Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

Video

-

DOING Waste Thermal Pyrolysis Equipment Feed-stocks Processing Demonstration

-

Semi-continuous and fully automatic pyrolysis equipment differences introduction video

-

DOING Advanced Continuous Pyrolysis Technology For Waste Recycling Display Video

-

PLC control fully continuous pyrolysis technology 3D working video

-

14Ton waste oil recycling machine in Indonesia operation site

-

Fully continuous tire pyrolysis plant working process 1: waste tire pre-treatment

-

Semi-continuous tire pyrolysis machine process flow 3D video

-

Waste Oil Sludge Thermal Decomposition Units(TDU) Running Site Live Video

-

50TPD fully continuous tyre pyrolysis plant in India display video

-

Three types of DOING waste tire pyrolysis plants real shot display video

Product

Project Case

-

DOING® Group|100 TPD Continuous Tire Pyrolysis Plants Installed for Repeat Client in China

-

Customized 1 Ton/Day Continuous Plastic Pyrolysis System Delivered for Korean Client

-

DOING DY-15 Waste Tire Pyrolysis Machine Project Successfully Installed in Kenya

-

DOING 45,000 Tons/Year Waste Plastic Pyrolysis Project in Vietnam Successfully Commissioned

-

DOING Tire & Plastic Pyrolysis Distillation Plant Successfully Installed in Fiji

-

DOING 50TPD Continuous Oil Sludge Pyrolysis Production Line Successfully Installed in China

-

DOING Installed 15-Ton Tank Bottom Sludge Pyrolysis Equipment for Colombian Repeat Client

-

DOING 30TPD Mazut Oil Distillation Plant Successfully Installed in Kazakhstan

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

Fully continuous tire pyrolysis plant working process 1: waste tire pre-treatment

2024-05-28 / Video / Get Price / Chat Online

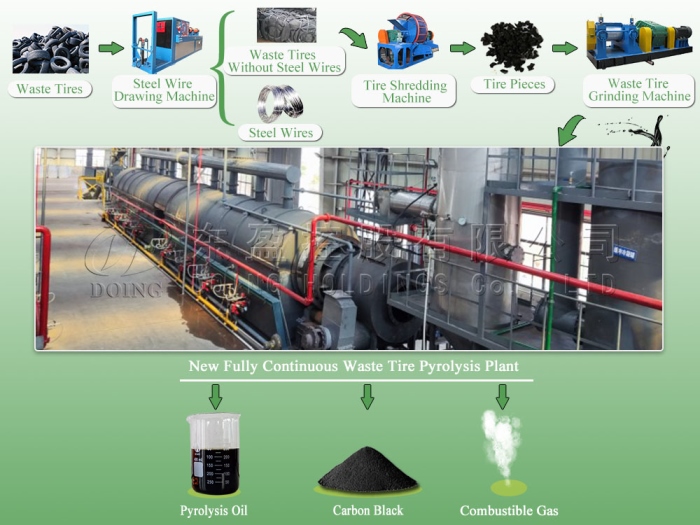

This video series mainly shows the actual working process of the fully continuous tire pyrolysis plant. This video mainly shows the first section: the waste tire pretreatment section and the equipment required for the waste tire pretreatment process.

The key technology of the continuous waste tire pyrolysis plant lies in continuous production. In order to facilitate the continuous feeding, continuous pyrolysis and continuous oil output of waste tires, the waste tires need to be pretreated by waste tire to rubber powder processing machine. The rubber powder production machine mainly consists of three parts: tire decomposition equipment, waste tire shredding and crushing machine, and rubber powder screening magnetic separator.

Waste tire to rubber powder processing machine for continuous pyrolysis

Waste tire to rubber powder processing machine for continuous pyrolysis

First, the waste tires are shredded into pieces of about 3.5 cm through decomposition equipment, including tire sidewall cutter, tire strip cutter, tire shredding machine; then, the tire fragments enter the grinding mill through the conveyor belt and are crushed and ground into rubber powder particles of about 18 mesh; then, the tire rubber powder will enter the vibrating screen and magnetic separator in sequence, and the steel wire mixed rubber powder particles will be passed through two sieve beds to separate the steel wire and rubber powder. The fine materials are then magnetically separated by magnetic rollers to separate the steel wires, and finally a relatively pure rubber powder is obtained. The rubber powder enters the silo for storage through the conveying equipment. This is the process flow of the entire production line in the waste tire pretreatment section.

Fully continuous tire pyrolysis plant working process

Fully continuous tire pyrolysis plant working process

Henan Doing Company provides the waste tire petreatment equipment-waste tire to rubber powder processing machine, as well as pyrolysis plant and pyrolysis oil to diesel distillation plant. There are large, medium and small models to choose from, and we also support customization services. Welcome to inquire!

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.