Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Waste Plastic Pyrolysis Plant

Waste plastic pyrolysis plant is a new method to recycle plastic safely and environmentally. By using the waste plastic ...

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

- Features:

- Technical Data:

- Application:

Waste plastic pyrolysis plant is a new method to recycle plastic safely and environmentally. By using the waste plastic pyrolysis plant, we can get fuel oil from the plastic waste, and we can also get the carbon black and combustible gas, all of which have a wide range of applications.

Waste plastic pyrolysis plant and end products

Waste plastic pyrolysis plant and end products

According to the demands of different customers, DOING provide different capacity of waste plastic pyrolysis plant for customers, including 1T, 5T, 10T, 12T, 15T. Among them, 12T and 15T are our best-selling models.

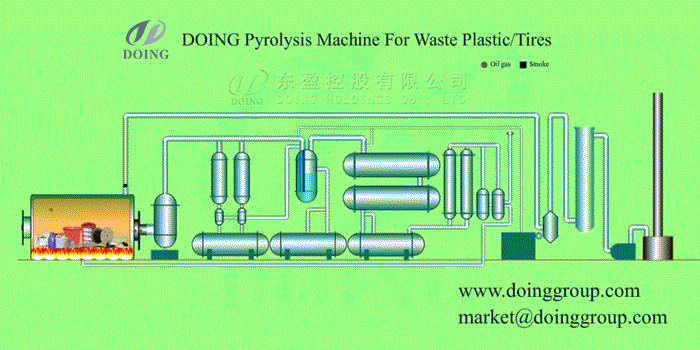

How Does the Waste Plastic Pyrolysis Plant Work?

The pyrolysis process of waste plastic pyrolysis plant

The pyrolysis process of waste plastic pyrolysis plant

1. Before put the waste plastic into the pyrolysis reactor, you need make sure that the water content can reach the standard. Otherwise, you should dry it first.

2. Heat the pyrolysis reactor with fuel, coal, or Natural gas. When the temperature reaches a certain degree, the oil gas will be produced. The most appropriate oil produced temperature is about 300 degrees Celsius.

3. The oil gas will flow into the cooling system and be cooled into a liquid oil.The un-combustible gas produced will be processed by the hydroseal, then it can heat the reactor.

4. Last, When the temperature in the reactor drops,carbon black can be discharged.

- Features:

- Technical Data:

- Application:

| Technical parameter of waste plastic pyrolysis plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-10 | DY-1-12 |

| 2 | Raw material | Waste plastic | Waste plastic | Waste plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2600×6600 | 2800×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 32T | 35T |

| Prepared by customer about waste plastic pyrolysis plant | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60? /month | |

| 7 | Total power | 19kw | |

| 8 | Land area |

35m*15m |

|

- Features:

- Technical Data:

- Application:

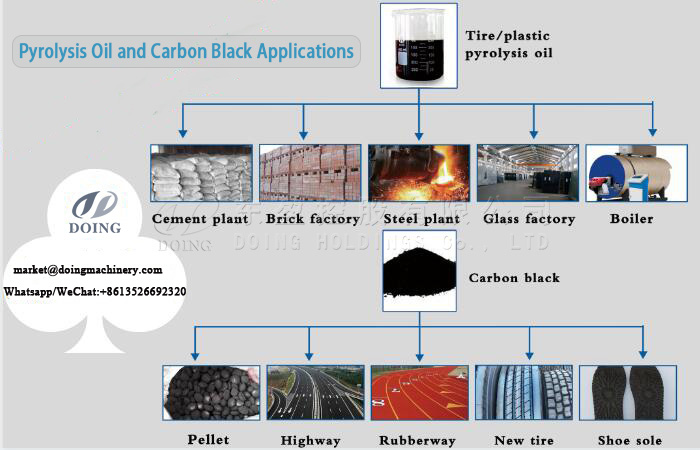

End products applications

1. Fuel oil

It is mainly used in steel plants, boiler heating, heavy oil generators, cement plants. It also can be refined to diesel oil with the help of pyrolysis oil distillation plant.

2. Carbon black

Carbon black can be used for pressure ball burning and refined milling. Which refined flour and can be used for new tires, rubber soles, pigment manufacturing materials.

End products applications

End products applications

The exact proportion depends on the type of waste plastics. This project can achieve 100% recycling of waste plastics. You can not only get economic benefits, but also improve the local environment and avoid garbage pollution.

Previous: Oil Sludge Pyrolysis Plant

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.