Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

FAQ

-

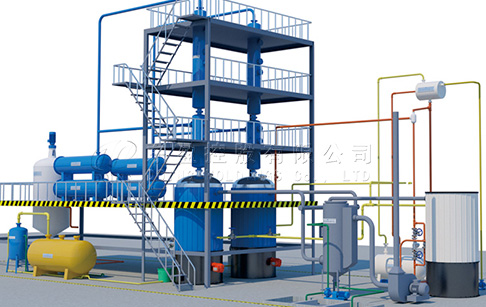

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Waste Oil Distillation Machine

Waste oil distillation machine can convert waste tyre oil, plastic oil, and waste engine oil to diesel. In some country,...

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

- Features:

- Technical Data:

- Application:

Waste oil distillation machine can convert waste tyre oil, plastic oil, and waste engine oil to diesel. In some country, waste oil to diesel distillation plant also named waste oil refining machine, oil distillation plant, waste oil recycling machine, etc.

Here distillation is refered to the chemical engineering processes and other facilities used in oil refineries to distills the incoming crude oil, pyrolysis oil and waste oil into useful products such as diesel oil and fuel oils, gasoline or petrol, jet fuel, etc. With the pursuit of higher oil quality, waste oil distillation machine has become a hot and highly profitable green project, which cost low, collect raw material easily and convert pyrolysis oil to diesel or gasoline efficiently (oil recovery rate is about 90%).

Waste oil distillation machine

Waste oil distillation machine

Raw material of waste oil distillation machine

Waste oil distillation machine can be application variety of waste oil, such as used engine oil, slag black oil, waste motor oil, pyrolysis oil and so on.

