Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

Video

-

PLC control fully continuous pyrolysis technology 3D working video

-

14Ton waste oil recycling machine in Indonesia operation site

-

Fully continuous tire pyrolysis plant working process 1: waste tire pre-treatment

-

Semi-continuous tire pyrolysis machine process flow 3D video

-

Waste Oil Sludge Thermal Decomposition Units(TDU) Running Site Live Video

-

50TPD fully continuous tyre pyrolysis plant in India display video

-

Three types of DOING waste tire pyrolysis plants real shot display video

-

Fully continuous waste tire pyrolysis plant project installed by DOING introduction video

-

-

12 sets of 12tpd waste tire pyrolysis plants installed in China video

Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

PLC control fully continuous pyrolysis technology 3D working video

2024-09-12 / Video / Get Price / Chat Online

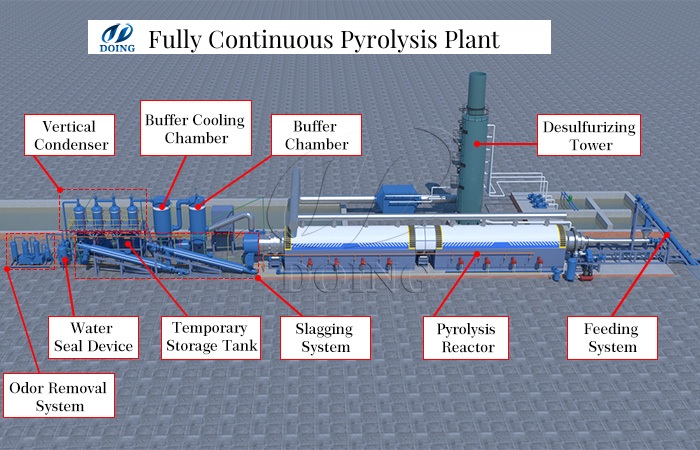

This video mainly shows the equipment details of the PLC-controlled fully continuous pyrolysis technology and the overall infrastructure of the project site. By watching the video, you can also understand the basic process flow of the operation of the fully continuous pyrolysis machine.

Process flow of PLC control fully continuous pyrolysis technology:

1. Feed the pre-treated waste feedstocks. The waste raw materials, such as waste tires, rubber powder processed from waste rubber, and crushed waste plastic raw materials, are transported into the reactor through auto-feeder.

2. Continuous pyrolysis: continuous heating of the raw materials, and continuous operation; At present, the new upgraded process of fully continuous pyrolysis machine adopts hot air furnace heating, which has a more uniform heating temperature.

Fully continuous pyrolysis machine confiragutaion details

Fully continuous pyrolysis machine confiragutaion details

3. Pyrolysis oil and gas condensation. This is a fully automatic process. After high-temperature pyrolysis, the oil-containing substances in the materials are basically converted into oil gas; the multi-stages condensors further exchange the oil gas into oil and non-condensable syn-gas effectively. The syn-gas will be recovered as the fuel for heating pyrolysis reactor.

4. Continuous discharge: Continuous and automatic uninterrupted slag discharge throughout the process. After the waste raw materials arepyrolyzed, carbon slag such as carbon black is left. These slag materials are discharged through the automatic slag discharger and then collected.

5. Purify the exhaust gas. The exhaust gas from heated combustion is comprehensively treated by the exhaust gas purification system and then discharged in compliance with the standards.

If you have requirements for pyrolysis machines with high automation, small staffing requirements, and 24-hour continuous feeding advantages, then DOING PLC fully continuous pyrolysis technology is a good choice!

Previous: Nothing

Next: 14Ton waste oil recycling machine in Indonesia operation site

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.