Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Waste rubber pyrolysis plant

Waste rubber pyrolysis plant, is mainly used for recycling waste rubber to obtain pyrolysis oil and carbon black in an e...

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

- Features:

- Technical Data:

- Application:

Waste rubber pyrolysis plant, one of the most popular products of DOING GROUP, is mainly used for recycling waste rubber to obtain pyrolysis oil and carbon black. It realizes the environmentally friendly treatment and reutilization of waste rubber at the same time brings great profits to people.

The complete set of waste rubber pyrolysis equipment mainly includes automatic feeder, pyrolysis reactor, condenser system, deodorant removal device, vacuum device, carbon black screw conveyor and dust removal device.

The 3D picture of different types waste rubber pyrolysis equipment

The 3D picture of different types waste rubber pyrolysis equipment

The whole system of DONG's waste rubber pyrolysis plant is introduced in detail as below:

1. Automatic feeder (optional)

The automatic feeding machine is feeding auxiliary equipment, which can save the investment for labor&time and improve efficiency. It can also ensure workers' safety to a certain extent.

2. Pyrolysis reactor

The pyrolysis reactor is the host of the whole production line. It is used to heat rubber, cracking it into oil and gas and carbon black. Both ends of the reactor adopt an arc head, which can achieve seamless welding and has strong pressure resistance (high safety performance).

3. Condenser system

The condenser system is used to cool oil and gas into pyrolytic oil. A four-step tubular condensation system is adopted for circulating water cooling. While ensuring the quality of oil products, the oil yield can be guaranteed. Detachable flanges are provided at both ends of the condenser for easy cleaning and maintenance.

4. Odor removal device (optional)

The exhaust odor removal device is used to purify some uncoolable oil and gas. These are called non-condensable gases. The purified hydrogen sulfide gas can be removed, so it can be used in combustion and heating reactors, saving fuel and avoiding odors.

5. Vacuum equipment (optional)

The vacuum device is one of the safety devices. After the pyrolysis process is completed, the residual oil and gas in the reactor is extracted and discharged again through the condensation system and deodorizer, which can not only increase the amount of oil produced, but also ensure the safety and odor-free when opening the furnace door.

6. Carbon black screw conveyor (optional)

The carbon black screw conveyor is used to discharge the carbon black from the closed space, which can avoid carbon black in the delivery of flying around and keep the factory environment clean.

7. Dust removal equipment

Dust removal equipment is used to treat the flue gas produced by fuel combustion. It can remove dust and particles in soot, control emissions, and meet national environmental standards.

The overall design of waste rubber pyrolysis plant is compact and mature, which can not only ensure the safe and stable operation of machine so as to guarantee the investor’s profit, but also meets the national "Comprehensive Air Pollutant Emission Standard" to realize the environmentally friendly recycling and reutilization of waste rubbers.

- Features:

- Technical Data:

- Application:

| No. | Items | Contents | ||

| 1 | Equipmenttype | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Rawmaterial | Waste tyre | Waste tyre | Waste tyre |

| 3 | Structuralform | Horizontalrotation | Horizontalrotation | Horizontalrotation |

| 4 | 24-hourCapacity | 6ton | 8ton | 10ton |

| 5 | Oilyield | 2.7-3.3ton | 3.6-4.4ton | 4.5-5.5ton |

| 6 | Operatingpressure | Normal | Normal | Normal |

| 7 | MaterialofpyrolysisReactor | Q245R | Q245R | Q245R |

| 8 | ThicknessofpyrolysisReactor | 16mm | 16mm | 16mm |

| 9 | RotatespeedofpyrolysisReactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Totalpower | 19KW | 19KW | 19KW |

| 11 | Modeofcooling | Watercooling | Watercooling | Watercooling |

| 12 | Coolingareaofcondenser | 100sqm | 100sqm | 100sqm |

| 13 | Kindoftransmission | Internalgeardrive | Internalgeardrive | Internalgeardrive |

| 14 | NoisedB(A) | ≤85 | ≤85 | ≤85 |

| 15 | SizeofReactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Workingform | Intermittentoperation | Intermittentoperation | Intermittentoperation |

| 17 | Deliverytime | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

- Features:

- Technical Data:

- Application:

DOING Company’s waste rubber pyrolysis plant can ensure that the waste rubber is efficiently and effectively converted into pyrolysis oil and carbon black.

