Philippines customer bought 10T

Contact Us

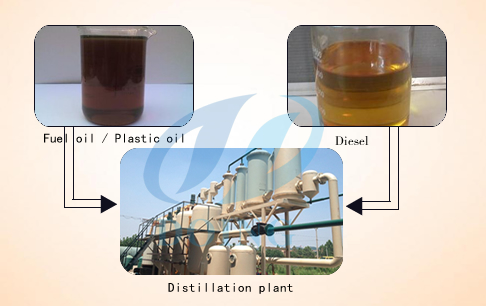

Waste tyre pyrolysis oil distillation process plant

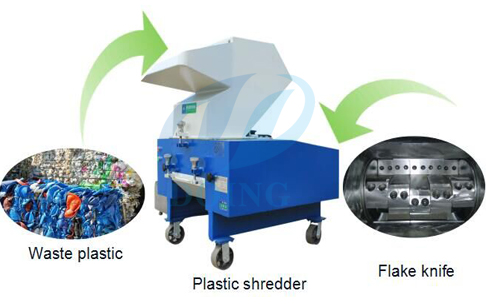

Waste tyre pyrolysis oil distillation process plant not only applied to tyre oil also can use for plastic oil and wste en...

Skype:bonniezhao2

+86-135-2669-2320

+86-371-56771821

WhatsApp:0086 135 2669 2320

- Features:

- Technical Data:

- Application:

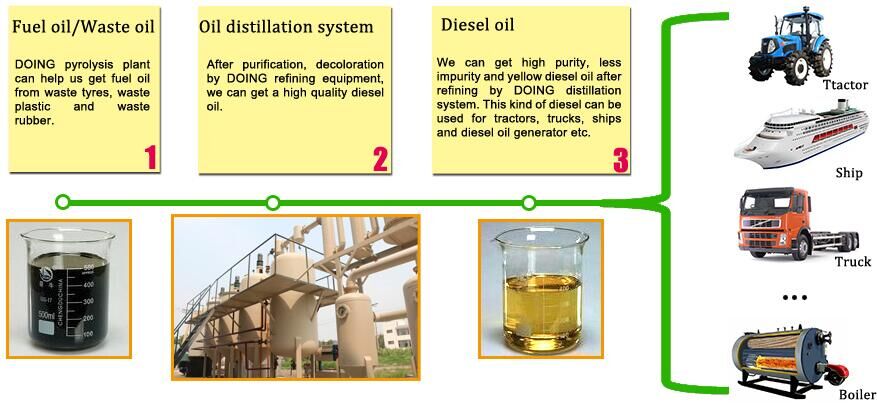

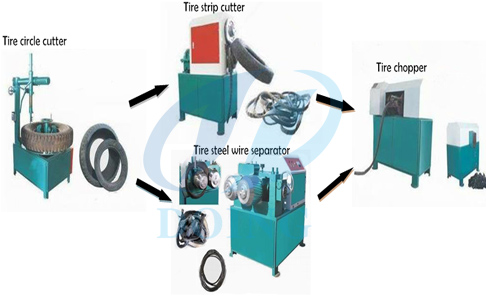

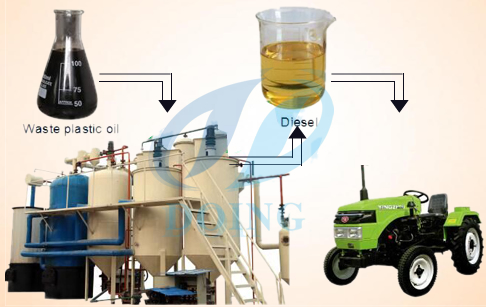

As we know, waste tyres cause harm to the environment, therefore, it is very important to properly handle them. With the help of pyrolysis plant and oil distillation process plant, we can achieve the process of waste tyre pyrolysis oil distillation process plant. First, through the tyre pyrolysis plant, we can get fuel oil, carbon black and steel wire. To further refine the fuel oil to diesel oil, we should put the fuel oil in the distillation equipment for further processing.

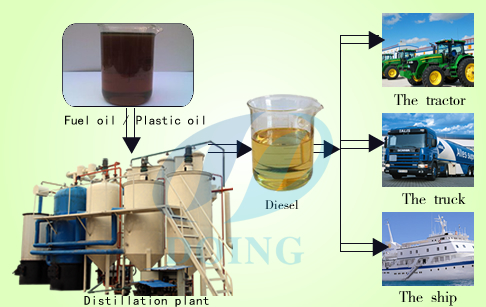

Waste tyre pyrolysis oil distillation process plantnot only applied to tyre oil also can use for plastic oil and wste engine oil.The final oil of waste tyre oil to diesel distillation plant can used for tractors ,trucks, ships and generator.

