Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

News

-

DOING News

-

Industry News

Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

How to start continuous waste tyre pyrolysis plant in India?

2023-08-31 / Industry News / Leave Message / Chat Online

Waste tyre pyrolysis projects in India are not unfamiliar, as DOING began installing waste tyre pyrolysis plants in India more than a decade ago. In recent years, according to the feedback of our Indian customers, batch pyrolysis plants are no longer allowed in India, replaced by more advanced and environmentally friendly continuous pyrolysis plants. So how to start a continuous waste tyre pyrolysis plant in India?

1. Investigate your local market

When you are planning to invest in a continuous waste tyre pyrolysis plant, you need to investigate the market situation. First, investigate the source of waste tyres, find reliable suppliers of waste tyres in India, and then investigate the market and price of fuel oil and carbon black to calculate your profit.

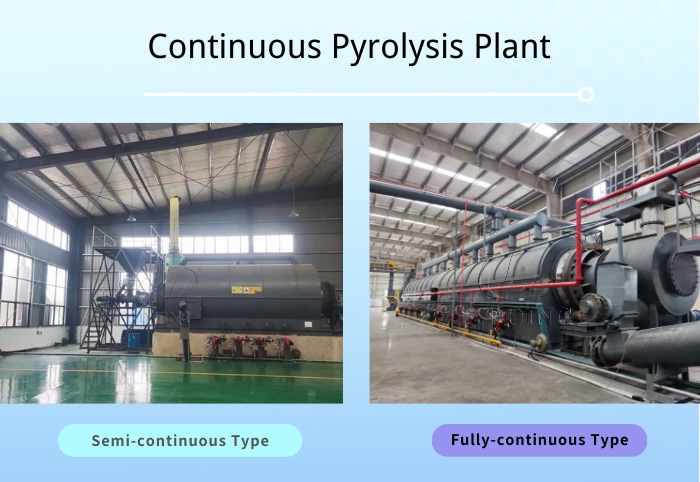

DOING semi-continuous & fully continuous pyrolysis equipment

DOING semi-continuous & fully continuous pyrolysis equipment

It's essential to guarantee a reliable waste tyre feedstock supply. If your raw material is enough, DOING fully continuous waste tyre pyrolysis equipment can run at least 30 days without stopping. And the processing capacity of DOING continuous pyrolysis equipment is from 10T to 50T(semi-continuous & fully continuous), you can choose the processing capacity of pyrolysis equipment according to the quantity of raw materials.

2. Apply for the required permits

After investigating the market, you need to go to PCB (Pollution Control Board) in India to know the process and the required information to apply for the required permits. If you need more detailed information about the continuous waste tyre pyrolysis plant, DOING can provide it for you.

3. Prepare sufficient funds

Once you have the permits, you will begin to prepare for continuous pyrolysis equipment procurement. The price of continuous pyrolysis equipment is higher than the batch design, because it is much better than batch design from the degree of automation, environmental protection and advanced. Most customers will choose to use their own savings to purchase. Of course, if you do not have enough funds, you can choose to find investors or choose to get the loan from the bank.

DOING continuous pyrolysis plant site

DOING continuous pyrolysis plant site

4. Prepare project land

For DOING waste tyre continuous pyrolysis plant, around 2000 square meters are enough for machine installation. Also, you can prepare more area for feedstock and finished product storage. In addition, the project land is best in the industrial park. If it is difficult to find an industrial park, it must be far away from residential areas.

5. Purchase continuous waste tyre pyrolysis equipment

When everything is ready, then you need to start the continuous waste tyre pyrolysis equipment procurement to achieve production. When you choose the pyrolysis equipment manufacturer, you need to consider the strength of the equipment manufacturer, the design features of the pyrolysis equipment, the after-sales installation service, etc. It is best to personally inspect and visit the continuous waste tyre pyrolysis equipment manufacturers.

Recommond reading: 15-50TPD fully continuous waste tire pyrolysis plant operation video

If you have any further questions about how to start a waste tyre continuous pyrolysis plant in India, please feel free to contact DOING. We will provide you with professional solutions and comprehensive assistance based on years of experience.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.