Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

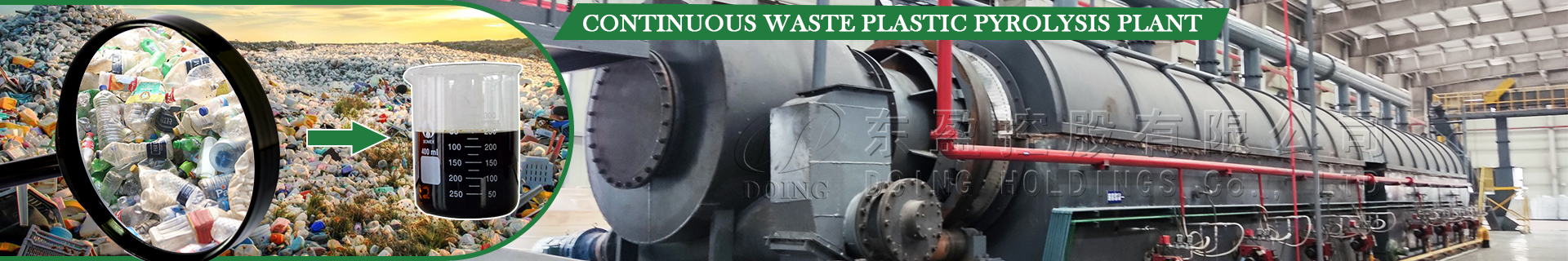

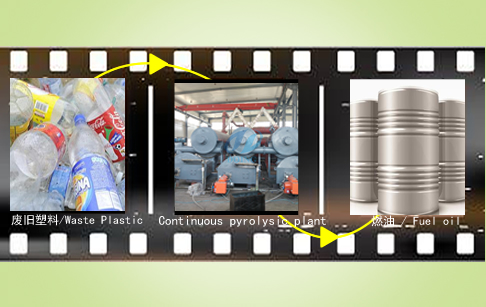

Fully automatic continuous waste plastic pyrolysis plant

Fully automatic continuous waste plastic pyrolysis plant adopts the latest pyrolysis technology can be convert waste ty...

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

- Features:

- Technical Data:

- Application:

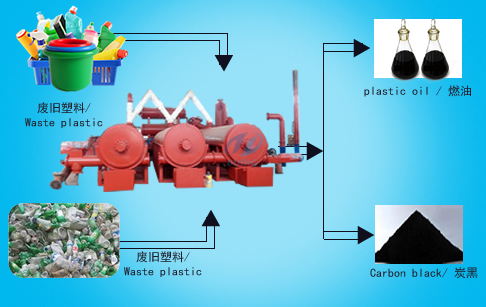

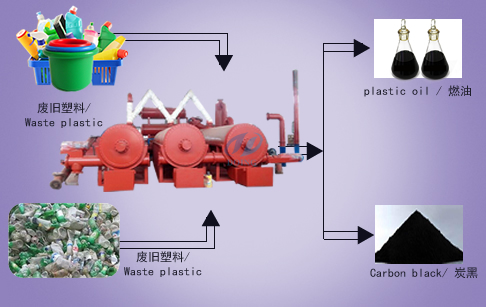

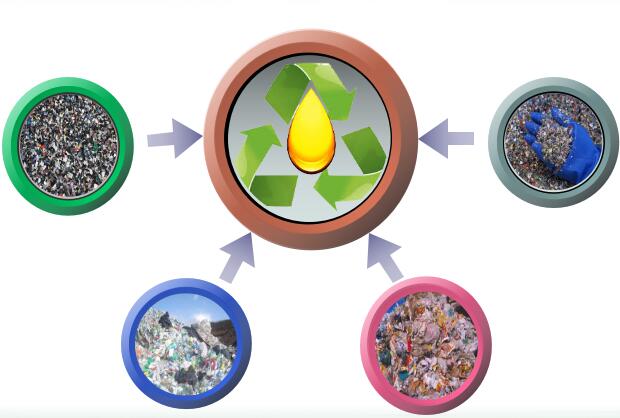

Waste plastic

Fully automatic continuous waste plastic pyrolysis plant advantage

Fully automatic continuous waste plastic pyrolysis plant

The equipment is small in size, and it has smaller occupied area, large capacity.