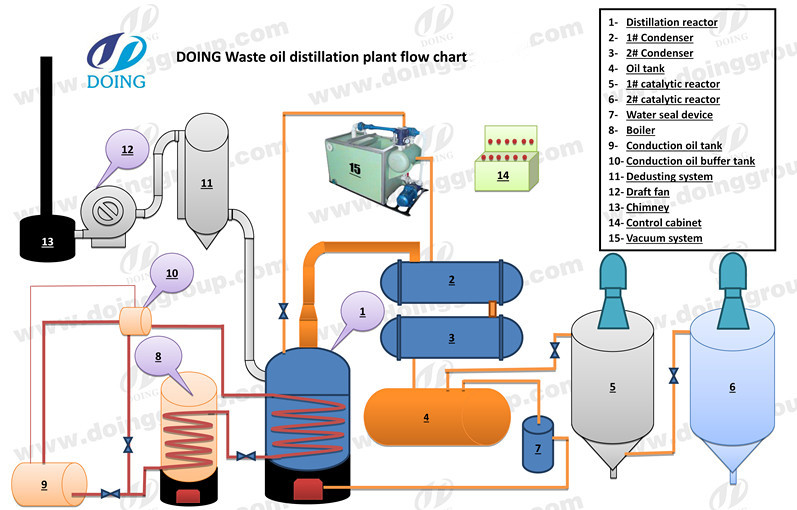

Waste tyre pyrolysis oil distillation process plant working process

Waste tyre Waste tyre pyrolysis oil distillation process plant working process

Waste tyre Waste tyre pyrolysis oil distillation process plant working process

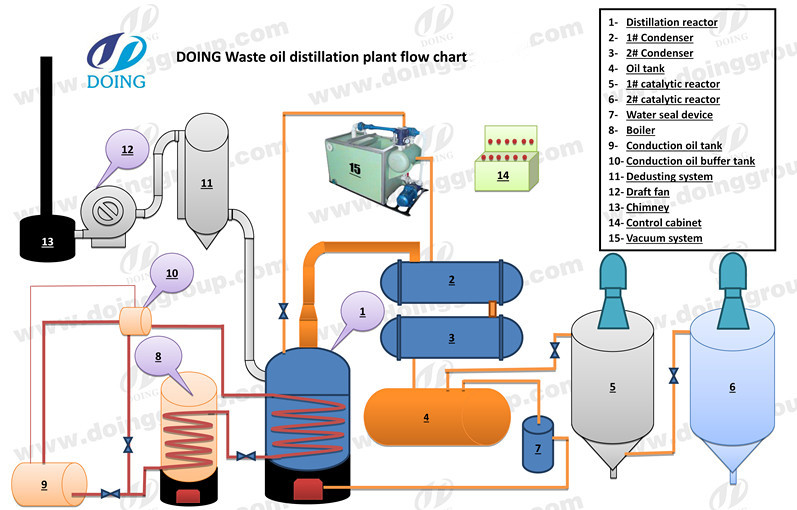

1. Put tyre oil/plastic oil/engine oil into distillation reactor with oil pump

2. Heating system works to heat waste oil over 170℃

3. Distillation oil gas produced and cooling down to pure distillation oil by condensers

4. After distillation, the distillation oil is pumped into odor-removal tank where catalysts used to remove the smell

5. Then oil go into color-removal tank for de-coloring with the special catalysts

6. Finally, you can get about 85% pure diesel oil.

Waste tyre pyrolysis oil distillation process plant

Waste tyre pyrolysis oil distillation process plantnot only applied to tyre oil also can use for plastic oil and wste engine oil.The final oil of waste tyre oil to diesel distillation plant can used for tractors ,trucks, ships and generator.

Waste tyre pyrolysis oil distillation process plant working process

Waste tyre Waste tyre pyrolysis oil distillation process plant working process

Waste tyre Waste tyre pyrolysis oil distillation process plant working process 1. Put tyre oil/plastic oil/engine oil into distillation reactor with oil pump

2. Heating system works to heat waste oil over 170℃

3. Distillation oil gas produced and cooling down to pure distillation oil by condensers

4. After distillation, the distillation oil is pumped into odor-removal tank where catalysts used to remove the smell

5. Then oil go into color-removal tank for de-coloring with the special catalysts

6. Finally, you can get about 85% pure diesel oil.