Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

News

-

DOING News

-

Industry News

Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

Can rubber be turned into oil? What's the conversion process?

2023-09-21 / Industry News / Leave Message / Chat Online

Rubber can be turned into oil. There is a machine on the market called pyrolysis machine, which can decompose waste rubber (such as waste tires, rubber cable sheath, rubber soles, rubber sheets, etc.) into fuel oil and carbon black at high temperature. Today we will take the DOING pyrolysis machine as an example to introduce the rubber into oil conversion pyrolysis process.

DOING waste rubber pyrolysis machine

DOING waste rubber pyrolysis machine

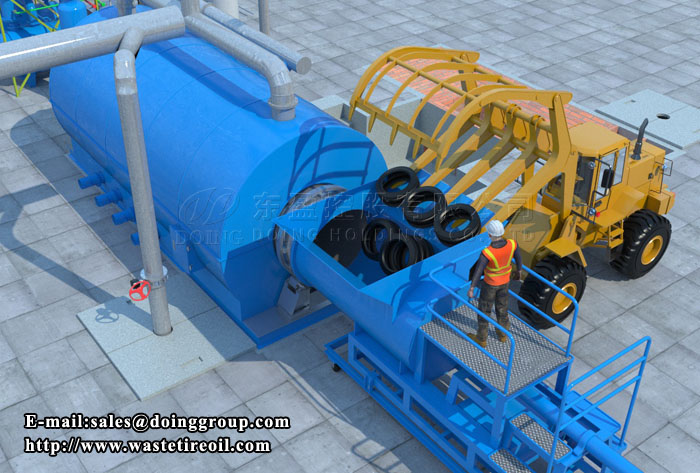

The first step is feeding. Our batch type waste rubber pyrolysis machine can directly process the whole waste rubber, while the continuous type requires processing it into rubber powder before feeding. The feeding method can be manual feeding or machine feeding.

If a grabbing machine is used in conjunction with an automatic feeding machine, the entire feeding process only requires two workers to operate, and the time is about 1.5 to 2 hours, which can fill a reactor with a daily processing capacity of 12 tons. There are many customers who choose auto feeders and save time and labor.

The feeding method of waste rubber tires

The feeding method of waste rubber tires

The second step is heating and pyrolysis. After the feeding is completed, the combustion burners need to be opened to heat the reactor.

1. By controlling the burners to maintain the temperature between 230-260degrees. This temperature range is the first oil output stage, which lasts about four hours.

2. Next is the constant temperature reaction stage, that is, the second oil output stage. Where the temperature will decrease and it needs to be controlled to gradually increase until the oil output decreases. At this time, the rubber in the reactor has basically completed pyrolysis.

3. Finally, heat it over high heat, ensuring that all the rubber can be converted into oil gas.

The waste rubber pyrolysis process

The waste rubber pyrolysis process

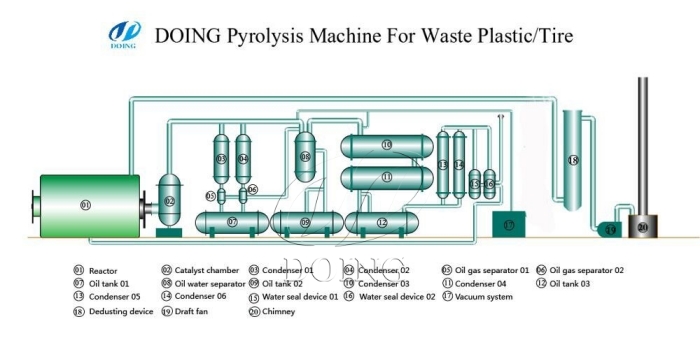

The third step is the condensation stage. And our condensation system is composed of two vertical condensers, one oil-water separator, two horizontal condensers, and two cooling towers. Through multiple condensation systems, it can ensure that all oil and gas can be condensed, ensuring a high oil rate. Besides, all condensers use circulating cooling water, achieving zero discharge of wastewater.

After all the oil gas is cooled into liquid oil, the oil from each sub oil tank can be pumped to the oil tank storage area. This liquid oil is rubber pyrolysis oil, which can be directly sold to the industrial plants as fuel for boiler heating, such as steel plants, cement plants, power plants, etc.

The uses of rubber pyrolysis oil

The uses of rubber pyrolysis oil

That's the rubber into oil conversion pyrolysis process of DOING pyrolysis machine. If you have any needs for our waste rubber pyrolysis machine, please contact us. We can provide you with a variety of models and processing capacities of pyrolysis machines. Also, DOING provides customized services and after sales services, such as customizing the material of the pyrolysis reactor, customizing the purchase plan that best meets your needs, arranging installation guidance and operation training services.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.