Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

Product

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

30TPD full continuous waste tire pyrolysis plant project installed in Kazakhstan!

2021-11-25 / In Asia / Leave Message / Chat Online

At the beginning of September 2021, the 30TPD full continuous waste tire pyrolysis plant project in Kazakhstan was successfully installed and put into operation smoothly under the assistance of DOING company's engineers!

30TPD full continuous waste tire pyrolysis plant project in Kazakhstan was successfully installed

30TPD full continuous waste tire pyrolysis plant project in Kazakhstan was successfully installed

【Project background introduction】

This Kazakhstan customer was introduced by Doing company's old customers. He and our old customers are business partners. Seeing that our old customers get considerable benefits from the waste tire pyrolysis business, he also want to build his own waste tire pyrolysis plant, so as to obtain pyrolysis oil, steel wire, carbon black for sale and get more benefits from waste tires and waste rubber recycling business.

| Location | Kazakhstan |

| Raw materials | Waste tires& rubber with steel wire |

| Equipment configuration | Full continuous waste tire pyrolysis plant and rubber powder processing machine |

| Processing capacity | 30TPD |

| Processing technology | Pyrolysis technology |

【Communication with customer】

The Kazakhstan customer formally initiated an inquiry to DOING company in July 2020. He told us that the raw materials he wanted to process were waste tires and waste rubber with steel wire, and his daily processing volume was relatively large. In this regard, our project manager specially customized a solution combining rubber powder processing machine and full continuous waste tire pyrolysis plant.

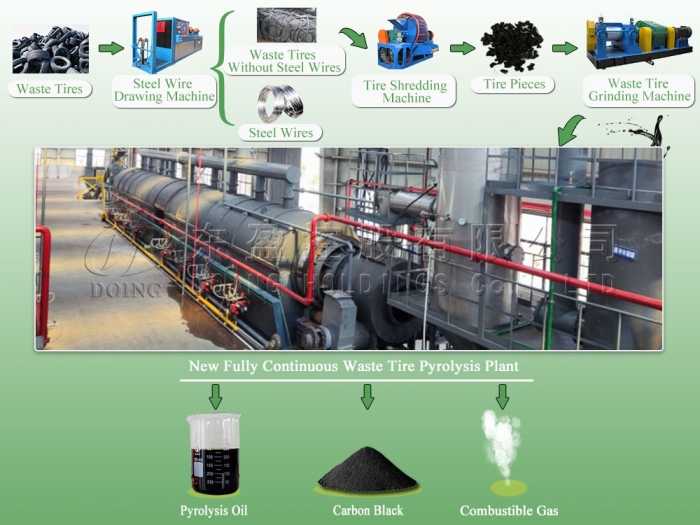

The working flow of fully continuous waste tire pyrolysis plant

The working flow of fully continuous waste tire pyrolysis plant

In this way, the steel wire in the raw materials is extracted in advance, and other raw materials are uniformly processed into rubber powder, so that the pyrolysis process is more sufficient and efficient. This pyrolysis processing solution supports continuous feeding and discharging, which has the features of large capacity, labor&time-saving and high oil output. The Kazakhstan customer is very satisfied with this solution.

After confirming the solution, the Kazakhstan customer originally planned to have a visit to DOING company and sign the contract in person. But the epidemic repeated and he couldn't come. So in September 2020, he commissioned his friends from Xinjiang, China, who had worked with him for more than 20 years, to visit DOING. And our project manager showed his friend around our factory and waste tire pyrolysis plant prototype.

DOING's strong manufacturing strength and complete equipment manufacturing machinery make his friend and this customer feel that DOING company's strict control of equipment quality. Therefore, the Kazakhstan customer placed the order contentedly.

【Equipment manufacturing and delivery】

After receiving the order, all departments of DOING company attached great importance to it, and the business department issued a production notice to the factory. It took about two months to complete the production tasks of rubber powder processing machine and 30TPD full continuous waste tire pyrolysis plant with quality and quantity.

30TPD full continuous waste tire pyrolysis plant manufacturing and delivery

30TPD full continuous waste tire pyrolysis plant manufacturing and delivery

Before delivery, the equipment quality inspectors of DOING Company carefully checked all machines meticulously and packaged all the equipment parts into containers in different categories. On January 27, 2021, all these machines were loaded and delivered to designated location.

【Equipment installation and debugging】

In August 2021, under the guidance of DOING engineer, Kazakh customer's engineer team completed the installation and commissioning of rubber powder processing machine and 30TPD full continuous waste tire pyrolysis plant. And all the machines successfully put into operation.

Fully continuous waste tire equipment installation and debugging

Fully continuous waste tire equipment installation and debugging

If you also have investing idea of setting up waste tire/plastic/rubber pyrolysis plant projects, welcome to contact DOING company and tell us your requirements. We can not only provide you with many project cases information for your reference, but also customize the best solution and equipment to help you maximize your benefits!

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.