Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

What safeguards do you have on your waste tyre pyrolysis plant?

2021-07-12 / Continuous Pyrolysis plant / Leave Message / Chat Online

Waste tire pyrolysis plant is a relatively large equipment, so many customers are more concerned about the safety of the waste tire pyrolysis plant . For safety reasons, Doing Group waste tire pyrolysis plant is equiped with perfect safety devices, including Oil-water separator, Water seal and Vacuum device. Next, let's see the funcitons of these safety devices.

Waste tire pyrolysis plant

Waste tire pyrolysis plant

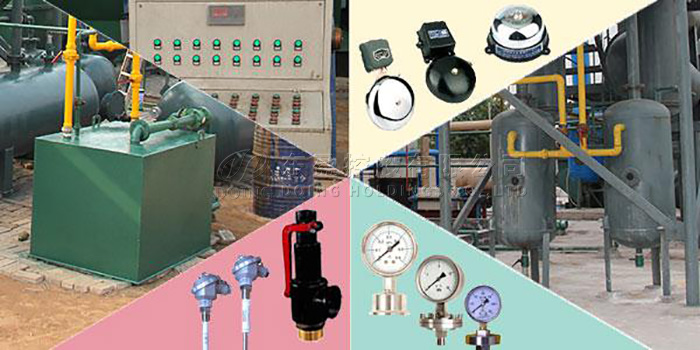

1.We have 2 pressure valves(one is in front of reactor and the other is behind of the reactor), and one alarm bell. We set a number on the pressure gage, like 0.3-0.4mpa, once the pressure of the waste tire pyrolysis machine reach this number, alarm bell will ring, if there is no one around the waste tyre pyrolysis plant, pressure valve will open automatically to release the pressure inside the pyrolysis reactor;

2. Oil-water separator. There is water inside the oil-water separator, gas pipe is under the surface of water, because the pressure of water, the oil gas cannot go back to reactor, which can prevent the gas reflux to the reactor and avoid blast;

3.Water seal .The function of water seal device is for preventing the back flow of tail gas(uncondensable gas);

4. Vaccum device. Vacuum system is the special devices of our waste tyre pyrolysis plant, which can ensure the whole plant, operate under a negative pressure, and escape the hazard of high pressure in the inner system;

Safety devices

Safety devices

Doing Group has dedicated to the waste tire pyrolysis plant for more than 10 years, having our own production factory and professional installation team, can provide customers with high quality service snd reliable equipment. If you want to know more information about waste tire pyrolysis plant, welcome to contact us feel free.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.