Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

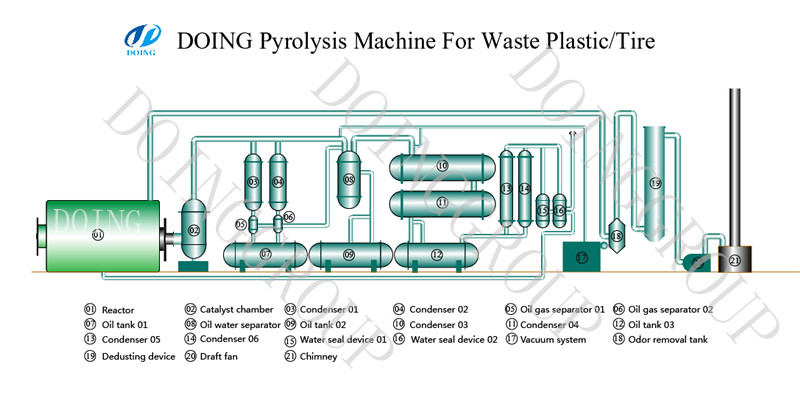

The working process of waste tire&plastic pyrolysis machine

Process principle of tire plastic pyrolysis machine: Its process is solid(tires /plastic)-------gas(oil gas)--------liqu...

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

- Features:

Process principle of tire & plastic pyrolysis machine:

Its process is solid(tires /plastic)-------gas(oil gas)--------liquid(fuel oil). High temperature pyrolysis raw material into oil gas. After cooling system, oil gas will be cooled down to liquid oil.

Pyrolysis machine

How to process waste tires and plastic by pyrolysis machine?

Firstly, put waste tires into reactor, then close the door after finished feeding Secondly, heat the reactor by fuel material like coal, wood, natural gas, fuel oil or diesel. The reactor will slowly heat, when temperature reaches about 150 ℃, oil gas will start to be generated, then go through the cooling system to be cooled into oil. At this time, waste gas will be also generated too. But we need to continue the heating by fuel material until the temperature reach the best 200℃--230℃. Then we can fire heating and start to open waste gas valve to use waste gas for heating reactor to control it in best temperature. After finished pyrolysis, it needs about 2hours for reactor cooling. Then slag carbon black and discharge steel wire. Then can start another new batch.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.