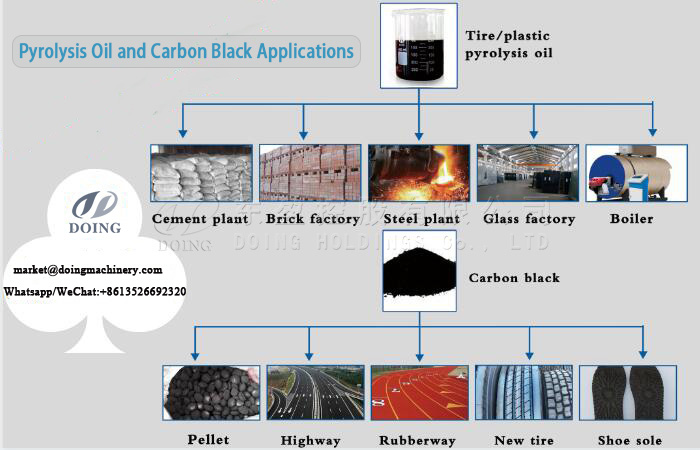

The obtained pyrolysis oil can directly replace fuel oil for industrial or boiler heating, such as cement plants, steel plants, glass plants, etc.; and the pyrolysis oil can also be refined into diesel for alternative fuel and power plants, agricultural machinery, etc. As for the carbon black, it can be used for industrial heating by briquetting combustion, and its combustion calorific value is equivalent to that of coal, and can be used directly instead of coal; or be milled and refined to different degrees and used as additives for paint pigments, rubber products, etc.

The applicaytion of waste rubber pyrolysis plant

The applicaytion of waste rubber pyrolysis plant

In addition to processing waste rubber, waste rubber pyrolysis plant can also achieve multiple uses, such as converting waste tires, waste plastics, sludge and other municipal solid wastes and even hazardous wastes into fuel. With soaring fuel prices and high demand for oil today, investing in similar waste rubber pyrolysis plant projects is undoubtedly lucrative. Some countries even issue relevant policies and give subsidies to support such pyrolysis plant projects.

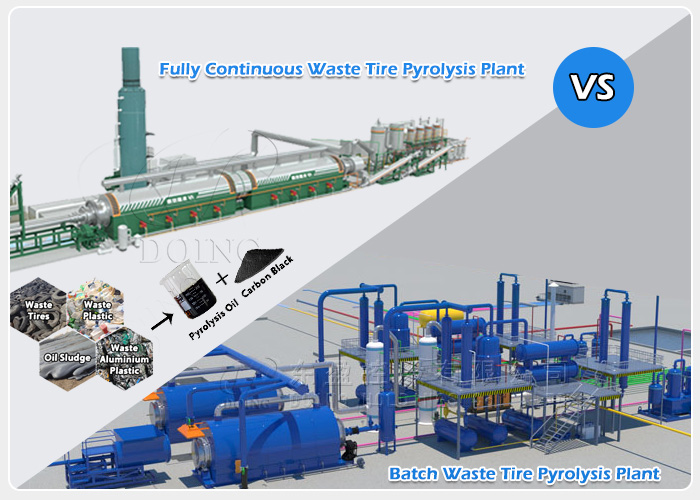

DOING GROUP is a professional manufacturer of pyrolysis plants. With more than 10 years of manufacturing experience, we can provide and customize both continuous type and batch type pyrolysis plants with different capacities to reach different demands. If you want to purchase or consult the waste rubber pyrolysis plant, welcome to contact us. We will provide you with a comprehensive plan according to your situation and needs.

Previous: Nothing

Next: Tire pyrolysis process

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.