Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Oil Sludge Pyrolysis Plant

Oil sludge pyrolysis plant is a new type of green sludge recycling technology. The main products you get from this plant...

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

- Features:

- Technical Data:

- Application:

Oil sludge is a by-product of oil mixed with water, silt and solid sediments in the mining process. It is harmful to humans and the environment, so it must be treated reasonably. The oil sludge pyrolysis plant has attracted extensive attention from researchers around the world due to its advantages of thorough treatment and high energy recovery rate.

DOING oil sludge pyrolysis plant

DOING oil sludge pyrolysis plant

Oil sludge pyrolysis plant is a new type of green sludge recycling technology. The main products you get from this plant are pyrolysis oil, soil and water. The most important influencing factor of the oil sludge pyrolysis plant is the large oil output, the large oil output, and the high benefit. After years of research and improvement, DOING company has achieved greater success in the cooling system and achieved a higher yield.

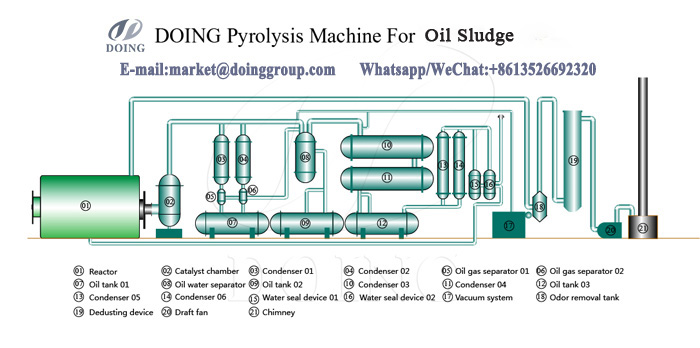

The main working process of oil sludge pyrolysis plant

Main working process of oil sludge pyrolysis plant

Main working process of oil sludge pyrolysis plant

1. Feed oil sludge into pyrolysis reactor then make sure the door of pyrolysis reactor is closed.

2. Heat the reactor by using oil, gas, etc. as heating materials. The reactor will be slowly heated, and when the temperature reaches about 250°C, oil gas will be formed.

3. The oil gas coming out from the reactor then goes to condensing system and becomes liquid oil. We adopt circulating water tube condensation, which has a larger contact area and have good cooling effect, and it can improve oil output efficiency.

4. The gas that cannot be liquefied under normal pressure will pass through the environmental protection device to remove the polluting gas contained, and then used to heat the pyrolysis reactor which can save energy for the whole working process.

5. Then discharged the soil automatically.

- Features:

- Technical Data:

- Application:

| Technical parameter of oil sludge pyrolysis plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-10 | DY-1-12 |

| 2 | Raw material | Oil Sludge | Oil Sludge | Oil Sludge |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 10 ton | 12ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2600×6600 | 2800×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 32T | 35T |

| Prepared by customer about oil sludge pyrolysis plant | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60? /month | |

| 7 | Total power | 19kw | |

| 8 | Land area |

35m*15m |

|

- Features:

- Technical Data:

- Application:

Applications of End Products

We can get fuel oil, solid waste, and water from oil sludge pyrolysis plant. Then what can we do with those end products?

End products of oil sludge pyrolysis plant

End products of oil sludge pyrolysis plant

1. Fuel oil

It is of high quality, so you can use it as fuel directly. Besides, you can also employ a set of waste oil distillation machine to refine it into diesel.

2. Solid waste

Most of the end products are solid waste, which can be used to make construction materials.

DOING oil sludge pyrolysis plant are popular among the customers because of the mature design, reasonable price and considerate service. Interested parties can leave a message on the website or contact us directly.

Previous: Nothing

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.