Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

What is the difference of batch and continuous waste tyre pyrolysis plant?

2021-01-30 / Continuous Pyrolysis plant / Leave Message / Chat Online

Our waste tyre pyrolysis plant has two models, batch one and continuous one. Many customers who want to do the waste tyre recycling oil project have no clear idea about the difference of batch and continuous waste tyre pyrolysis plant. Most of time, these two plants are taken for two different kinds of machine and have different oil output. So I am writing to clarify the difference of batch and continuous waste tyre pyrolysis plant.

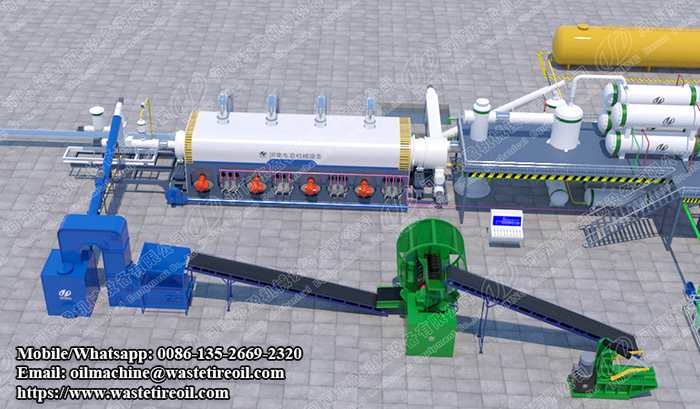

DOING batch and continuous waste tyre pyrolysis plant

DOING batch and continuous waste tyre pyrolysis plant

Firstly, batch waste pyrolysis plant and continuous waste pyrolysis plant have same application, which is used to extract fuel oil from waste tyre or plastic. And the oil output for same raw material also has no big difference.

Then what is the difference of batch and continuous waste tyre pyrolysis plant?

The main difference of batch and continuous waste tyre pyrolysis plant is the degree of automation.

For continuous waste tyre pyrolysis plant, just as its name implies, it can work continuously, such as feeding continuouly, oil producing continuouly and carbon black slagging continuously, no need to stop for reactor cooling down and carbon black slagging, it can be continuous working without stop for one month.

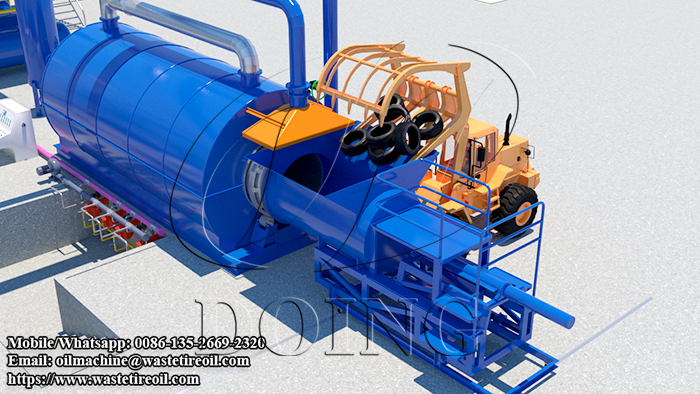

The continuously feeding system of continuous waste tyre pyrolysis plant

The continuously feeding system of continuous waste tyre pyrolysis plant

For batch waste pyrolysis plant, the process is feeding, then heating for start up, then oil producing , then reactor cooling down, then carbon black slagging, and finally taking out steel wire from the reactor, each process has to start after the former process finished. The batch waste tyre pyrolysis plant should have a stop to finish the work in one batch operation.

The other difference of batch and continuous waste tyre pyrolysis plant is the form of the feedstock.

For continuous waste tyre pyrolysis plant, the tyre, rubber and plastic should be as clean as possible, raw material should be shredded, and tyre should be crushed into 10Mesh rubber powder and all steel wire removed in order to make sure the smooth feeding and discharging and keep the plant running continuously.

For batch waste pyrolysis plant, whole tyre can be fed into reactor without any cutting, waste plastics can be fed directly without doing cleaning and selection work. Batch waste pyrolysis plant is not picky on the form of raw material.

Waste tyres can be put into the batch waste tyre pyrolysis plant directly

Waste tyres can be put into the batch waste tyre pyrolysis plant directly

No matter continuous model or batch model, the principle of converting waste tyre /plastic into fuel oil is same, their main difference is the degree of automation, besides, during the operation, continuous waste tyre pyrolysis plant is better sealed than the batch one, so it is relatively more environmentally friendly. If you cannot make a choice between batch and continuous waste tyre pyrolysis plant, please feel free to send your inquiry.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.