Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

What machine can convert rubber tyres into fuel oil?

2022-05-24 / Continuous Pyrolysis plant / Leave Message / Chat Online

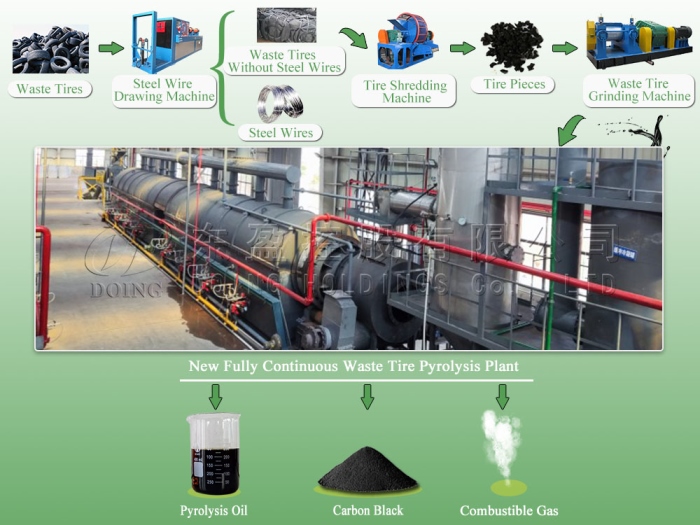

Nowadays, there are tons of waste rubber tyres around the world and to reduce the pollution it causes to the environment, many countries seek the recycling machines to convert rubber tyres into fuel oil. The new efficient environmental protection—DY series waste rubber tyres pyrolysis plant researched and manufactured by DOING Company is the popular and ideal choice to convert rubber tyres into fuel oil. Waste rubber tyres pyrolysis plant takes the high temperature pyrolysis technology to process rubber tyres into fuel oil. The whole rubber tyres to fuel oil converting process is at normal pressure, and there is no need to wash the rubber tyres raw material firstly, it can be put into the reactor for pyrolysis directly and then heating, catalyzing, pyrolysis and cooling into fuel oil.

Waste tyres to oilpyrolysis plant

Waste tyres to oilpyrolysis plant

Here is the detailed working process of converting rubber tyres into fuel oil:

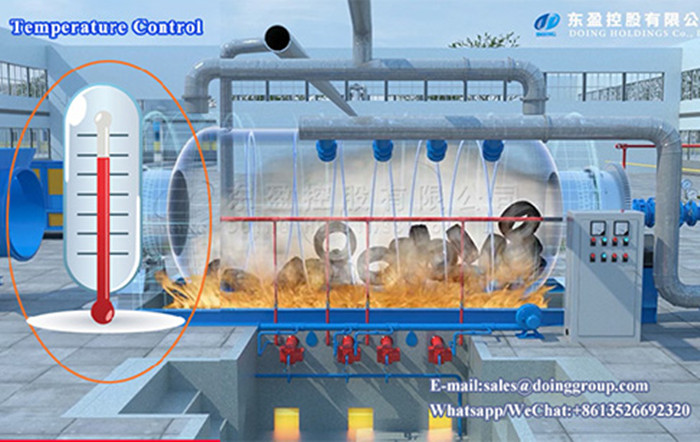

A. Put raw materials into reactor by auto-feeder, then heat the reactor. Do not stop heating the reactor until the temperature reaches nearly 250 degrees Celsius, waste rubber tyres will be transferred to oil gas.

B. The oil gas will be cooled by condenser to liquid oil then collected by oil tank.

C. The exhaust gas which can not be cooled to liquid oil will be recycled to heat the reactor. Smoke produced during processing can achieve national emission standard through dual desulfurization and dusting removal device.

D. After fuel oil production is finished, you can get the carbon black.

Heating system

Heating system

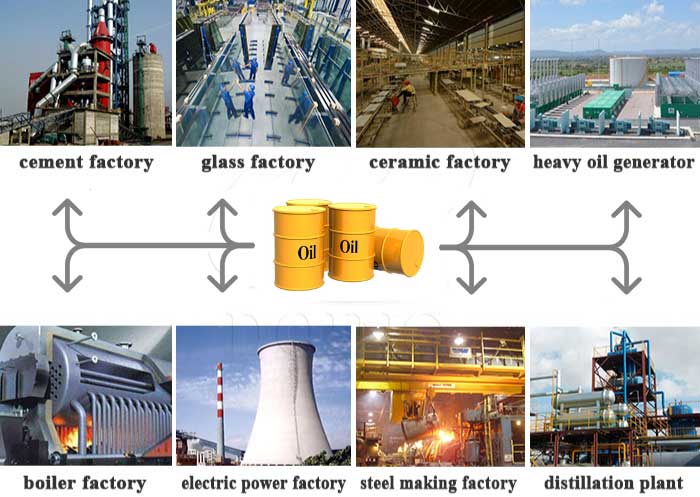

From waste tire pyrolysis plant, 4 kinds of products can be obtained: fuel oil, carbon black, steel wire, and incondensable gas. Fuel oil is widely used in industries, such as steel factory, heavy oil generator, cement factory, and boiler heating etc. And the Carbon black can be made into pellets for making new rubber products. Steel wire could be sold to the recycling station or steel mill for remelting. The incondensable gas is recycled to heat the pyrolysis reactor, saving energy.

The application of pyrolysis plant

The application of pyrolysis plant

Converting waste rubber tyres to fuel oil project is not only a profitable environmental friendly business, but also helps to reduce the global reliance on oil by producing fuel oil. Just feel free to contact DOING Company if you are interested in this waste rubber tyres to fuel oil pyrolysis machine. We can customize you the most suitable batch/continuous waste rubber tyres to fuel oil pyrolysis machine based on your situation!

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.