Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

Product

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Waste tyre to fuel oil pyrolysis plant project in Bangladesh

2020-12-31 / In Asia / Leave Message / Chat Online

Bangladesh is one of our major markets.Till now, we have successfully installed 4 sets 10T waste tyre to fuel oil pyrolysis plant from the year 2012 in Bangladesh. If you are in Bangladesh or would like to do this pyrolysis plant project in Bangladesh, it is worth reading the following project description, which may help you to better understand the pyrolysis project.

The first set waste tyre to fuel oil pyrolysis plant ordered by our Bangladesh customer is our 4th generation 10T waste tyre to fuel oil pyrolysis plant in 2012, and it is mainly used for extracting oil from waste tyres. After the machine installed, we were honored to be invited by our customer to see his waste tyre to fuel oil pyrolysis plant factory in Bangladesh. He said that he can also collect about 30% fuel oil from the garbage plastic through our waste tyre to fuel oil pyrolysis plant.

First set waste tyre to fuel oil pyrolysis plant installed in Bangladesh in 2012

First set waste tyre to fuel oil pyrolysis plant installed in Bangladesh in 2012

DOING second and third set waste tyre to fuel oil pyrolysis plant were exported together to Bangladesh in 2014, because they were ordered at the same time by two customers who are good friends. The pyrolysis plant they ordered is our 5th generation 10T waste tyre to fuel oil pyrolysis plant, which is mainly used to processing waste tyres. Before purchasing the waste tyre to fuel oil pyrolysis plant, they came to DOING factory to visit our factory in person. Under the guidance and help of DOING engineers, the customers had run the pyrolysis plant and put it into production formally. According to their feedback, the average oil output of our 5th generation waste tyre to fuel oil pyrolysis plant can reach 45%. And said they were very pleased with the pyrolysis project.

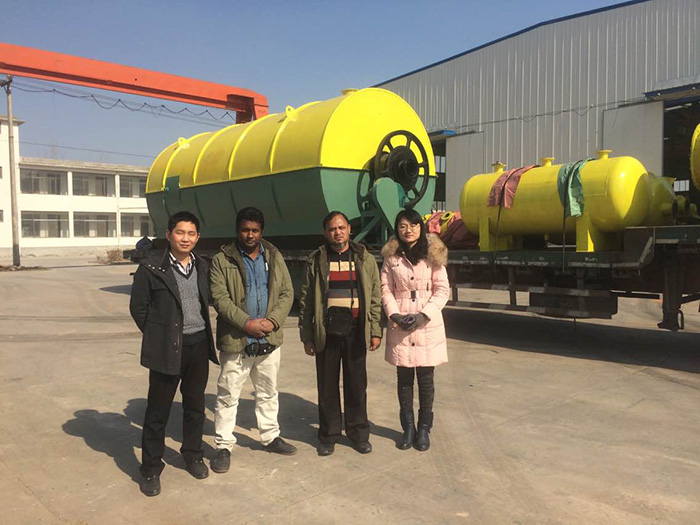

Bangladesh customers visited DOING in 2014

Bangladesh customers visited DOING in 2014

The fourth one we exported to Bangladesh is a customized waste tyre to oil pyrolysis plant in 2016. Due to the problem of a limited budget and land for the waste tyre to fuel oil pyrolysis plant project, this customer customed his pyrolysis plant in a much more simple design. Of course, for this customized pyrolysis plant, our engineer would try our best to meet the needs of customers. Meanwhile, different from other customers, he installed the pryolysis plant by himself and don't need our engineers to install it. In this way we reached a happy cooperation. After the completion of the pyrolysis plant production, he come to DOING factory to inspect the waste tyre to oil pyrolysis plant in person.

Bangladesh customer comes to inspect the pyrolysis plant in 2016

Bangladesh customer comes to inspect the pyrolysis plant in 2016

So to sum up, they are DOING pyrolysis plant project in Bangladesh, and of course we're going to be installing more and more waste tyre to oil pyrolysis plant there.

Over the years, DOING have been continuously improving the design and manufacturing of waste tyre to oil pyrolysis plant, and now our designs and technologies are quite mature. Now we manufactured waste tyre to fuel oil pyrolysis plant is the latest generation, and our newly upgraded waste oil refining plant has achieved 90% oil yield. If you want to do tyre pyrolysis project or waste oil refining project, DOING may be your best choice. Please contact us for the latest equipment quotation.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.