Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Product

Project Case

-

DOING DY-15 Waste Tire Pyrolysis Machine Project Successfully Installed in Kenya

-

DOING 45,000 Tons/Year Waste Plastic Pyrolysis Project in Vietnam Successfully Commissioned

-

DOING Tire & Plastic Pyrolysis Distillation Plant Successfully Installed in Fiji

-

DOING 50TPD Continuous Oil Sludge Pyrolysis Production Line Successfully Installed in China

-

DOING Installed 15-Ton Tank Bottom Sludge Pyrolysis Equipment for Colombian Repeat Client

-

DOING 30TPD Mazut Oil Distillation Plant Successfully Installed in Kazakhstan

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

-

India 50TPD Fully continuous rubber pyrolysis machine installed

-

DOING 15 TPD semi-continuous tire pyrolysis equipment installed in Indonesia

How to improve the oil yield of waste tire pyrolysis plant?

2021-06-15 / Continuous Pyrolysis plant / Leave Message / Chat Online

For customers who want to carry out the waste tire pyrolysis projects, the more question asked by them is the oil output rate of waste tire pyrolysis plant. Generally speaking, the oil output rate of waste tire pyrolysis plant is mainly determined by the raw material--tires. Taking 10 tons of waste tires as an example, we can obtain about 4-4.5 tons of pyrolysis oil. That is to say, the oil output rate of waste tire pyrolysis plant is 40-45%. Then,what can we do to increase the oil output rate of waste tire pyrolysis plant? We can discuss this issue from the following aspects.

waste tire pyrolysis plant

waste tire pyrolysis plant

1. Raw material selection of waste tire pyrolysis plant.

Waste tires can be divided into car tires, truck tires, motorcycle tires, bicycle tires,etc. The oil yield of waste tires is related to the rubber content and the degree of wear. Generally, the higher of rubber content and the lighter wear of waste tires, the higher of oil yield of waste tires. Therefore, when choosing raw materials for waste tire pyrolysis plant, customers can choose waste tires with higher rubber content or lighter wear, so as to further increase the oil yield of waste tire pyrolysis plant.

Oil yield of different waste tyre

Oil yield of different waste tyre

2. Technology of waste tire pyrolysis plant.

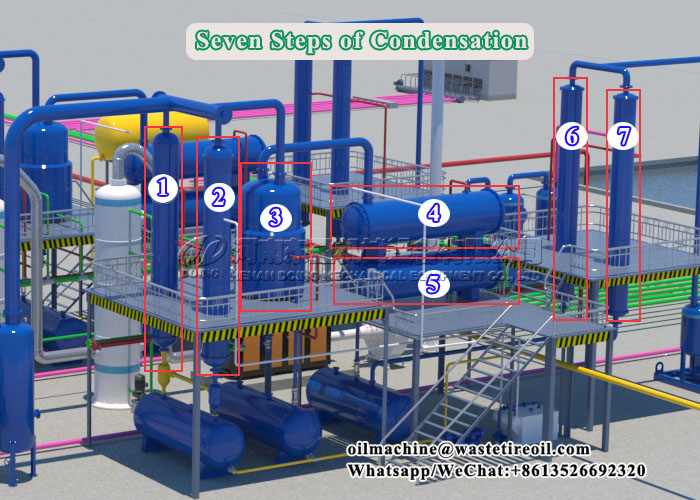

During the operation process of waste tire pyrolysis plant, the technology of waste tire pyrolysis plant will greatly affect the oil yield of waste tires. For example, the cooling system. The waste tire pyrolysis plant first pyrolysis the waste tires into oil gas, and then the cooling system cools the oil gas down into pyrolysis oil. Therefore, the cooling system of waste tire pyrolysis plant is particularly important.Doing Group waste tire pyrolysis plant adopts the three-step cooling system, including 2 vertical condensers, 2 horizontal condensers and 2 condensation towers. The cooling area is 1.5 times that of oil gas, and the heat exchange area is large, so the oil gas can be fully cooled, thereby technically improving the oil yield of the waste tire pyrolysis plant.

In addition, customers can also determine whether oil gas are completely cooled down into pyrolysis oil through the carbon black produced by the waste tire pyrolysis plant. If the discharged carbon black is lumpy, it means that the oil gas has not been completely cooled; if the discharged carbon black is powder, it means that the oil gas has been completely cooled.

Cooling system

Cooling system

In addition to the two factors mentioned above, the operating specifications of the operators will also affect the oil yield of the waste tire pyrolysis plant. Doing Group has dedicated to the waste tire pyrolysis plant for more than 10 years, having our own production factory and professional installation team. If you want to know more information about waste tire pyrolysis plant, welcome to contact us feel free.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.