2. Long service life

The equipment has special anticorrosive structure, which guarantees the service life can be as long as 6-8 years.

3. Higher security

The pyrolysis plant is one kind of fully continuous, normal pressure and environmental friendly equipment. Is equipped with automatic tempering prevention device, which can greatly improve the safety performance of the equipment. The specific features of the tempering prevention device are: gas quantitative indicators treatment, gas filtration as well as tempering prevention.

4. Low raw material requirements

The raw materials don’t need to clean or classify.

5. Continuous feeding, discharging and oil generating

The continuous plant can achieve continuous feeding, discharging and oil generating in high temperature condition, and it also doesn’t return oil smoke. The feeder has special gas seal device, which is suitable for large-scale industrial continuous operation.

The gas having been disposed by the gas treatment device can supply heat for the equipment itself. The auto continuous pyrolysis plant needs other sources in the first 45 minutes, after which the equipment can make use of the heat generated by the device itself, which greatly save the outside energy.

7. High-quality oil products

The plant can generate oil products once. The fractionating tower has special structure, which doesn’t need to add catalyst in the reaction process and can generate oil with different grades. The oil becomes clear immediately and never becomes again.

8. Environmental friendly

It is absolutely environmental friendly in the production process. It doesn’t have any smoke, taste, secondary pollution or three waste: waste water, waste gas, waste solids discharged. The equipment has normal machine operation sound in the normal operation and doesn’t have any other noise.

- Features:

- Technical Data:

- Application:

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

- Features:

- Technical Data:

- Application:

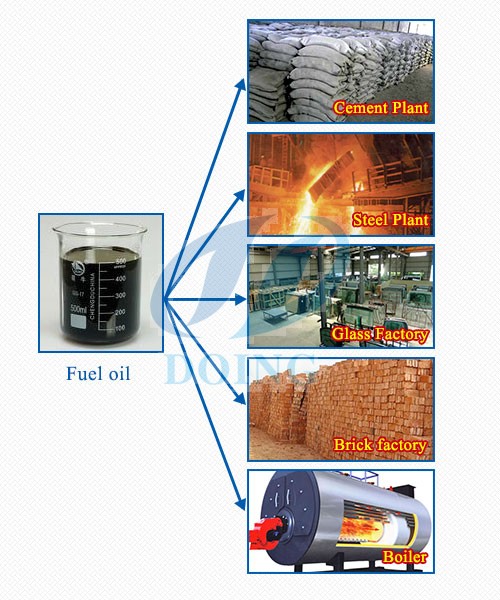

Fuel Oil (40% to 45%)

The main application of oil products produced by our fully automatic continuous waste plastic pyrolysis plant is the fuel oil that is wide used for industrial and commercial purposes. Such as power plant factory,glass factory,cement factory,ceramic fatory.

Fuel oil application

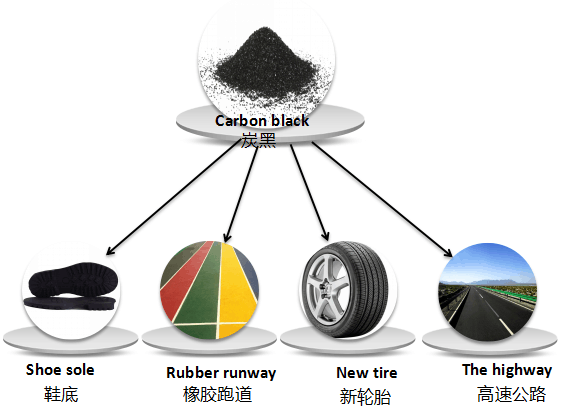

The second product of fully automatic continuous waste plastic pyrolysis plant is carbon black. The quantity of carbon black is about 30% to 35% according to tyre quality. Carbon black can application to electric cable jacketing,black nylon bag,rubber additive.

Carbon black application

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.