Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Waste Tyre Pyrolysis Plant

Waste tyre pyrolysis plant can solve the environmental problem which caused by a large number of waste tyres. And most i...

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

- Features:

- Technical Data:

- Application:

DOING has effective and environmental friendly waste tyre pyrolysis plant for sale. It can solve the environmental problem which caused by a large number of waste tyres. And most importantly, it will bring you considerable profits if you invest in it. In fact, a number of investors are already working on this waste tyre pyrolysis project.

Waste tyre pyrolysis plant project.

Waste tyre pyrolysis plant project.

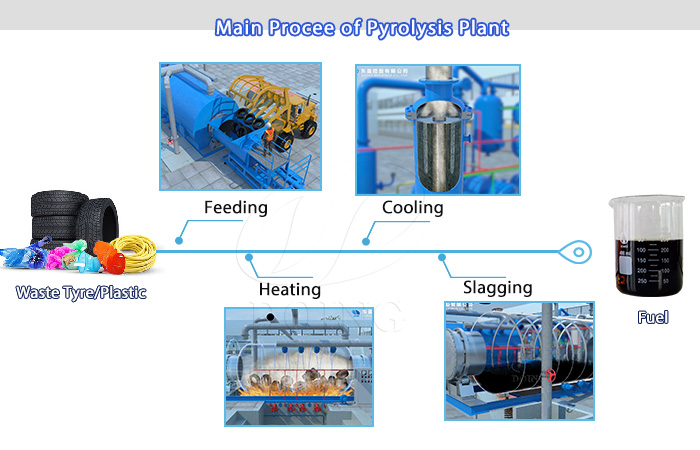

The main pyrolysis process of waste tyre pyrolysis plant

1. Put the waste tyres into the reactor and rotate the reactor clockwise, then seal the inlet door to ensure no gas leakage.

2. Heat the pyrolysis reactor slowly with heating materials. When the temperature reaches about 250 degrees, the waste tyre will be pyrolyzed and produce oil gas.

3. Oil gas from the reactor enters the condensing system, which is cooled down to liquid oil. Then collect liquid oil by the storage tank. Gases that cannot be liquefied under normal pressure will be recovered to the combustion system through a safety device. The gas can be used as fuel to heat the reactor.

4. After the liquid oil is collected, the reactor temperature will decrease. When the temperature drops to about 40 degrees, we can expel carbon black and steel wire.

The main pyrolysis process of waste tyre pyrolysis plant

The main pyrolysis process of waste tyre pyrolysis plant

Why Choosing DOING Waste Tyre Pyrolysis Plant

1. High quality and environment protection

Compared with the other tyre pyrolysis plant, the quality of the final products of waste tyre pyrolysis plants is qualified. They can be used or reprocessed safely without any danger or pollution to the environment.

2. Save labor

Even though DOING waste tyre pyrolysis plant is a high-tech tyre recycling plant, it is very easy to operate. So you can reduce a lot of labor cost and get a higher profit at the same time.

3. A variety of models are available

In order to meet the needs of different customers, we have designed different models of waste tyre pyrolysis plant. As shown below.

We can provide different scales and levels waste tyre pyrolysis plant. You can choose a continuous waste tyre pyrolysis plant if you need a large amount of output and capacity. When your raw material handling capacity is moderate, then you can choose batch tyre pyrolysis plant.

DOING project cases of waste tyre pyrolysis plant

Recent years, DOING waste tyre pyrolysis plant have been sold widely across the world, i.e. Malaysia, Mexico, Lebanon, Indonesia, Brazil , the Philippines and Turkey, etc. It has accumulated more than 60 countries. Here are some examples in some countries.

DOING waste tyre pyrolysis plant cases

DOING waste tyre pyrolysis plant cases

So we have rich experience in setting up waste tyre pyrolysis plant in different countries all over the world. If you are interested in our waste tyre pyrolysis plant, we can make a specific business project plan for you no matter which country you are from.

- Features:

- Technical Data:

- Application:

Technical parameters of DOING waste tyre pyrolysis plant

| Technical parameter of DOING waste tyre pyrolysis plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-10 | DY-1-12 |

| 2 | Raw material | Waste rubber, waste tyre | Waste rubber, waste tyre | Waste rubber, waste tyre |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 10 ton | 12 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2600×6600 | 2800×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 32T | 35T |

| Prepared by customer about rubber tyre pyrolysis machine | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60? /month | |

| 7 | Total power | 19kw | |

| 8 | Land area |

35m*15m |

|

- Features:

- Technical Data:

- Application:

Final products and their usage

| NO | Name | Percentage | Usage |

| 1 |

Fuel oil |

45% |

1.Can be sold directly; 2.Can be as fuel; 3.Can be used industrial and commercial purposes. |

| 2 | Carbon black | 30% |

1. Can be sold directly; 2. Can be used electric cable jacketing,black nylon bag, rubber additive |

| 3 | Steel wire | 15% |

1. Can be sold directly; 2.Make steel bloom by use hydraulic press-packing. |

| 4 | Oil gas | 10% |

1. Can be as fuel burn by use gas burning system; 2. Extra gas also be storage as fuel for other heating. |

Previous: Waste Plastic Pyrolysis Plant

Next: Nothing

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.