Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Product

Project Case

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

-

India 50TPD Fully continuous rubber pyrolysis machine installed

-

DOING 15 TPD semi-continuous tire pyrolysis equipment installed in Indonesia

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

What are the main features of the fully continuous tyre/plastic pyrolysis machine?

2021-02-02 / Continuous Pyrolysis plant / Leave Message / Chat Online

Recently, used tyres and plastic waste are produced increasingly every year. It’s a big problem to deal with them. One efficient way to recycle them is pyrolyzing them. Pyrolysis plant is manufactured to do this job. Fully continuous tyre/plastic pyrolysis machine has two basic features--one is that it can pyrolyze tyres or plastics into useful renewable resources, the other is that it’s continuous or called automatical--and an extended advantage, which is friendly to the environment.

Fully continuous tyre/plastic pyrolysis machine

Fully continuous tyre/plastic pyrolysis machine

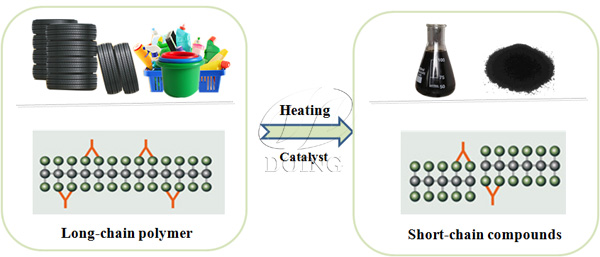

1. Principle of pyrolysis machine

Same as batch type waste tyre/plastic pyrolysis plant, the main function of fully continuous tyre/plastic pyrolysis machine is pyrolysis. Pyrolysis is the thermal decomposition of materials at high temperatures without oxygen. It is most commonly used in the treatment of organic materials. It will change the chemical composition of materials from polymers into smaller molecules. Fully continuous tyre/plastic pyrolysis machine can pyrolyze waste tyres or plastics into pyrolysis oil, carbon black, steel wire (for tyres) and combustible gas. In this process, the required equipments are pyrolysis reactor, condensing system, oil tank, tail gas cleaning and odor removal system, control cabinet, carbon black discharge device, smoke cleaning system, desulfurization & purification tower, etc. If you want to know more about workflow of the fully continuous tyre/plastic pyrolysis machine, please see at : [How does the fully continuous waste tyre pyrolysis plant work?]

Principle of pyrolysis machine

Principle of pyrolysis machine

2. Adopt PLC system

All of the working process of the fully continuous tyre/plastic pyrolysis machine is automatically controlled by the PLC system. It can feed tyres/plastics and discharge residues (carbon black and steel wire) continuously without a stop, which greatly reduces the cost of time and labors. What’s more, its accurate calculated pyrolysis system can make sure fully pyrolysis of the tyres, thus markedly improving oil yield.

Fully continuous tyre/plastic pyrolysis machine is automatically controlled by the PLC system

Fully continuous tyre/plastic pyrolysis machine is automatically controlled by the PLC system

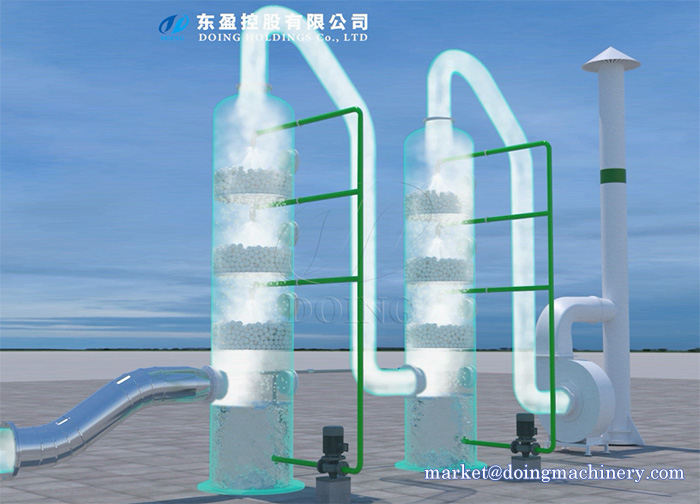

3. High environment protection

The processes of feeding and dischargeing are both sealed, which can aviod dust pollution. And the gas that can’t be condensed in condensing process will be recycled to heat the pyrolysis reactor, which can save much energy. About waste gas produced by the combustion, it will be sent to the smoke cleaning system and desulfurization & purification tower to meet the environmental protection standards before released. We really attach great importance to the environmental protection, So you can rest assured in terms of environmental pollution.

Desulfurization & purification tower of fully continuous tyre/plastic pyrolysis machine

Desulfurization & purification tower of fully continuous tyre/plastic pyrolysis machine

And our newly designed fully continuous tyre/plastic pyrolysis machine has large processing capacity and takes up less space. If you want to increase production and efficiency, it will be a good choice for you.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.