Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Product

Project Case

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

-

India 50TPD Fully continuous rubber pyrolysis machine installed

-

DOING 15 TPD semi-continuous tire pyrolysis equipment installed in Indonesia

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

What is continuous tire pyrolysis plant technical details?

2018-03-27 / Continuous Pyrolysis plant / Leave Message / Chat Online

Tchnical data of continuous tire pyrolysis plant production

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

The final products of DoingGroup's continuous pyrolysis plant have a wide usage in our daily life, specific usages are as follows:

Fuel oil usage

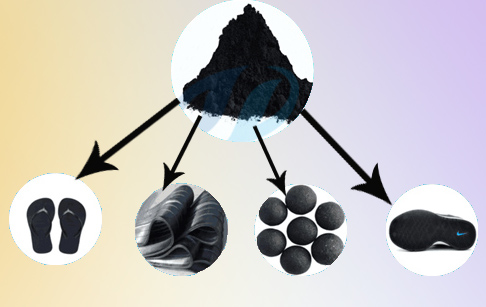

Carbon black

Steel wire usage

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.