Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

News

-

DOING News

-

Industry News

Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

What is the cost of pyrolysis furnace?

2025-02-28 / Industry News / Leave Message / Chat Online

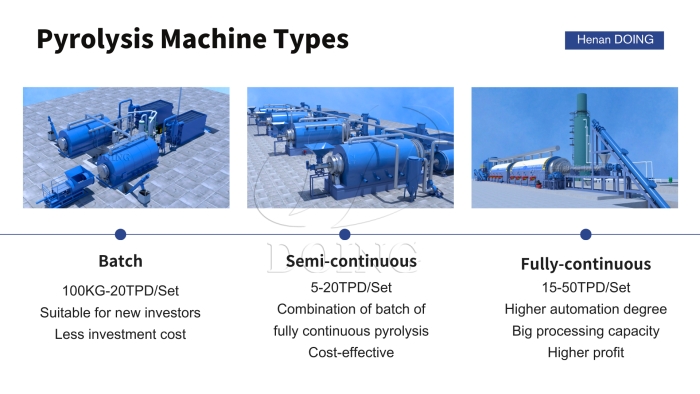

Pyrolysis furnace is a very popular machine used in the waste treatment and recycling industry to recycle tires, plastics and sludge into valuable fuel oil. To buy such a pyrolysis furnace, you need to prepare enough funds. But the detailed cost of a pyrolysis furnace can vary depending on factors such as machines type, capacity and configuration. DOING pyrolysis furnaces are divided into three types according to the form of equipment: batch type, semi-continuous type and fully continuous type.

DOING pyrolysis furnace three types

DOING pyrolysis furnace three types

For batch type pyrolysis furnace, the capacity is 100KG/500KG/1TPD/2TPD/5TPD/10TPD/12TPD/15TPD/18TPD/20TPD. The price is from 15000$ to 120000$. The batch type pyrolysis furnace can be fed with complete raw materials and needs to be shut down continuously to input raw materials and output products, and repeatedly cool and heat, completing a pyrolysis cycle in an average of 22 hours.

DOING batch type pyrolysis furnace details

DOING batch type pyrolysis furnace details

For semi-continuous pyrolysis furnace, the capacity is 5TPD/10TPD/12TPD/15TPD/18TPD/20TPD. The price is from 30000$ to 160000$. The semi-continuous furnace needs to be fed with crushed raw materials, which are transported to the reactor through a conveyor screw. While feeding, slag is discharged, which effectively saves cooling time and achieves the production efficiency of two days and three furnaces. Compared with batch type pyrolysis furnace, the operation is more automated.

DOING semi-continuous type pyrolysis furnace for sale

DOING semi-continuous type pyrolysis furnace for sale

For fully-continuous pyrolysis furnace, the capacity is 15TPD/20TPD/30TPD/40TPD/50TPD. The raw material need to be strict, under 5mm rubber powder, so expect the tyre further process line, only the fully continuous pyrolysis furnace price need about 500,000$ to 1,100,000$. The fully continuous pyrolysis furnace adopts PLC control operation, with a high degree of automation, continuous feeding, continuous oil discharge, and continuous slag discharge. It runs 24 hours a day and can run continuously for 30-40 days.

DOING fully-continuous pyrolysis furance

DOING fully-continuous pyrolysis furance

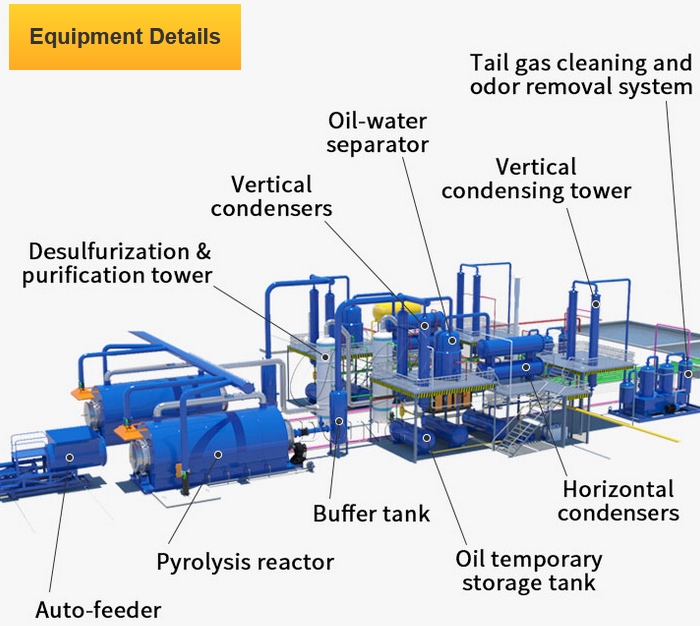

The above is an approximate cost. The specific price of the pyrolysis furnace also depends on the specific configuration: raw material pretreatment device, environmental protection device, safety device, etc.; the material of the reactor: Q245R, Q345R, stainless steel; the type of raw material is determined: the plastic pyrolysis furnace is necessary to match equipment to remove the wax produced during the pyrolysis process; the oil sludge pyrolysis furnace is necessary to match equipment to prevent sludge from sticking on the pyrolysis furnace.

DOING environmental protection device

DOING environmental protection device

DOING pyrolysis furnace technology is very mature in whole market, which have been exported to more than 100 countries. Every day we have clients gave us good feedback, also almost every week we have clients come for visiting. If you have time, you are welcome to make a video appointment or come to visit our office and factory in person. Welcome your coming!

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.