Variety of waste oil

Variety of waste oil

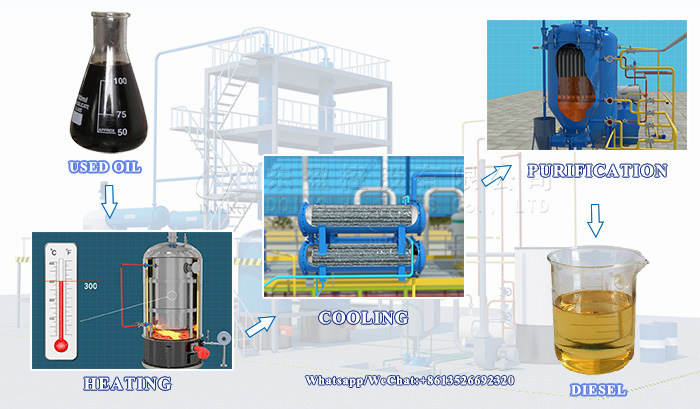

Main working process of waste oil distillation machine

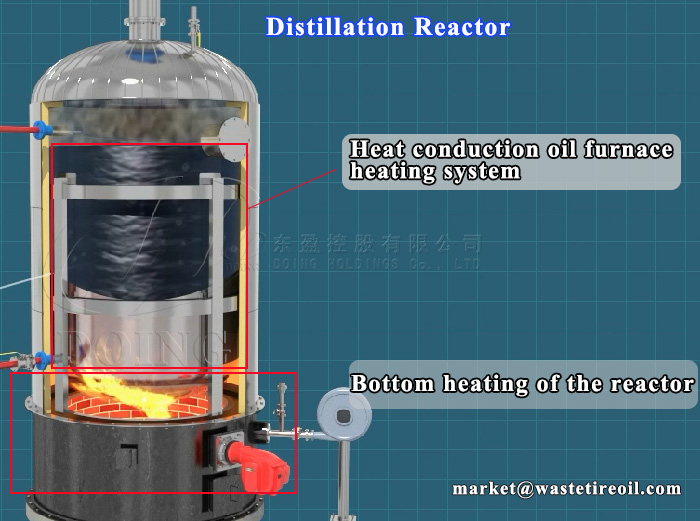

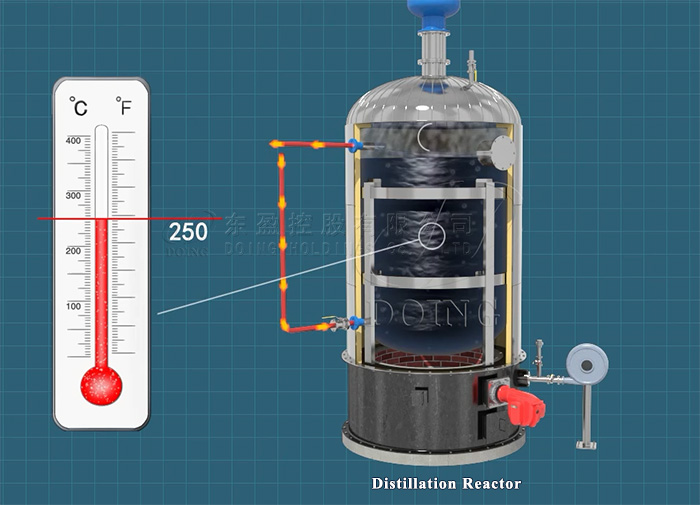

♦ Heating

DOING waste oil distillation machine adopt a dual heating system. The heat-conducting oil and the burner heat the used oil at the same time. Which makes heating time only 2 hours the used oil needs to be heated to over 200 ℃, Then the used oil will be turned into oil gas and steamed into the condenser. This design make heating more efficient and save heating time, which make preheating time only 2 hours.

Dual heating system

Dual heating system

♦ Cooling

When the temperature exceeds 200℃, it should be maintained for 8-10 hours. The oil gas will flow into cooling system through the buffer tank. There are total 4 condensers including two vertical condensers and two horizontal condensers. There are 37 tubes each condenser, so the total is 74 tubes, which greatly increase cooling area, and make sufficient cooling effect and get the high oil output.

♦ Purification

We set up clay bleaching system to filter out other impurities in diesel oil with clay to make the color of diesel more clear. Finally, you can get about 90% pure diesel oil.

Main working process of waste oil distillation machine

Main working process of waste oil distillation machine

Advantage of waste oil distillation machine

→ Minimize the process of heating

By using the dual heating system, our client can save much time to heat the whole reactor, and the heating speed is faster and the temperature can keep the reactor hot for longer time, so the whole process is faster with less fuel.

→ Environmental

All the system is sealed, in the terms of smoke and smell, our new design waste oil distillation machine is equipped with desulfurization & purification tower. After the treatment of desulfurization & purification tower, the final emission can reach the standard.

→Easy to clean up

Due to the vertical reactor design, slag is very easy to clean which will be down through the bottom of the vertical reactors. So the cleaning operation is easier.

Vertical distillation reactor

Vertical distillation reactor

FAQ of waste oil distillation machine

►Q: What’s the raw material and final products of waste oil distillation machine?

A: The raw material could be waste tire oil, waste plastic oil and waste engine oil. And the final products will be diesel and asphalt.

►Q: What’s the usage of refined diesel?

A: It could be used in diesel generators, diesel burners, tractors and big trucks etc.

►Q: How many countries have you installed your waste oil distillation machine?

A: We have installed distillation machine in more than 60 countries. Like Mexico, Jamaica, Ecuador, Malaysia, Pakistan, Lebanon etc.

►Q: What’s the capacity of waste oil distillation machine?

A: We have different capacities including 500kg, 1T, 5T, 10T, 15T, 20T. If you have special needs, we can also provide customized service. The most popular capacity are 5T and 10T. Many of our customers will combine pyrolysis plant to do projects. Usually 5T waste oil distillation machine can match one set 10T waste tire and plastic pyrolysis machine and 10T waste oil distillation machine can match 2 sets waste tire and plastic pyrolysis machines.

►Q: What’s the oil yield rate of waste tire oil and waste plastic oil?

A: The oil yield rate of waste tire and waste plastic oil is about 85%. The oil yield rate of waste engine oil is 90% or more.

►Q: What’s the other 10%-15% after distillation?

A: The other 10%-15% is alphalt and little waste gas. Asphalt can be used to make road or water proof material. And the waste gas can be used to heat the boiler or reactor as fuel.

- Features:

- Technical Data:

- Application:

Technical parameter of waste oil distillation machine

| Technical parameter of waste oil distillation machine | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

- Features:

- Technical Data:

- Application:

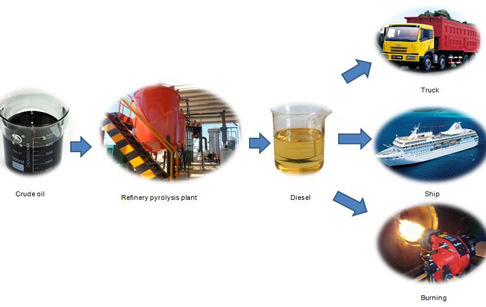

Final products application from waste oil distillation machine There are two main final products of waste oil distillation machine. One is diesel oil, and the other is asphalt. Moreover, these two final products both have a wide range of applications.

1. Diesel

The diesel oil obtained from waste oil distillation machine can be directly used in tractors, trucks, ships, boilers, diesel generators, etc.

Diesel applications

Diesel applications

2. Asphalt

The asphalt is often used for paving, but it can also be further refined by asphalt plant to get fuel oil.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.