Product

Project Case

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

-

India 50TPD Fully continuous rubber pyrolysis machine installed

-

DOING 15 TPD semi-continuous tire pyrolysis equipment installed in Indonesia

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Tire pyrolysis process

The waste tire pyrolysis process is the process of cracking waste tires, waste plastics and waste rubber into oil and ga...

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

- Features:

- Technical Data:

- Application:

Tire pyrolysis plant

Tire pyrolysis plant

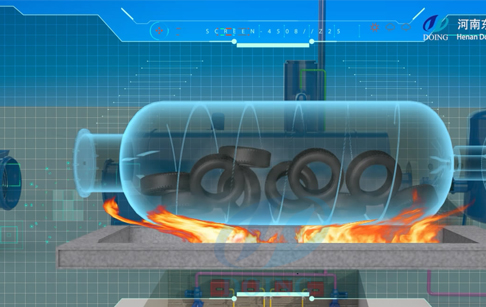

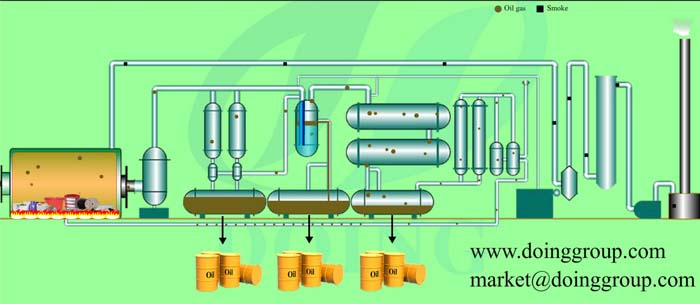

The waste tire pyrolysis process is the process of cracking waste tires, waste plastics and waste rubber into oil and gas by using chemical pyrolysis principle. The whole waste pyrolysis plant is formed by 13 parts, including reactor ,driving device ,vertical catalytic chamber, vertical condenser, oil and water separator, horizontal condenser , oil tank, water seal device, vacuum system , dedusting device, draft fan, chimney.

Tire pyrolysis process:

Tire pyrolysis process

Tire pyrolysis process

1. Put the waste tires into the reactor. Don't get too wet as a waste tyre for raw materials. Otherwise, steam will be vaporized before the reactor reaches 100 degrees, which will affect the purity of the collected oil and gas. When the reactor temperature reaches 280 degrees, the tire begins to crack, and the oil and gas production begins, and the effect is best between 280 and 320.

2, The oil and gas produced by the tire pyrolysis process flow through the catalytic chamber slowly, which will make them fully cooling. Due to the oil and gas in the catalytic chamber is from bottom to top, heavy oil will settle to the bottom after touching the wall, further improving the purity of the oil and gas. After all the pyrolysis process finished ,we should clear oil residueat at the bottom of catalytic chamber.

3. The oil and gas flow through the vertical condenser, which is then stored in the oil tank after cooled. There is a large amount of oil and gas, and the vertical condenser will produce natural negative pressure, which will reduce the pressure on the reactor and will not be easily blocked .After that, the uncooled oil and gas are further separated from the oil and gas separator. The remaining oil and gas passes through the second condenser, the third condenser, to ensure that the oil and gas are fully cooled and the oil yield is the largest. The second condenser is a horizontal condenser, whose cooling area is larger than the vertical one.

4. After these three condensers, the oil and gas are basically completely condensed, and the residual is non-condensable gas. Water seal is one of the most important safety device.It can prevent tempering, but also can judge of the cooling system, if cooling is not complete, there will be oil in the the water seal device.

5. Part of the tail gas produced by the cracking process is used to heat the reactor, and some of it is diverted into the air to burn. The DOING pyrolysis plant is also equipped with a odor removal tank, so the exhaust in the air is tasteless and pollution-free. 6. After the tire pyrolysis process ends , the carbon black is automatically discharged from the side of the reactor.

Three factors affecting oil yield:

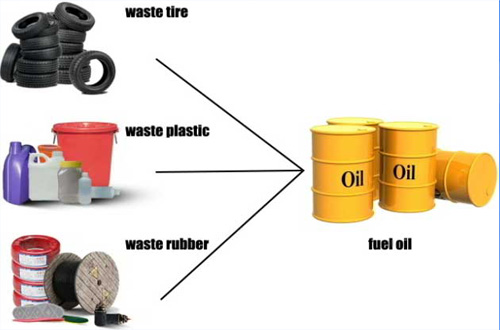

Different material to oil

Different material to oil

1 ,the raw material. Different material have different oil yield. For example ,the oil yield rate of big car tires is about 45% to 52%, while the pure PE plastics is 95%,and unclassified rubbers is approximately 35%.

2,Whether the oil in the material has been completely vaporized.

3, Whether Oil and gas are completely cooled.

Tire pyrolysis plant

Tire pyrolysis plant

DOING tire pyrolysis process plant can completely evaporate out of oil and gas in the raw materials, and the design of three condensers can guarantee that pyrolysis oil could be cooled thoroughly .Therefore, under with the same raw material, DOING tire pyrolysis plant yield more oil than other similar equipments.

- Features:

- Technical Data:

- Application:

Technical data of waste tire process pyrolysis continuous machine:

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

- Features:

- Technical Data:

- Application:

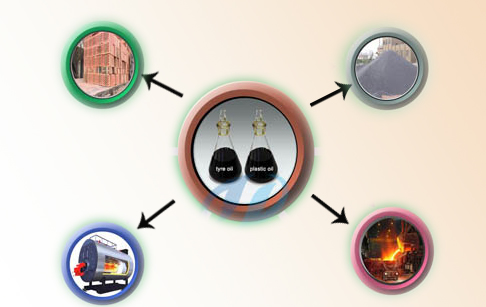

Fuel oil usage

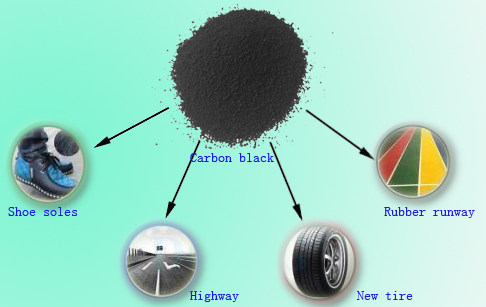

Fuel oil usage Carbon black

Carbon black Steel wire usage

Steel wire usageLeave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.