With our life being better and better, we use more and more plastic products for its cheap price, light weight easily manufacturer. Also we are surfing the pollution the waste plastic/tyre brings. Many of us have no idea about the waste. Landfill will pollute the ground and stay underground for a very long time to breed virus. If we burn the waste plastic. It will pollute the environment and generate toxic gas. We are of great honor to introduce the plastic/tyre to oil technology.

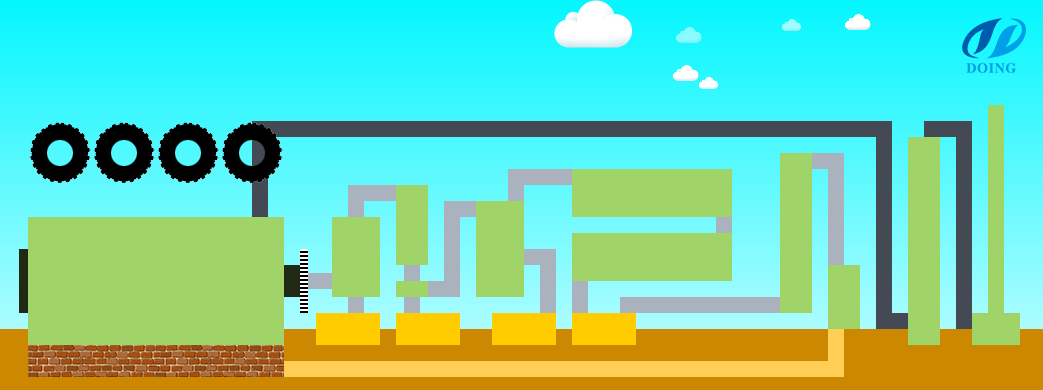

Waste tyre pyrolysis plant to oil technology is mainly to convert the waste plastic/tyre to crude oil. Also called waste tyre recycling plant, waste tyre recycling machine, waste tyre and so on. Usually there are two machines used together. The waste tyre pyrolysis plant to oil can convert the waste plastic/tyre to tyre oil (also named plasticoil). Then the curde oil distillation machine will convert the crude oil (plasticoil, tireoil) into diesel oil. In this step the oil is of great quality can used directly for car, motor, and bus and so on. Among all the advantages the raw material of the waste tyre pyrolysis plant to oil is easily achieved and cheap. Thus making the equipment much profitable.

The waste tyre pyrolysis plant to oil:

This equipment heats the waste in a reactor which is made of Q245R.Indirect heating ensure the safety and the waste plastic or/tyre will vaporize the solid. The rubber is softened after which the rubber polymers continuously breakdown into small molecules. Then the vapors can be burned directly in the reactor, or it can be condensed into oily type liquid. Usually, it is called crude oil. During the conversation there are some vapors which cannot be condensed will be recycled to heat the reactor itself. It is energy saving. Well designed dedusting system ensures no pollution to the environment.

Crude oil distillation plant; this is a process from crude waste tire oil to diesel oil. We can get high quality diesel oil accordingly.

|

Technical parameter of Waste tyre pyrolysis to oil plant |

|

|

Items |

Contents |

|

1 |

Equipment type |

DY-1-6 |

DY-1-8 |

DY-1-10 |

|

2 |

Raw material |

Waste tyre ,waste rubber,waste plastic, |

|

3 |

Structural form |

Horizontal rotation |

Horizontal rotation |

Horizontal rotation |

|

4 |

24-hour Capacity |

6 ton |

8 ton |

10 ton |

|

5 |

Oil yield |

2.7-3.3ton |

3.6 -4.4ton |

4.5 -5.5ton |

|

6 |

Operating pressure |

Normal |

Normal |

Normal |

|

7 |

Material of pyrolysis Reactor |

Q245R |

Q245R |

Q245R |

|

8 |

Thickness of pyrolysis Reactor |

16mm |

16mm |

16mm |

|

9 |

Rotate speed of pyrolysis Reactor |

0.4turn/minute |

0.4turn/minute |

0.4turn/minute |

|

10 |

Total power |

19KW |

19KW |

19KW |

|

11 |

Mode of cooling |

Water cooling |

Water cooling |

Water cooling |

|

12 |

Cooling area of condenser |

100sqm |

100sqm |

100sqm |

|

13 |

Kind of transmission |

Internal gear drive |

Internal gear drive |

Internal gear drive |

|

14 |

Noise dB(A) |

≤85 |

≤85 |

≤85 |

|

15 |

Size of Reactor(D×L) |

2200×6000 |

2200×6600 |

2600×6600 |

|

16 |

Working form |

Intermittent operation |

Intermittent operation |

Intermittent operation |

|

17 |

Delivery time |

20days |

20days |

20days |

|

18 |

Weight |

27T |

30T |

35T |

The waste tyre pyrolysis to oil plant is used to convert the waste tyre to oil,the plant is mainly used to dispose the waste tyres,the machine can convert the waste tyre to oil.

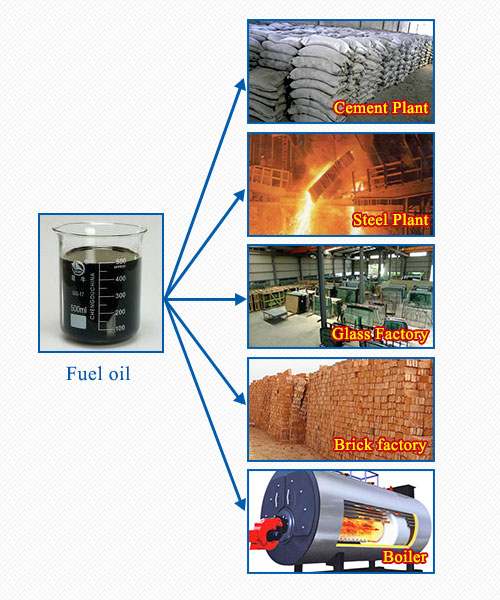

The pyrolysis oil is a good energy for heating,it is a good fuel oil.The pyrolysis oil is used in glass factory,cement factory,brick factory,especially in steel factory.