Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

News

-

DOING News

-

Industry News

Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

What's the best method for tank bottom sludge treatment?

2023-08-08 / Industry News / Leave Message / Chat Online

Oil sludge refers to a mixture of oil, water and solids, and tank bottom sludge is a kind of oil sludge. The common oil sludge treatment methods include pyrolysis, water washing, biological treatment, solidification treatment, incineration, etc. Among them, which of these oil sludge treatment methods is the best?

The answer is pyrolysis, because pyrolysis technology for oily sludge treatment can realize the environment and lower cost disposal of solids and recover as much oil as possible. Doing Company can provide complete sets of oil sludge treatment equipment pyrolysis plants to treat the sludge and recover the oil.

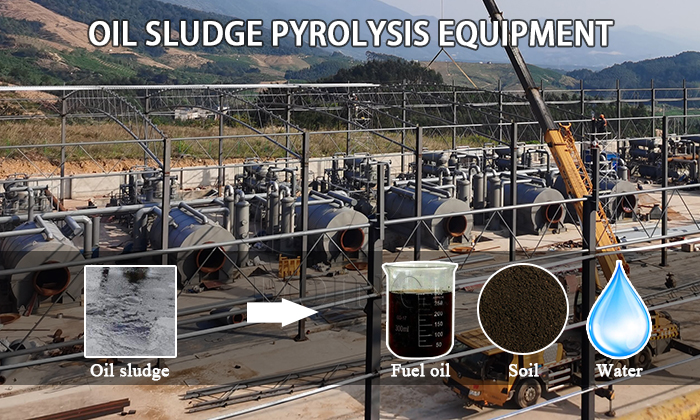

DOING oil sludge treatment equipment

DOING oil sludge treatment equipment

If your tank bottom sludge is high oil content, for example more than 40% oil, then you could choose stainless steel material reactor semi-continuous pyrolysis plant, which is more efficient.

If your tank bottom sludge is low oil content, then you could consider a normal reactor plate batch pyrolysis plant.

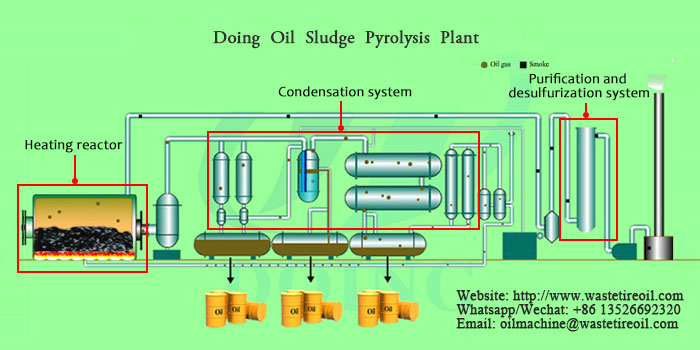

Both semi-continuous and batch-type pyrolysis plants can extract oil out from your tank bottom sludge, and the process is roughly the same. The following will introduce the DOING oil sludge pyrolysis process:

1. Feeding

Put the oil sludge into the hydraulic feeder, and the hydraulic feeder pushes the oil sludge into the pyrolysis furnace;

2. Heating

Heating the oil sludge in the pyrolysis furnace, after a period of time, oil and gas will be produced;

3. Condensation

The oil gas is condensed into oil through the cooling system;

The pyrolysis process of oil sludge

The pyrolysis process of oil sludge

4. Exhaust gas recovery and utilization

In the process of heating and pyrolysis, in addition to producing oil-gas, there will also be some combustible but non-condensable gas, which will be fully burned by the combustion machine at the bottom of the cracking furnace, and can also save fuel;

5. Smoke treatment

The smoke generated by combustion enters the environmental protection purification device, to ensure that the smoke discharge meets the environmental standard;

6. Discharging slag

The waste residue is automatically discharged through a fully sealed slag discharge device and then directly packed into bags. There is no dust pollution throughout the process.

DOING oil sludge pyrolysis plant

DOING oil sludge pyrolysis plant

DOING oil sludge pyrolysis plant can not only be used to treat tank bottom sludge, but also can be used to treat crude oil sludge, aste drilling mud, sediments, etc. If you are searching for oil sludge treatment equipment, you can contact us at any time. We're a top pyrolysis plant manufacturer in China, and we have cooperated with many customers from 90+ countries.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.