Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

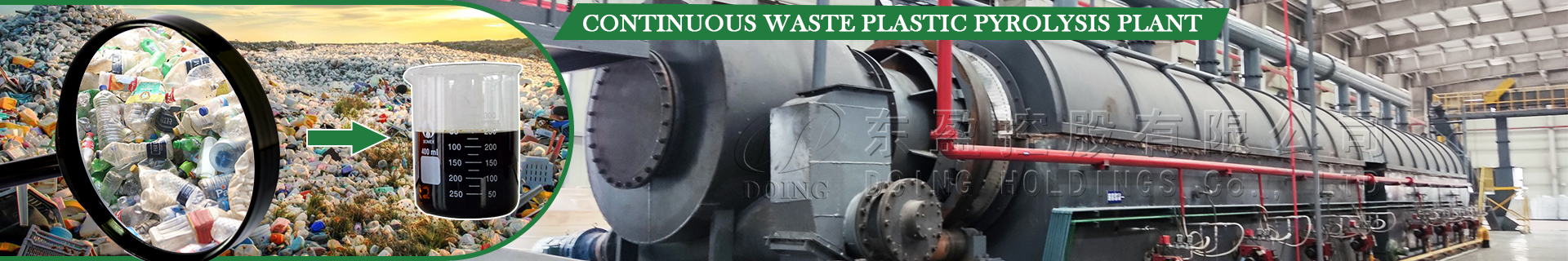

Continuous plastic to oil machine

Henan Doing produced continuous waste plastic to oil machine not only can solve the problem ,but alao can bright hugh pr...

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

- Features:

- Technical Data:

- Application:

Waste plastic to oil

In order to solve the problem ,Henan Doing produced continuous waste plastic to oil machine not only can solve the problem ,but alao can bright hugh profit for you!

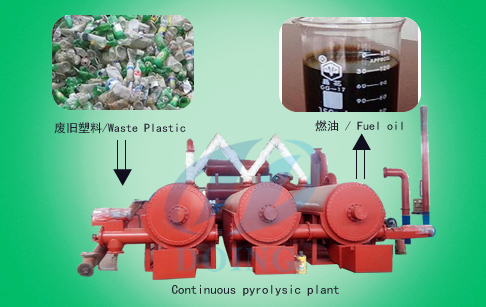

Continuous plastic to oil machine

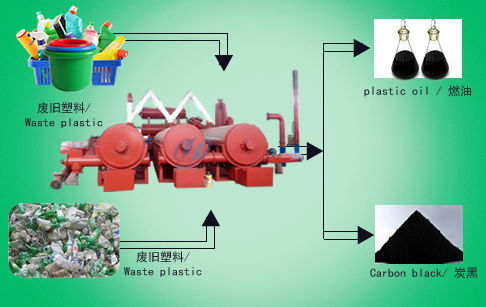

2.All the plants have passed CE, ISO, SGS certifications and have high quality guarantee. Besides, the plants are all equipped with advanced safety devices and dedusting system, which can guarantee safety and no pollution in production.

3.There is a little combustible gas generating in the plastic pyrolysis process, which could be recycled to heat the reactor as fuels. In this way, it can avoid the gas contamination and save the fuel energy.

4.The structure of reactor is 360-degree rotating, which makes the bottom of reactor heat evenly, which can lengthen the service life of reactor as well as improve the pyrolysis speed. In addition, the special catalyst and new-type condenser can also help improving the oil yield efficiency.

- Features:

- Technical Data:

- Application:

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

- Features:

- Technical Data:

- Application:

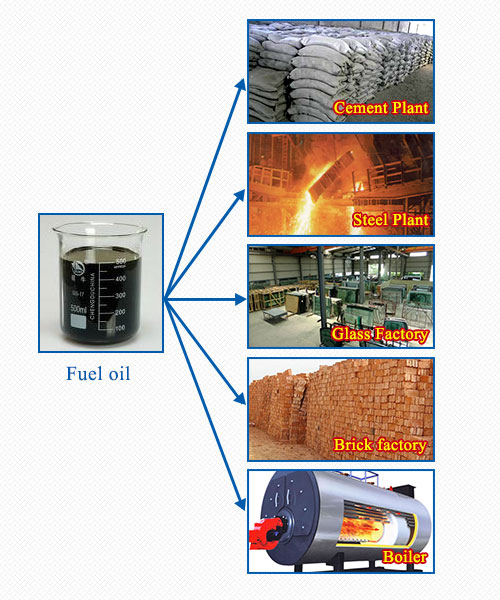

Fuel oil: Widely used as fuel oil in industries such as steel and iron factories, ceramics or chemical industries or hotels, restaurants etc. or used for generators to get electricity.

Carbon black: used for construction bricks with clay also can be used as fuel

Fuel oil application

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.