Product

Project Case

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

-

India 50TPD Fully continuous rubber pyrolysis machine installed

-

DOING 15 TPD semi-continuous tire pyrolysis equipment installed in Indonesia

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

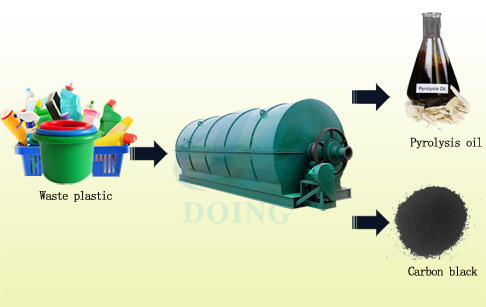

Waste plastic to diesel plant

The crude oil product that you obtain from the pyrolysis process can be used as furnace oil but it isn't sufficiently pu...

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

- Features:

- Technical Data:

- Application:

Despite its amazing properties of strength, durability and its light weight, plastics have a major drawback: they can take up to 500-1000 years to naturally degrade. So if plastic had been discovered 500 years ago, and if Shakespeare used to brush his teeth, then his toothbrush would still be lying somewhere in someplace!

Waste oil

So what do we do with these ever-growing mounds of plastic waste? Bury plastic underground? Burn it? Or launch it into space! These solutions are more disastrous than the problem itself.

The basic pyrolysis process goes as follows:

1. Shredding or compressing for better feeding

Firstly, the waste material must be segregated and, if possible, be cleaned. Then it is shredded to speed up the reaction and to ensure that the reaction is complete.

2. Anaerobic heating

The shredded material must be heated in a controlled manner in an oxygen-free reactor. One of the most crucial factors in this operation is maintaining the right temperature(~430C for plastic) and the rate of heating, as they define the quality and the quantity of the final product.

3. Condensation

The gas that comes out from the reactor must be condensed by passing it through a condensation system, which the recycled water cooling system is the most commonly used method at present.

The crude oil product that you obtain from the pyrolysis process can be used as furnace oil but it isn't sufficiently pure for engines. If you want to use it as engine fuel, you need to extract and purify the desired products from the crude oil through a fractional distillation process.

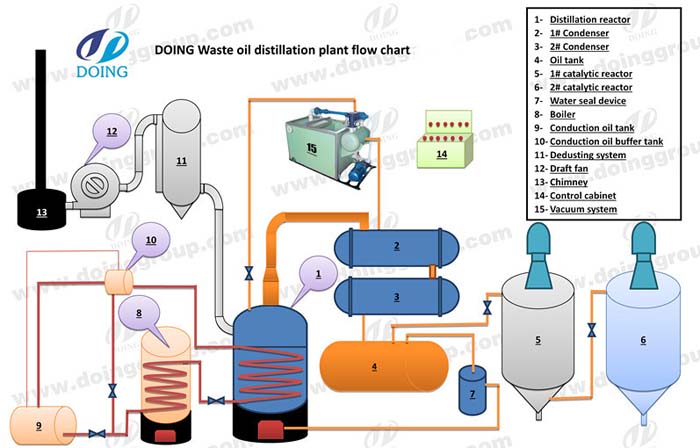

And below are the normal distillation process by waste plastic to diesel plant:

Working process of waste plastic to diesel plant

2.Heating

3.Condensation

4.Chemical processing

Waste plastic to diesel plant

So through this process of pyrolysis and distillation, the bane of abhorrent plastic waste, can now become a boon and a source of abundant fuel. This will reduce plastic in landfills, reduce emissions and be a reliable alternative to the depleting fossil fuels. Don't trash your future. Act now!

- Features:

- Technical Data:

- Application:

| Technical parameter of waste plastic to diesel plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

- Features:

- Technical Data:

- Application:

Diesel application

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.