethane, Propane, Butane, and Hydrogen cannot be liquefied under normal pressure and normal temperature will be recycled to fire furnace heating the reactor.

e. When use burning material heating the reactor, will produce some smoke. These smokes will go into our de-dusting system, the inside we design some high pressure nozzles, these nozzles will spraying some chemical water, the dust will be absorbed by the chemical water and flowing into the de-dusting pool. In the pool we will put some chemical which could remove the sulfur.

f. The exhaust gas will go into the chimney sucked by draft fan, when emission the exhaust gas will become steam, no pollution.

Advantages about convert waste oil to diesel refining plant

Convert waste oil to diesel refining plant

2. The pressure release device operates through water circulation, which greatly improves the security of the system.

3. The release of pressure during the production dramatically increases the output within certain time and meanwhile improves the quality of oil.

4. The heating system adopts indirect heating technology, which prolongs the machine service life; the average life time is about 7 years.